JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

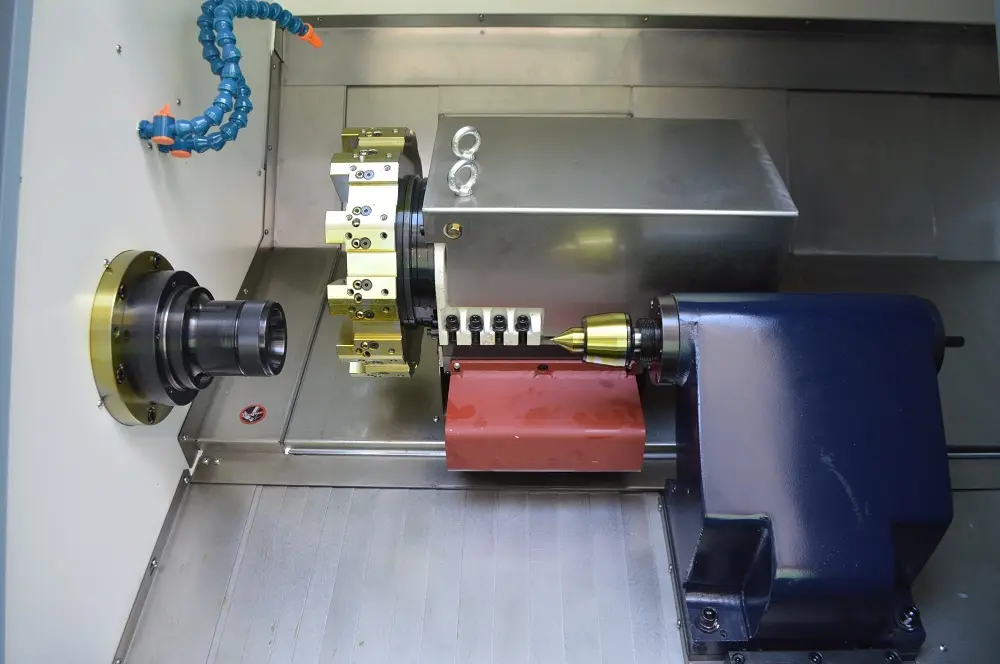

JSWAY professional turret lathe with tailstock for workplace

1. The raw materials of JSWAY 2 axis cnc lathe machine are carefully chosen. The production process of these materials are strict and their quality reaches the international standards, which helps it withstand the test of the time. It can produce small and flexible parts in an efficient way

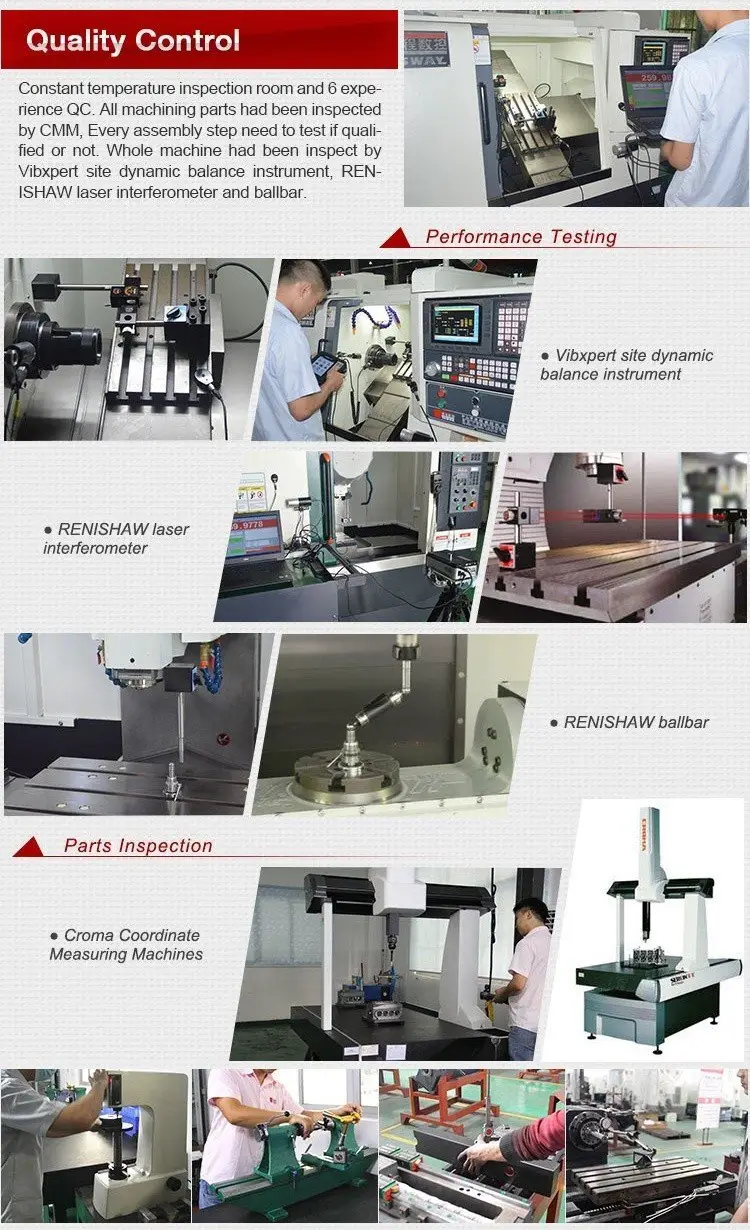

2. [企业简称] conducts standardized production in strict accordance with national standards and product technical requirements, and adopts scientific management methods to strictly supervise and control product quality to ensure that all turret lathe delivered to customers are high-quality and qualified products.

3. The product is stable in performance and long in service life. The base processed by gantry milling machine makes the product be of long service life

4. The quality of the product is guaranteed as quality is always crucial to the long-term development of our company. The product has been exported to many oversea countries, like UK

2-axis turret and tailstock CNC lathe machine holds multiple cutting tools, allowing for quick and automatic tool changes during machining operations. The turret can be indexed to position different tools in the cutting position, enabling the machine to perform various turning, facing, drilling, and threading operations without manual tool changes. | 2-axis turret and tailstock CNC lathe machine provides support to the workpiece during machining, ensuring stability and accuracy. The tailstock can be manually adjusted to accommodate different workpiece lengths and can also be used for drilling, boring, and other secondary operations. |

Advantage

2-axis turret and tailstock CNC lathe machine is a versatile machining solution that offers precise and efficient turning operations. Here are some of the advantages of this type of machine:

1. Simplicity and Ease of Use: A 2-axis turret and tailstock configuration simplifies the machining process, making it easier for operators to learn and operate the machine effectively.

2. Turning Operations: The machine's primary function is turning, which involves rotating the workpiece while using cutting tools to remove material and create desired shapes or profiles.

3. Turret Tooling: The turret on the machine holds multiple cutting tools, allowing for quick and automated tool changes. This enables efficient machining of complex parts without the need for manual tool changes, reducing downtime and increasing productivity.

4. Tailstock Support: The tailstock provides additional support to the workpiece during machining, ensuring stability and accuracy. It can also be used for drilling, boring, and other secondary operations.

5. Accuracy and Precision: The machine offers precise control over tool movements, resulting in high accuracy and quality surface finishes on machined components.

6. Cost-Effectiveness: Compared to machines with more complex configurations, a 2-axis turret and tailstock CNC lathe machine is typically more affordable, making it accessible to smaller businesses or those with specific machining requirements.

The 2-axis turret and tailstock CNC lathe machine combines simplicity, versatility, and precision to deliver efficient turning operations. Whether you need to produce simple or complex components, this machine offers a cost-effective and reliable solution for your machining needs.

580mm 2 axis cnc metal lathe machine

specification of 8/12 station tool turret,hydraulic tailstock

| Feature of 2 axis cnc lathe machine with turret CL46DW | ||

| 1.CNC machine with tailstock. Tailstock can be push in/out under hydraulic or pneumatic mode. | ||

| 2.Using Taiwan Swift .hydraulic turrent with 8 positions or 12 positions. | ||

| 3.Max. travel of Z-axis reaching 580 mm, can make high finish surface for long working-piece | ||

| 4.Z-axis with lead screw of Φ40mm, powerful and high speed. | ||

| 5.This machine is widely used in the flashlight, printer shaft, the motor shaft and so on processing industry. | ||

| 6.Machining precision up to 0.01mm | ||

| Technical parameter of 2 axis cnc lathe machine CL46DW | ||

| NC | TAIWAN/ CHINA | LNC/SYNTEC/GSK |

| Spindle | TaiWan Posa | A2-5/46 spindle |

| Hydraulic turret | Taiwan Swift | 8 positions or 12positions |

| X/Z axis servo motor | Japan YASKAWA | 1300 W |

| Spindle motor/servo motor | Shang hai Senlima | 7.5kw |

| Frequency converter | Magmeet | 11kw |

| Lead screw / lead rail | TaiWan Hiwin,PMI | C3, level two |

| Bearing | Japan NSK,Germany FAG | level 4 |

| Lead screw coupler | from Germany | precision |

| Parameters | ||

| CL46DW | ||

| Capacity | Spindle bore | ¢56 mm |

| Max. material diameter | ¢45 mm | |

| Max. machining diameter | ¢350 mm | |

| Max. lenght of machining | 550 mm | |

| Max. travel of x-axis | 460 mm | |

| Max. travel of z-axis | 580 mm | |

| Rapid speed (x-axis/z-axis) | 30 m/min | |

| Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | |

| Motor | Spindle variable frequency motor | 4KW/5.5KW |

| Max spindle speed | 4500 rpm | |

| X-axis servo motor | 1300 W | |

| Z-axis servo motor | 1300 W | |

| Tools | 25*25 | 8-12 |

| Tailstock | Tailstock travel | 580 mm |

| Thimble taper | MT4 | |

| Diameter of tailstock | ¢72 mm | |

| Other | Total power | 13 KW |

| Size(mm x mm x mm) | 2500×1500×1950 | |

| N.W. | 3800 KGS | |

Our Service

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in

front in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy

the long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements

of guests.

Welcome to contact us if need any more information.

Company Features

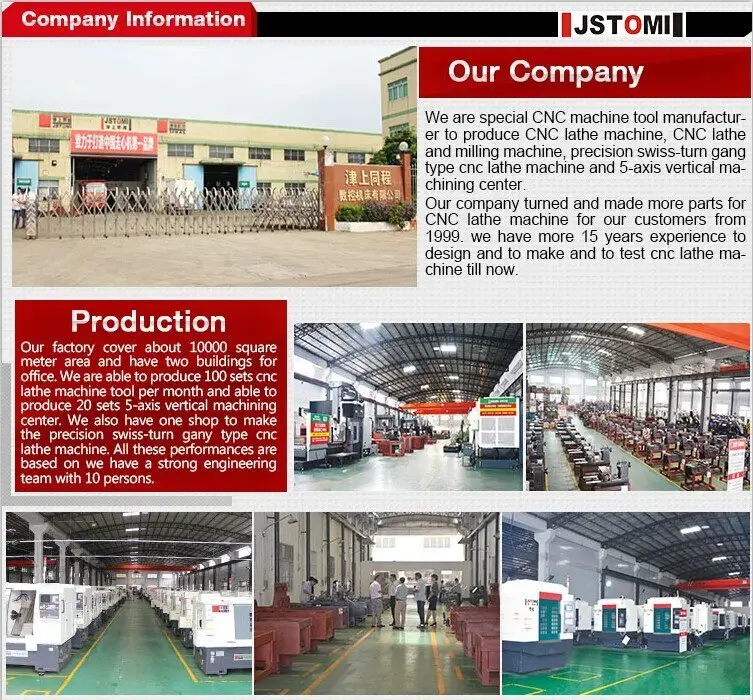

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has been very well-known in turret lathe industry. With Zhongshan JSTOMI CNC Machine Tool Co., Ltd. 's strong strength in science and technology, it benefits for the development of small cnc mill .

2. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has obtained ISO14001 environmental management system .

3. In this competitive society, it is necessary for Zhongshan JSTOMI CNC Machine Tool Co., Ltd. to introduce advanced technology. We are committed to being the most suitable supplier for customers. We will spare no effort to improve ourself, always keep pace with customers' requirements, and provide customers with professional services.