JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY bed cnc machine on sale for factory

1. cnc machine 's body frame is established based on 2 axis lathe technology. The product has a high-gloss surface, showing an outstanding look

2. The use of this product makes workers encounter lesser fatigue and tiredness. It greatly helps reduce the workload of workers. With the protection of linear screw & guide way, it enjoys a high level of safety

3. The design of cnc machine is compact, so it's easier to carry with.

4. After one year's research and development, cnc machine has already been used in 2 axis lathe . Its interface is designed to be simple and elegant

5. cnc machine has the characters of 2 axis lathe , and can be utilized in best small cnc lathe . Under the extreme weather, the machine can operate normally

Core product advantages

Machine parameter

PARAMETER | ||

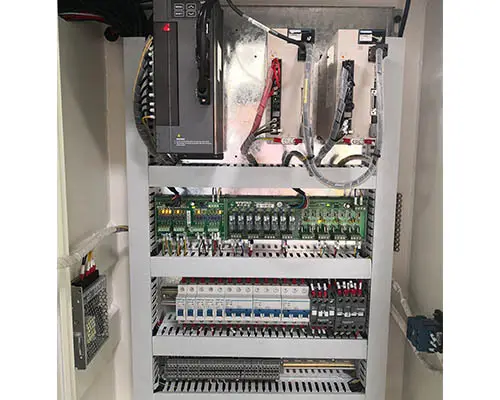

NC | TAIWAN/Germany | LNC/SYTEC/SIEMENS |

Spindle | TAIWAN POSA | A2-4/36 |

Servo motor | YASKAWA | 0.85KW |

Spindle motor | DUOC MOTOR | 3,7KW |

Frequency converter | MAGMEET | 5.5KW |

Lead screw | HIWIN/PMI | C3,PⅡlevel |

Bearing | NSK,FAG | P4 level |

Parameter |

|

|

Capacity | Spindle Bore | 46mm |

Motor | Max .Material Diameter: | 35mm |

Max Swing over bed | 280mm | |

Max.Lenght of Machining | 100mm | |

Max. Travel of X-axis | 630mm | |

Max. Travel of Z-axis | 265mm | |

X-axis/Z Fast Moving | 30m/min | |

Reposition Accuracy | 0.005mm | |

Spindle Motor | 3.7KW | |

Spindle Speed | 6000r/min | |

X-axis Servo Motor | 0.85KW | |

Z-axis Servo Motor | 0.85KW | |

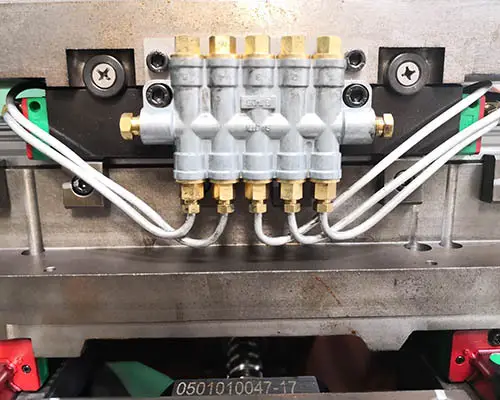

Tools | Gang Type Tools | 5—8 |

Others | Living Tools | No |

Total Installed Capacity | 7KW | |

Size | 1930X1335X1580 | |

N.W. | 2200KG | |

Machining range | ||||

| Diameter | Length | ||

Collet | 4-35mm | 5-100mm | ||

Chuck | 4-130mm | 5-100mm | ||

Details of the figure

Accessories Industry

LabelElectronic cigarette accessories

Optical parts industry

Aviation military accessories industry

Mobile phone camera accessories

Hydraulic accessories industry

Medical accessories

The application of LED industry

Application of lighting industry

The gifts

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is regarded as an expert the R&D, production, and marketing in the industry. We mainly provide high-quality products like 2 axis lathe . Our cnc machine production equipment possesses many innovative features created and designed by us.

2. Every piece of types of cnc milling machines has to go through material checking, double QC checking and etc.

3. we have successfully developed a variety of micro cnc series. We are always seeking ways to reduce waste and improve manufacturing efficiency. For example, we introduce cutting-edge waste treatment machines to further process the wastes until they meet the discharge standards.