JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

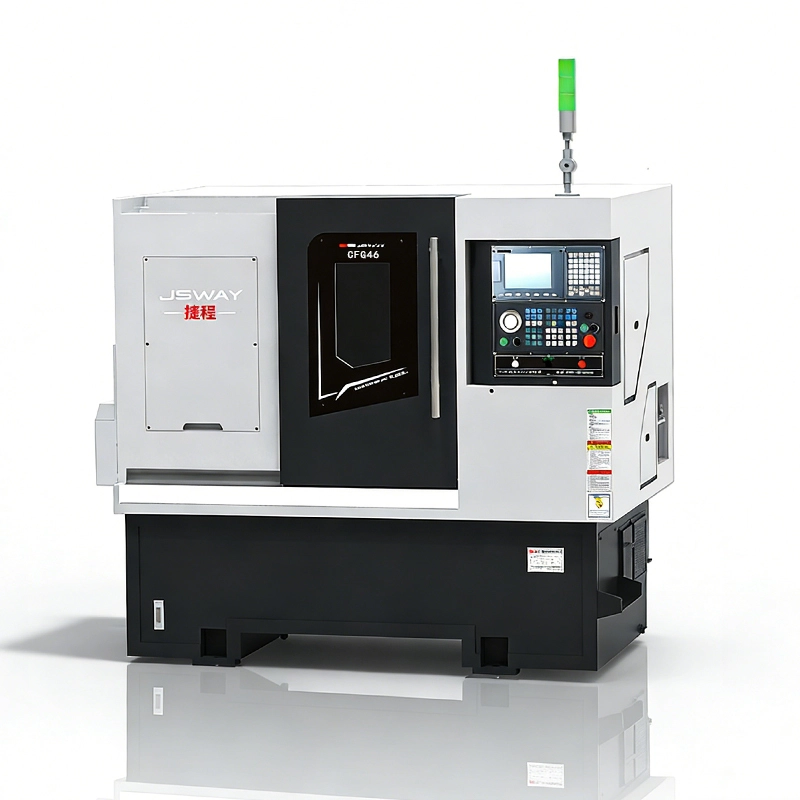

2 Axis Lathe CFG46D/CFG56D Slant Bed Turret CNC Lathe

A 2-axis CNC lathe is the most basic configuration, featuring only the X and Z axes. It is suitable for simple turning operations. It can perform basic turning operations such as turning diameters, facing, drilling, and threading. This configuration is ideal for mass production of simple-shaped parts, such as screws, nuts, and simple shaft parts.

All our CNC lathe models come with this 2-axis basic configuration, offering a solid foundation for a wide range of turning applications while maintaining simplicity and efficiency in operation.

Manufacturing requires a great deal of precision and detail when it comes to getting items exactly how they were planned. An industry that has taken precision to another level is CNC control and machining. When the machines are able to do the work without needing any kind of human intervention productivity increases and the best results are ensured for all of the items being produced.

The 2 axis control machine is an ideal solution for small and medium-scale precision manufacturing. It can be used in a variety of industries, including automotive, aerospace, medical, electronics, to create complex shapes with high accuracy. This type of machine will provide you with the ability to make precise cuts on any material that you choose. You can use it to produce components such as gears, bearings, and even complex assemblies like engines and more. The two-axis CNC lathe allows you to easily set up your own shop and start making parts right away.

The Advantages of a 2 Axis CNC Machine

There are many advantages to having a CNC 2 axis machine in your workshop. Some of these advantages include:

1. Increased accuracy and precision in manufacturing

A 2 axis lathe increases accuracy and precision in manufacturing by allowing for more precise control over the positioning of the tool in relation to the workpiece. This leads to a more consistent manufacturing process, with reduced variability in the final product. Additionally, a two-axis CNC machine can be used to produce more complex shapes and features than a traditional manual lathe or mill, making it a more versatile tool for manufacturing.

2. Reduced time to make complex parts

This type of CNC machine tools can quickly produce complex parts that would be difficult or impossible to create with traditional methods. This can save time and money, and improve productivity.

3. Increased repeatability of finished parts

A 2 axis CNC machine offers increased repeatability of finished parts due to the two linear axes of motion. This results in parts that are more consistent in terms of size and shape, which can be important for applications that require precise measurements.

4. Increased range of materials that can be cut

This is because they can move the cutting tool in two directions. This means that 2 axis machines can cut more complex shapes and are better suited for tasks such as engraving.

5. Faster removal of waste parts

A CNC two-axis machine tool can quickly remove waste parts from a workpiece, which can speed up the manufacturing process.

The Costs of Owning and Operating a 2 Axis CNC Lathe

The cost of owning and operating a two-axis CNC machine can vary depending on the type of machine you choose, its size, its features, and the location in which it will be used and stored. Generally, the cost of owning and operating this type of CNC lathe will range from $1,000 to $10,000 per year.

|

PARAMETER |

|||

|

|

|

CZG46D |

CZG56D |

|

CAPACITY |

Spindle bore |

56MM |

66 MM |

|

Max. material diameter: |

45MM |

52 MM |

|

|

Max swing over bed |

350MM |

350mm |

|

|

Max.lenght of machining |

100MM |

100 mm |

|

|

Max. travel of X-axis |

720MM |

720 mm |

|

|

Max. travel of Z-axis |

280MM |

280 mm |

|

|

X-axis/Z fast moving |

30 M/MIN |

30 m/min |

|

|

MOTOR |

Servo motor |

7.5KW |

7.5KW |

|

Spindle speed |

4500R/MIN |

3000 rpm/min |

|

|

X-axis servo motor |

1.3KW |

1.3KW |

|

|

Z-axis servo motor |

1.3KW |

1.3KW |

|

|

TOOLS |

Turret |

8+3 |

8+3 |

|

OTHERS

|

Size |

2025X1385X1910 |

2025X1385X1910 |

|

N.W. |

2700KG |

2750KG |

|

|

MACHINING RANGE |

||||

|

|

Diameter |

Length |

||

|

CZG46D |

CZG56D |

CZG46D |

CZG56D |

|

|

COLLET |

4-45mm |

4-52 |

5-100mm |

5-80mm |

|

CHUCK |

4-140mm |

4-160mm |

5-100mm |

5-80mm |