JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

en cnc turning lathe cost benefit for workshop JSWAY

1. JSWAY cnc lathe for sale is manufactured through superior manufacturing processes.

2. cnc turning lathe has the merit of cnc lathe for sale as compared with other similar products.

3. This kind of product can improve the working efficiency of work staff. The operation process is very simple and convenient.

4. This streamlined product helps reduce the environmental footprint. It can reduce scrap, use less energy, and help manufacturers save real money.

Core product advantages

Machine parameter

PARAMETER | ||

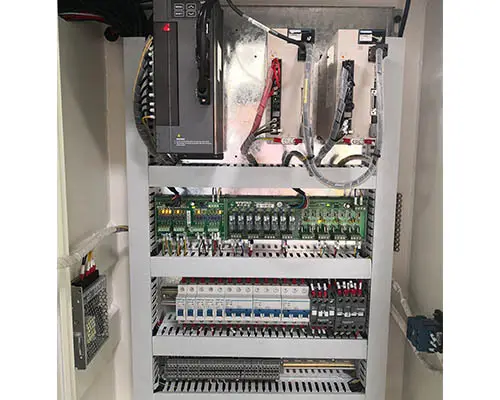

NC | TAIWAN/Germany | LNC/SYTEC/SIEMENS |

Spindle | TAIWAN POSA | A2-4/36 |

Servo motor | YASKAWA | 0.85KW |

Spindle motor | DUOC MOTOR | 3,7KW |

Frequency converter | MAGMEET | 5.5KW |

Lead screw | HIWIN/PMI | C3,PⅡlevel |

Bearing | NSK,FAG | P4 level |

Parameter |

|

|

Capacity | Spindle Bore | 46mm |

Motor | Max .Material Diameter: | 35mm |

Max Swing over bed | 280mm | |

Max.Lenght of Machining | 100mm | |

Max. Travel of X-axis | 630mm | |

Max. Travel of Z-axis | 265mm | |

X-axis/Z Fast Moving | 30m/min | |

Reposition Accuracy | 0.005mm | |

Spindle Motor | 3.7KW | |

Spindle Speed | 6000r/min | |

X-axis Servo Motor | 0.85KW | |

Z-axis Servo Motor | 0.85KW | |

Tools | Gang Type Tools | 5—8 |

Others | Living Tools | No |

Total Installed Capacity | 7KW | |

Size | 1930X1335X1580 | |

N.W. | 2200KG | |

Machining range | ||||

| Diameter | Length | ||

Collet | 4-35mm | 5-100mm | ||

Chuck | 4-130mm | 5-100mm | ||

Details of the figure

Accessories Industry

LabelElectronic cigarette accessories

Optical parts industry

Aviation military accessories industry

Mobile phone camera accessories

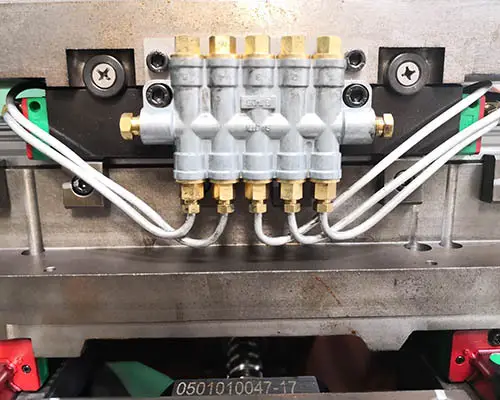

Hydraulic accessories industry

Medical accessories

The application of LED industry

Application of lighting industry

The gifts

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is a technologically advanced enterprise which mainly produces cnc turning lathe .

2. We keep growing and developing strong relationships with businesses around the world. Through the process of getting a product to market was becoming more complex, opportunities for achieving greater efficiencies with international vendors started to emerge.

3. To implement sustainability, we constantly seek new and innovative solutions to minimize the ecological impact of our products and processes during production. We consider the sustainability aspect of our processes very important. We constantly review our production process to maximize our positive impacts on the environment. Our company plays an active role in protecting natural resources and reducing environmental impact. We understand the impact that our factory may have on the environment, including changes in water quality and climate change. This is why we have long set environmental goals and share progress on a regular basis. Achieving sustainable development plans becomes vital in our business growth. We are looking for cleaner materials and create sustainable alternatives to the current packaging materials.