What about the supply capacity of twin spindle cnc lathe in JSWAY CNC Machine?

The supply capacity of twin spindle cnc lathe has been largely increased with time passing by. The supply capacity is a measure of efficiency such that we can adjust our production method according to the requirements of customers. To enhance our supply capacity, we have done a lot of efforts in many aspects. Firstly, we've hired enough skilled and experienced staff including designers, R&D technicians, and QC professionals making sure every production step is conducted smoothly. Secondly, we also keep checking, optimizing and updating machines so as to improve production efficiency. Moreover, Warehousing/storage capacity needs extreme attention as well.

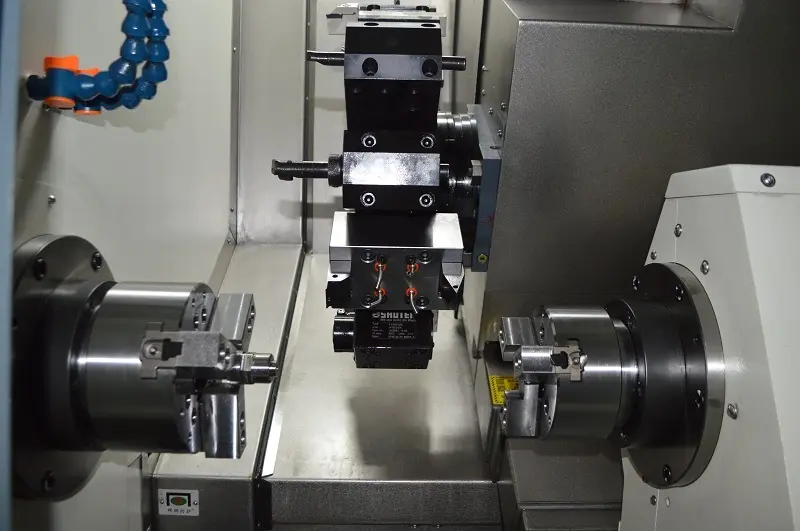

Years of experience has made Zhongshan JSTOMI CNC Machine Tool Co., Ltd. a competitive manufacturer and suppliers of cnc machining center. We enjoy a good reputation in the industry. The CNC lathe accessory series is widely praised by customers. JSWAY twin spindle cnc lathe is manufactured with high-performance materials. Due to the applications where the product is used, only those materials with desirable combinations of mechanical characteristics are selected. The product makes no noise during the operation. The product is durable in use. It has been tested under various conditions during production, including high and low temperatures, shock and vibrations, and salt spray. The product has been exported to many oversea countries, like UK.

JSWAY CNC Machine will expand the market with the most reliable products with star standards. Get more info!

All technical leaders and senior craftsmen from the company gathered, setting aside daily routines to focus intensely on the products themselves, such as Swiss-type lathes and turning-milling composite machines. Under the theme of "Challenge the Status Quo, Optimize the Design," the seminar facilitated candid and in-depth analysis, along with vigorous debate. The discussions focused on common issues and potential improvement points across the existing CNC machine tool product lines, specifically addressing reliability, usability, maintainability, and performance limits.

Fulfilling Customer Processing Requirements

JSWAY recognizes that machine tools must deliver value to customers. Its Swiss-type lathes efficiently handle small, complex components for industries like medical and electronics. The turn-mill machining centers, with their integrated multi-functional capabilities, enhance efficiency and quality in sectors such as automotive and mold manufacturing. These machines, designed to meet specific industry needs, bring new vitality to customers' production lines, helping them stay competitive and strengthening customer relationships in the era of intelligent manufacturing. As a Chinese machine tool manufacturer, JSWAY CNC COMPANY is customer-centric. It is dedicated to creating high-quality machine tools and providing superior equipment and services to boost industrial development and manufacturing progress. JSWAY CNC COMPANY — your reliable partner in CNC machining!

Tel: 0086-760-22185850

Contact Person: Mr. Xiang

E-mail: sales@jswaymachinetool.com 13326901601@163.com