vertical machining center export destinations

As more and more manufacturers continue to tap the potentials of vertical machining center , customers from different countries realize the value of the products and benefit from them a lot. Featuring supreme reliability, unique design style, and long-term service life, the products have become popular across the whole world and thereby, attracting more people in different industries from countries to devote to the sales business of the products. Also, with the implementation of China's reform and opening up to the outside world, the export business of the product is also booming.

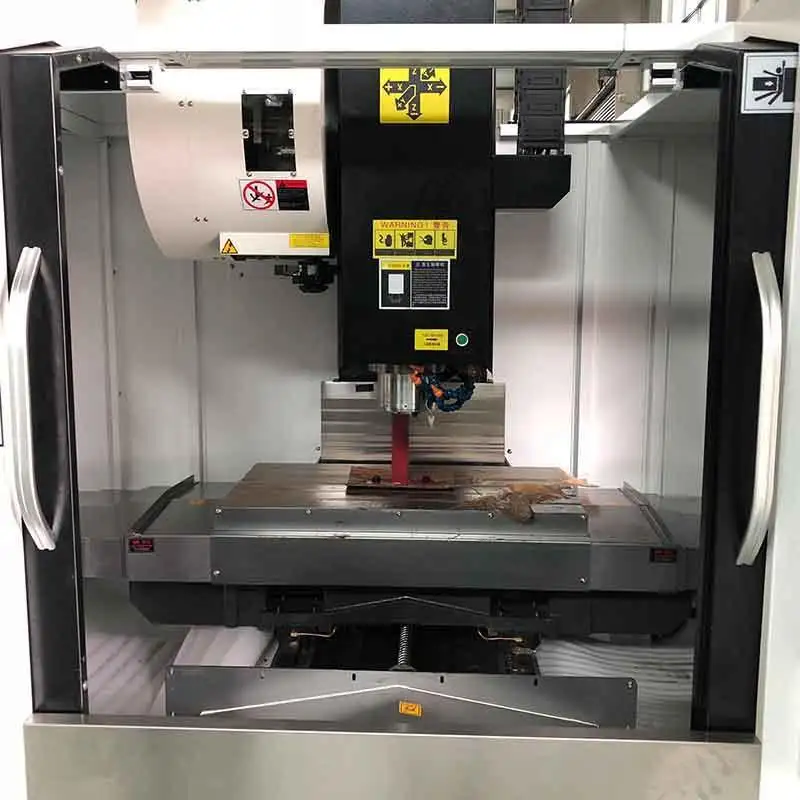

Specializing in the manufacture of cnc lathe machine for so many years, Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has gained an important presence in the market. The cnc turning center series has become a hot product of JSWAY CNC Machine. JSWAY swiss lathe features novel designs and diversified styles. The product is produced with a superior dynamic function. It has good thermal insulation properties. Factors like thickness and fiber density are designed in such a way as to contribute to the clothing insulation. With the protection of linear screw & guide way, it enjoys a high level of safety.

We aim to be an active and responsible leader committed to the sustainable development of global markets and promoting responsible practices in our industry.

All technical leaders and senior craftsmen from the company gathered, setting aside daily routines to focus intensely on the products themselves, such as Swiss-type lathes and turning-milling composite machines. Under the theme of "Challenge the Status Quo, Optimize the Design," the seminar facilitated candid and in-depth analysis, along with vigorous debate. The discussions focused on common issues and potential improvement points across the existing CNC machine tool product lines, specifically addressing reliability, usability, maintainability, and performance limits.

Fulfilling Customer Processing Requirements

JSWAY recognizes that machine tools must deliver value to customers. Its Swiss-type lathes efficiently handle small, complex components for industries like medical and electronics. The turn-mill machining centers, with their integrated multi-functional capabilities, enhance efficiency and quality in sectors such as automotive and mold manufacturing. These machines, designed to meet specific industry needs, bring new vitality to customers' production lines, helping them stay competitive and strengthening customer relationships in the era of intelligent manufacturing. As a Chinese machine tool manufacturer, JSWAY CNC COMPANY is customer-centric. It is dedicated to creating high-quality machine tools and providing superior equipment and services to boost industrial development and manufacturing progress. JSWAY CNC COMPANY — your reliable partner in CNC machining!

Tel: 0086-760-22185850

Contact Person: Mr. Xiang

E-mail: sales@jswaymachinetool.com 13326901601@163.com