Quality assurance of twin spindle cnc lathe

Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is always engaged in the process of quality assurance (QA) as a means to ensure a high level of quality in production during the development of products. Managing the quality of production involves many detailed steps of planning, fulfilling, monitoring activities. Firstly, we will plan and establish the process related objectives and determine the processes that are required to deliver high-quality end products. Then, the process of development and testing begins. Lastly, professionals will be responsible for monitoring and modifying the processes and checking whether the product meets the standard requirements. With years of development, we have got certifications of ISO, an organization who maintains an effective quality assurance system for manufacturing and service industries.

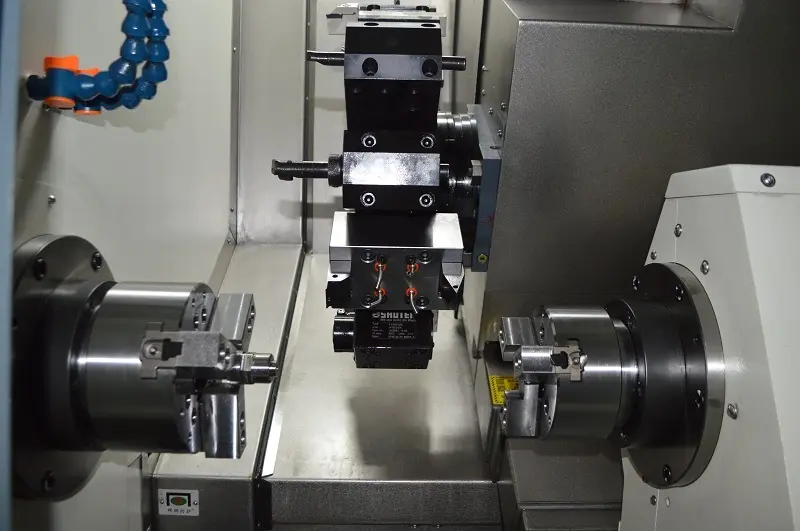

JSWAY CNC Machine is a competitive manufacturer of cnc lathe machine, who stands out among thousands of manufacturers in China. We have been supplying qualified cnc lathe machine. The cnc lathe series is widely praised by customers. The manufacture of JSWAY swiss lathe is of professionalism. The process mainly includes the following stages: the procurement of metal materials, fabrication of the frame, machining and assembly of component parts, and commissioning. Before being shipped out, it will be tested and operated in process to guarantee its zero defects. The product features high efficiency. It is able to perform tasks at a high speed and is capable of delivering results within short periods of time. Its axis runs very fast, which can guarantee the highly efficient automatic machining.

It is the experienced service of JSWAY that has attracted many customers. Get an offer!

All technical leaders and senior craftsmen from the company gathered, setting aside daily routines to focus intensely on the products themselves, such as Swiss-type lathes and turning-milling composite machines. Under the theme of "Challenge the Status Quo, Optimize the Design," the seminar facilitated candid and in-depth analysis, along with vigorous debate. The discussions focused on common issues and potential improvement points across the existing CNC machine tool product lines, specifically addressing reliability, usability, maintainability, and performance limits.

Fulfilling Customer Processing Requirements

JSWAY recognizes that machine tools must deliver value to customers. Its Swiss-type lathes efficiently handle small, complex components for industries like medical and electronics. The turn-mill machining centers, with their integrated multi-functional capabilities, enhance efficiency and quality in sectors such as automotive and mold manufacturing. These machines, designed to meet specific industry needs, bring new vitality to customers' production lines, helping them stay competitive and strengthening customer relationships in the era of intelligent manufacturing. As a Chinese machine tool manufacturer, JSWAY CNC COMPANY is customer-centric. It is dedicated to creating high-quality machine tools and providing superior equipment and services to boost industrial development and manufacturing progress. JSWAY CNC COMPANY — your reliable partner in CNC machining!

Tel: 0086-760-22185850

Contact Person: Mr. Xiang

E-mail: sales@jswaymachinetool.com 13326901601@163.com