JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

precise turret lathe machine torno manufacturer for plant

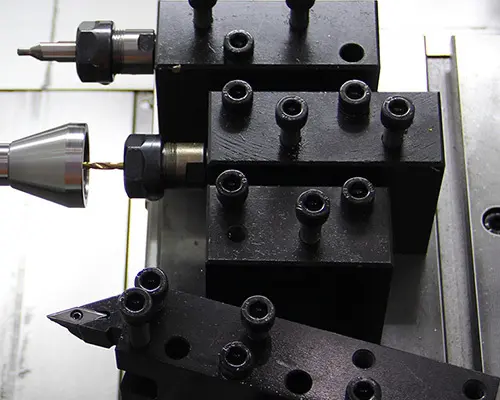

1. turret lathe machine is composed of capstan and turret lathe . It can produce small and flexible parts in an efficient way

2. This product would be a valuable asset for every investor because it is going to make any task an easy job. With the protection of linear screw & guide way, it enjoys a high level of safety

3. The product is sustainable. It is made of recyclable parts which are environmentally friendly and these parts can stand up many times of use. It can be provided with long-term technical support

4. The product is highly resistant to color fading. It is treated with a special technique to enhance its capacity on color retention. Its interface is designed to be simple and elegant

5. It has a suitable level of air permeability. Type of yarn, fabric structure, and fiber parameters all contribute to this property. It is very easy to maintain, offering more convenience

Core product advantages

Machine parameter

PARAMETER | |||

CAPACITY |

| M46 | M56 |

Spindle bore | 56MM | 66 MM | |

Max. material diameter | 45MM | 52 MM | |

Max swing over bed | 350MM | 350mm | |

Max.lenght of machining | 100MM | 100 mm | |

Max. travel of X-axis | 715MM | 715 mm | |

Max. travel of Z-axis | 280MM | 280 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

MOTOR | Servo motor | 5.5KW | 7.5KW |

Spindle speed | 4500R/MIN | 3000 rpm/min | |

X-axis servo motor | 0.85KW | 1.3KW | |

Z-axis servo motor | 0.85KW | 1.3KW | |

TOOLS | Gang type tools | 6-8 | 6-8 |

OTHERS | Total installed capacity | 9 KW | 13 KW |

Size | 2025X1385X1910 | 2025X1385X1910 | |

N.W. | 2700KG | 2750KG | |

MACHINING RANGE | ||||

COLLET | Diameter | Length | ||

CFG46 | CFG56 | CFG46 | CFG56 | |

4-45mm | 4-52 | 5-100mm | 5-80mm | |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-80mm |

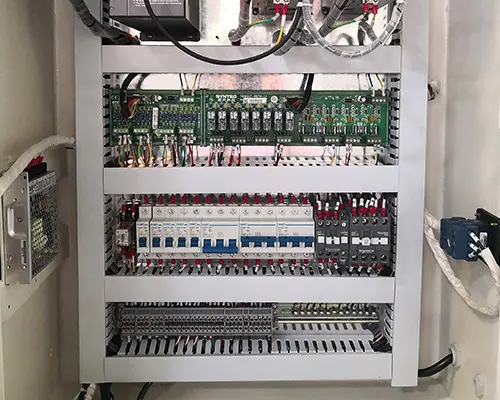

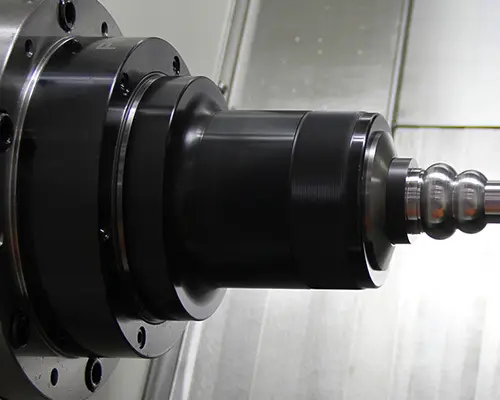

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. After years of engagement in manufacturing turret lathe machine, Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has been a well-positioned and reliable manufacturer with years of experience.

2. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has in-depth grasp of close concepts of high speed lathe .

3. We have a clear long-term strategy. We want to become more customer-focused, more innovative, and more agile in our internal processes and customer-facing activities.