JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

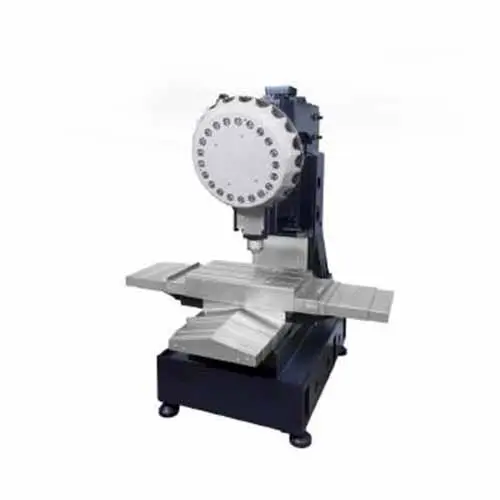

JSWAY security cnc machining center for sale for plant

- JSTOMI has established a complete service system to provide consumers with intimate after-sales services.

1. The designed of JSWAY cnc machining prototype service is sophisticated. It is developed by professionals who have been involved in the characterization, Mechanical design, and development of advanced technology products for years.

2. The product is energy efficient. When it is not in use, it will automatically turn off to help minimize power consumption.

3. In tune with the industry standard, these potential products meet the needs of our clients.

4. Our offered products are valued for their tremendous market potential.

Machine parameter

PARAMETER | ||||

| MODEL | UNIT | JD640 | JDT640 | |

CONTROLLER | NC | SET | MITSUBICHI E80 | MITSUBICHI M80/FANUC |

| TOTAL AXIS | AXIS | 3 | 3 | |

TABLE | TABLE SIZE | MM | 700*420 | 700*420 |

| TABLE LOAD | KG | 300 | 300 | |

| T-SLOT | MM | 3-14*125 | 3-14*125 | |

TRAVEL | X AXIS | MM | 600 | 600 |

| Y AXIS | MM | 400 | 400 | |

| Z AXIS | MM | 300 | 300 | |

SPINDLE | SPINDLE TAPPER | MM | BT30/Φ100 | BT30/Φ100 |

| MAX.SPINDLE SPEED | RPM/MIN | 24000/30000 | 15000/20000 | |

| SPINDLE DRIVEN TYPE | TYPE | electrical spindle | direct | |

| SPINDLE CENTER TO MACHINE SPINE | MM | 500 | 500 | |

| SPINDLE END FACE TO TABLE | MM | 150-450 | 150-450 | |

GUIDE RAIL | X/Y/Z AXIS BALL SCREW | MM | 2808/2808/3208 | 3216/3216/3216 |

| X/Y/Z AXIS GUIDE RAIL | linear guide rail | linear guide rail | ||

MOTOR | X/Y/Z AXIS MOTOR CONNECT TYPE | TYPE | direct | direct |

| SPINDLE MOTOR | KW | 5.5 | 5.5 | |

| X/Y/Z AXIS SERVO MOTOR | KW | 1.5/1.5/3.0 | 1.5/1.5/3.0 | |

| COOLANT PUMP MOTOR | W | 750W*2 | 750W*2 | |

FEEDING RATE | X/Y/Z WORKING RATE | M/MIN | 10/10/10 | 10/10/10 |

| X/Y/Z RAPID SPEED | M/MIN | 24/24/24 | 60/60/48 | |

POWER/AIR PRESSURE | AIR PRESSURE | KG/CM² | 6kg/cm² | 6kg/cm² |

| POWER SUPPLY | kva | 15kva | 15kva | |

ACCURACY | POSITIONING ACCURACY | MM | ±0.003/300 | ±0.005/300 |

| REPOSITIONING ACCURACY | MM | ±0.003/300 | ±0.005/300 | |

SPEC | NET WEIGHT | T | 3.2 | 3.2 |

| DEMENSION | MM | 2000*2000*2100 | 2000*2000*2100 | |

Standard Accessory

◪Water tank and chips filter

◪Auto lubrication system

◪File transfer software and cable

◪Spindle oil cooler

◪Hand wheel

◪Transformer

◪3 color warning lamp

◪Tool box

◪Full cover

◪Anchor bolt

◪Double working lamp

◪Turret(16tools)

◪Air blow gun

◪Tool box

◪Manual

◪Cabinet heat exchange

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is an ever-growing Chinese company that specializes in designing and manufacturing cnc machining prototype service . We are known for our expertise and experience.

2. JSWAY invested a lot of money in our technology introduction.

3. As a responsible manufacturing company, we take a close interest in environmental projects in the communities where we're based. We have taken a lead in encouraging people to recycle and choose reusable materials such as chopsticks and mugs. Our company bears social responsibilities. We are switching to 100 percent renewable energy by investing in utility-scale solar and wind projects. Our mission is to create value for the customer through trust, innovation, functionality, comprehensive designs, and technology-driven operations & manufacturing processes.

1. What is your minimum order quantity and warranty?

MOQ is one set, and warranty is one year.

2.What CNC system do you use?

FANUC, SIEMENS, MISTSUBISHI, GSK etc. It depends on your choice.

3.When is the delivery time?

We will delivery it within 90 days after received your payments

4. How to handle the warranty period?

During the warranty period, because of product quality problems, the company is responsible for free maintenance, if need to change parts, we be responsible for free replacement.

If the machine problem is not belonging to our machine quality problems, when the buyer needs us send engineers to give repairing service, we charge the appropriate cost.

5.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer’s installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD100.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.