JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY safe cnc vertical lathe machine with tailstock for plant

-

v s

1. JSWAY cnc vertical lathe machine incorporates different principles of fashion design. As only through the consistent use of all principles can a successful and eye-catching design be created.

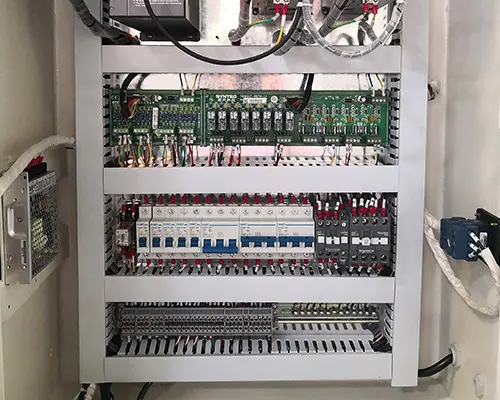

2. The product is impervious to impact and vibration. It has a robust housing to house the electric parts, so as to prevent the parts from the vibration during operation.

3. It can effectively clean out all small, medium, large debris, or even particles or bacteria which are invisible to the naked eye if used together with different cleaning tools.

4. The product is now widely available in a wide range of industries and has a wide range of applications.

5. The product has a large assortment of applications it is suitable for.

Core product advantages

Machine parameter

PARAMETER | |||

CAPACITY |

| M46 | M56 |

Spindle bore | 56MM | 66 MM | |

Max. material diameter | 45MM | 52 MM | |

Max swing over bed | 350MM | 350mm | |

Max.lenght of machining | 100MM | 100 mm | |

Max. travel of X-axis | 715MM | 715 mm | |

Max. travel of Z-axis | 280MM | 280 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

MOTOR | Servo motor | 5.5KW | 7.5KW |

Spindle speed | 4500R/MIN | 3000 rpm/min | |

X-axis servo motor | 0.85KW | 1.3KW | |

Z-axis servo motor | 0.85KW | 1.3KW | |

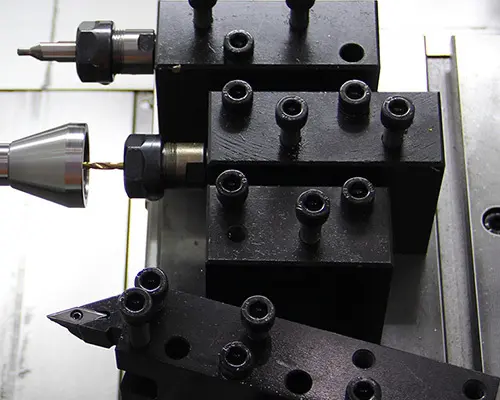

TOOLS | Gang type tools | 6-8 | 6-8 |

OTHERS | Total installed capacity | 9 KW | 13 KW |

Size | 2025X1385X1910 | 2025X1385X1910 | |

N.W. | 2700KG | 2750KG | |

MACHINING RANGE | ||||

COLLET | Diameter | Length | ||

CFG46 | CFG56 | CFG46 | CFG56 | |

4-45mm | 4-52 | 5-100mm | 5-80mm | |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-80mm |

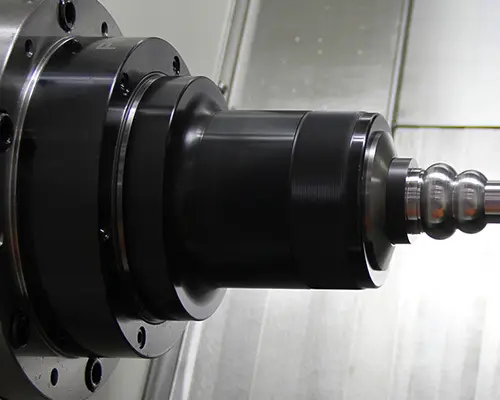

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. With so many years, Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has been concentrating on the design and manufacture of 2 axis lathe . We have gained extensive knowledge and expertise.

2. We have a perfect quality control system, and we have obtained the ISO 9001 international quality system certification. All of our production processes will comply with the regulations stipulated in this system.

3. We are committed to maintaining the highest ethical standards in our business. We have implemented an integrity management plan that sets out the administrative structure and measures for integrity management. Ask! Our goal is to provide consistent customer delight. We are putting efforts on providing innovative products at the highest level. Sustainable development is at the core of our daily work and guides our future progress. We believe we will benefit from these efforts in many ways. Ask! Our company bears social responsibility. We strive to minimize waste generation through a dozen waste reduction initiatives. Many of our production lines have achieved 0 waste generation.