JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY precise machine tool factory for workshop

1. The design of JSWAY is scientific. It is the application of mathematics, kinematics, mechanics of materials, mechanical technology of metals, etc. Each accessory of the product is self-made, ensuring its machining precision

2. By adopting advanced technology, the quality of machine tool can be assured. The product is produced with a superior dynamic function

3. The product is of top quality and has reliable performance at competitive prices. Before being shipped out, it will be tested and operated in process to guarantee its zero defects

4. Our professional team ensures to offer the highest quality of this product. It can be offered at a favorable price

Core product advantages

Machine parameter

PARAMETER | ||

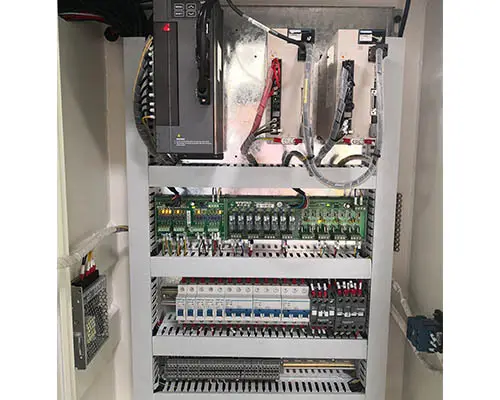

NC | TAIWAN/Germany | LNC/SYTEC/SIEMENS |

Spindle | TAIWAN POSA | A2-4/36 |

Servo motor | YASKAWA | 0.85KW |

Spindle motor | DUOC MOTOR | 3,7KW |

Frequency converter | MAGMEET | 5.5KW |

Lead screw | HIWIN/PMI | C3,PⅡlevel |

Bearing | NSK,FAG | P4 level |

Parameter |

|

|

Capacity | Spindle Bore | 46mm |

Motor | Max .Material Diameter: | 35mm |

Max Swing over bed | 280mm | |

Max.Lenght of Machining | 100mm | |

Max. Travel of X-axis | 630mm | |

Max. Travel of Z-axis | 265mm | |

X-axis/Z Fast Moving | 30m/min | |

Reposition Accuracy | 0.005mm | |

Spindle Motor | 3.7KW | |

Spindle Speed | 6000r/min | |

X-axis Servo Motor | 0.85KW | |

Z-axis Servo Motor | 0.85KW | |

Tools | Gang Type Tools | 5—8 |

Others | Living Tools | No |

Total Installed Capacity | 7KW | |

Size | 1930X1335X1580 | |

N.W. | 2200KG | |

Machining range | ||||

| Diameter | Length | ||

Collet | 4-35mm | 5-100mm | ||

Chuck | 4-130mm | 5-100mm | ||

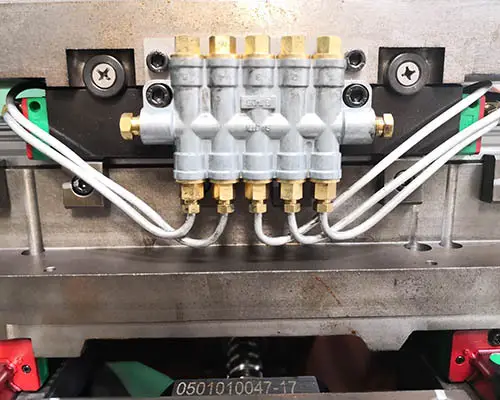

Details of the figure

Accessories Industry

LabelElectronic cigarette accessories

Optical parts industry

Aviation military accessories industry

Mobile phone camera accessories

Hydraulic accessories industry

Medical accessories

The application of LED industry

Application of lighting industry

The gifts

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. JSWAY has innovative equipment to manufacture high-quality machine tool . By establishing a high-tech laboratory, JSWAY has enough capacity to create milling machine tools .

2. The production technology has been constantly optimized by JSWAY.

3. In order to improve market competitiveness, JSWAY is mainly invested in optimizing technology production of cnc turning center . We have been cooperating with our staff to produce the high quality cnc china machine to exceed the expectation of the customers. Inquire now!