JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY precise high speed lathe manufacturer for workshop1

1. The production JSWAY slant bed cnc lathe machine is efficient enough to meet your manufacturing needs, no matter the scale of production.

2. The product is stringently tested before being made available in the market and is widely accepted among global customers.

3. JSTOMI CNC Machine has established long-term and stable cooperation with many competitive brands.

4. Through the strict test upon high speed lathe , the quality of it can be guaranteed.

Core product advantages

Machine parameter

PARAMETER | |||

|

| CFG46D | CFG56D |

CAPACITY | Spindle bore | 56MM | 66 MM |

Max. material diameter: | 45MM | 52 MM | |

Max swing over bed | 350MM | 350mm | |

Max.lenght of machining | 100MM | 100 mm | |

Max. travel of X-axis | 715MM | 715 mm | |

Max. travel of Z-axis | 280MM | 280 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

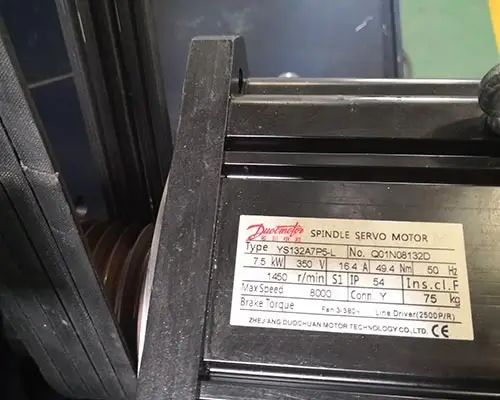

MOTOR | Servo motor | 5.5KW | 7.5KW |

Spindle speed | 4500R/MIN | 3000 rpm/min | |

X-axis servo motor | 0.85KW | 1.3KW | |

Z-axis servo motor | 0.85KW | 1.3KW | |

TOOLS | Gang type tools | 6-8 | 6-8 |

OTHERS | Total installed capacity | 9 KW | 13 KW |

Size | 2025X1385X1910 | 2025X1385X1910 | |

N.W. | 2700KG | 2750KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CFG46 | CFG56 | CFG46 | CFG56 | |

COLLET | 4-45mm | 4-52 | 5-100mm | 5-80mm |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-80mm |

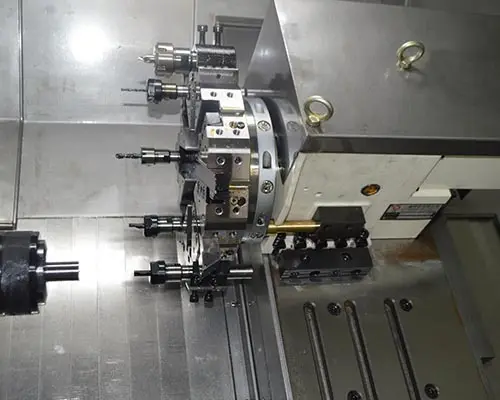

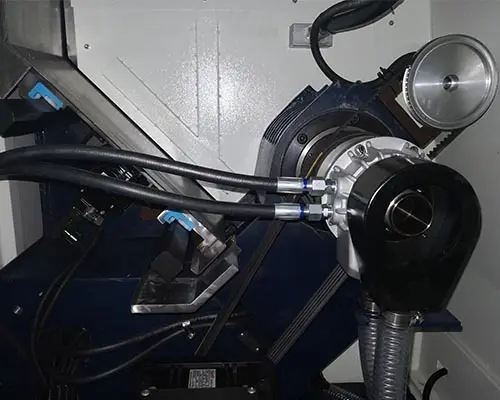

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. The sales volume of high speed lathe from Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is steadily increased year by year.

2. JSWAY provides new, competitive precision lathe to meet customer needs.

3. We will continue to improve the quality of service rendered by each employee from Zhongshan JSTOMI CNC Machine Tool Co., Ltd. . Call! We make customers more aware and confident in their turret lathe machine projects. Call! JSWAY firmly believes that we will become a world-renowned speaker of slant bed cnc lathe machine . Call!