Is 4 axis cnc turning machine tested before shipment?

Yes. 4 axis cnc turning machine will be tested before being delivered. Quality control tests are performed at various stages and the final quality test before shipping is primarily to ensure accuracy and ensure no defects prior to shipping. We've got a team of quality inspectors who are all familiar with the quality standard in the industry and pay great attention to every detail including product performance and package. Normally, one unit or piece will be tested and, it will not be shipped until it has passed the tests. Performing quality checks helps us in monitoring our products and processes. It also reduces the costs associated with shipping errors as well as the expenses that will be shouldered by both the customers and the company when processing any returns due to defective or inaccurately delivered products.

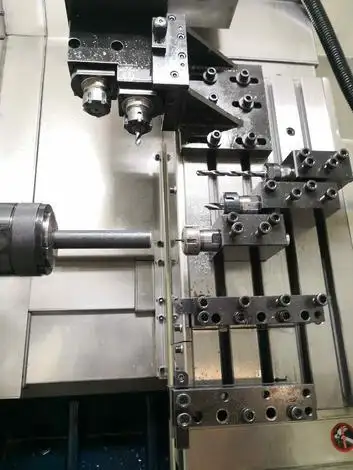

Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is a well-known domestic swiss lathe manufacturer. We have the expertise and experience to lead the market. slant bed cnc lathe series manufactured by JSWAY CNC Machine include multiple types. And the products shown below belong to this type. The reflector of CNC lathe accessory adopts optical gold-plating process, which has high reading efficiency, sensitive sensing, and accurate and fast scanning. Thoroughly tested designs and the latest materials, it solves the problems that plague users' sleep. Along with a healthy bed-time regimen, it will help users wake up refreshed and full of energy every morning. Made by the high technology, the product meets the high international standard.

Our commitment is to provide innovative products and services of the highest standards that surpass customer expectations of quality, delivery, and productivity.

All technical leaders and senior craftsmen from the company gathered, setting aside daily routines to focus intensely on the products themselves, such as Swiss-type lathes and turning-milling composite machines. Under the theme of "Challenge the Status Quo, Optimize the Design," the seminar facilitated candid and in-depth analysis, along with vigorous debate. The discussions focused on common issues and potential improvement points across the existing CNC machine tool product lines, specifically addressing reliability, usability, maintainability, and performance limits.

Fulfilling Customer Processing Requirements

JSWAY recognizes that machine tools must deliver value to customers. Its Swiss-type lathes efficiently handle small, complex components for industries like medical and electronics. The turn-mill machining centers, with their integrated multi-functional capabilities, enhance efficiency and quality in sectors such as automotive and mold manufacturing. These machines, designed to meet specific industry needs, bring new vitality to customers' production lines, helping them stay competitive and strengthening customer relationships in the era of intelligent manufacturing. As a Chinese machine tool manufacturer, JSWAY CNC COMPANY is customer-centric. It is dedicated to creating high-quality machine tools and providing superior equipment and services to boost industrial development and manufacturing progress. JSWAY CNC COMPANY — your reliable partner in CNC machining!

Tel: 0086-760-22185850

Contact Person: Mr. Xiang

E-mail: sales@jswaymachinetool.com 13326901601@163.com