How to pay for vertical machining center ?

Zhongshan JSTOMI CNC Machine Tool Co., Ltd. supports several types of payment methods, like open account, cash in advance, and L/C. There is no doubt that the payment method is one of the most important factors that buyers and sellers consider when negotiating a contract. This is because choosing the wrong payment could be detrimental to your business. An appropriate payment method can minimize the payment risk while also accommodating the needs of customers. Take one of the payment methods as an example, cash in advance is a type of payment where the buyer pays the seller upfront before the goods are shipped. Wire transfers and credit cards are the most frequently used payment options for this method. This method protects the seller from buyers who may not honor the terms of the contract and decide not to pay.

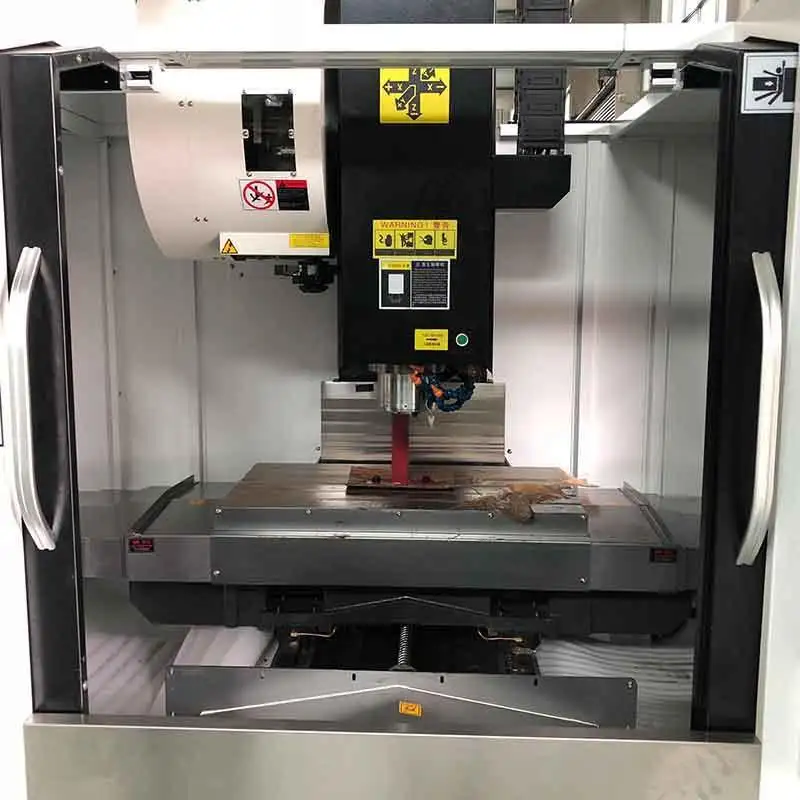

JSWAY CNC Machine has been an important market player of vertical machining center for years. We are renowned as an expert in R&D, design, and production. The cnc machining center series has become a hot product of JSWAY CNC Machine. When manufacturing JSWAY cnc turning center, we take the quality of raw materials into consideration. Its axis runs very fast, which can guarantee the highly efficient automatic machining. JSWAY CNC Machine is able to provide customers with the most suitable CNC lathe accessory products to meet your particular needs. Thanks to the craftsmanship, its size will not change once it is turned on again.

Focused on social responsibility, our company has developed and established a comprehensive set of sustainable business initiatives that improve our approach to operating the business.

All technical leaders and senior craftsmen from the company gathered, setting aside daily routines to focus intensely on the products themselves, such as Swiss-type lathes and turning-milling composite machines. Under the theme of "Challenge the Status Quo, Optimize the Design," the seminar facilitated candid and in-depth analysis, along with vigorous debate. The discussions focused on common issues and potential improvement points across the existing CNC machine tool product lines, specifically addressing reliability, usability, maintainability, and performance limits.

Fulfilling Customer Processing Requirements

JSWAY recognizes that machine tools must deliver value to customers. Its Swiss-type lathes efficiently handle small, complex components for industries like medical and electronics. The turn-mill machining centers, with their integrated multi-functional capabilities, enhance efficiency and quality in sectors such as automotive and mold manufacturing. These machines, designed to meet specific industry needs, bring new vitality to customers' production lines, helping them stay competitive and strengthening customer relationships in the era of intelligent manufacturing. As a Chinese machine tool manufacturer, JSWAY CNC COMPANY is customer-centric. It is dedicated to creating high-quality machine tools and providing superior equipment and services to boost industrial development and manufacturing progress. JSWAY CNC COMPANY — your reliable partner in CNC machining!

Tel: 0086-760-22185850

Contact Person: Mr. Xiang

E-mail: sales@jswaymachinetool.com 13326901601@163.com