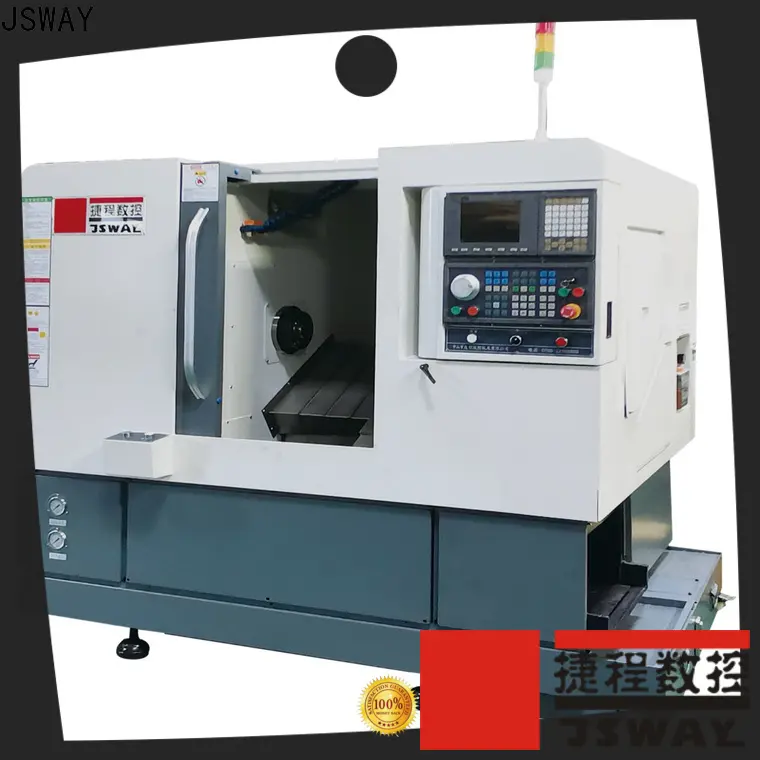

Gang tool 2-axis cnc machine is a specific type of cnc lathe or cnc turning center that utilizes a gang tooling system for machining operations. Gang tool 2-axis cnc machines are often cost-effective solutions for small to medium batch production of precision parts due to their efficient tooling system and high-speed machining capabilities.

2-Axis lathe

2-Axis slant bed lathe series combines proven machine design with advance technology in control and manufacturing. Reliability and stability make these a favorite among demanding job shops and in-house productions alike. The heavy duty turret and rigid machine body structure enable higher turning efficiency with better finish and longer tool life – resulting in greater productivity and profitability all around. Upgrade your global competitiveness today.

√ Up to 15″ 3-jaw chuck with 5.15″ bar capacity

√ Up to 35.4″ max turning diameter and 82″ max turning length

√ High speed / high accuracy 12 station turret

√ Induction hardened and precision ground box ways

√ 45° slant bed with one piece Meehanite® casting for superior dampening and stability

√ High grade C3 precision ball screws and pretension for enhanced precision

√ Auto lubrication system metered check valves and piston distributor

Features:

● 2 axis cnc machine adopts with mechanical, electricity, pneumatic trinity, according to ergonomic amenity layout design, fully enclosed protection, compact structure, saving area, easy operation, easy maintenance.

● The X/Z-axis installation process is very advanced, the processing speed is fast, the processing size is very accurate, and the hot and cold machine ruler hardly changes. The processing speed can reach up to 36 m/min, factory value is set to 30 m/min.

● Taiwan POSA/ROYAL vertical precision spindle, under precision dynamic balanced, and the bearings are lubricated with permanent imported grease, keep the spindle rotating smoothly at high speed and reduce thermal deformation to a minimum. High cutting speed up to 6000r/min, can be high-gloss processing.

● 2 axis cnc machine is connected with the servo motor and the lead screw directly for both vertical and horizontal directions, Japan NSK lead rod bearings to ensure the transmission high precision.

● 2 axis lathe With high-performance automatic intermittent lubrication system, which can lubricate the bed guide rail and X/Z lead rod in a timely manner to ensure the guide rail surface and vertical and horizontal lead rod are always in a good lubrication state.

● cnc lathe 2 axis With horizontal type tool holder , which the arrangement and adjustment are more convenient. Automatic pull-out material device can be installed on the tool holder and controlled by numerical control system easily realize the automation of on-line collaboration. To improve the production efficiency.

| Model No. | M36 |

| Machine type | Turning and milling machine |

| AXES | XZ |

| Operating system | LNC 5800 or

SYNTEC 22TA |

| Processing ability | Maximum bar diameter (MM) | 35 |

| Maximum rotation diameter (MM) | 280 |

| Maximum processing length (MM) | 100 |

| X-axis maximum travel (MM) | 810 |

| Y-axis maximum travel (MM) | N |

| Z-axis maximum stroke (MM) | 280 |

| X/Z axis fastest movement rate (M/ MIN) | 30 |

| Y-axis fastest movement rate (M/ MIN) | N |

| Center height(MM) | 60 |

| Precision | X-axis repeat positioning accuracy (MM) | 0.005 |

| Y-axis repeat positioning accuracy (MM) | N |

| Z-axis repeat positioning accuracy (MM) | 0.008 |

| Motor | Spindle motor (KW) | 3.7 |

| X-axis motor (KW) | 0.85 |

| Y-axis motor (KW) | N |

| Z-axis motor (KW) | 0.85 |

| Power head motor (KW) | N |

| Driver | Spindle drive(KW) | 5.5 |

| X-axis drive(KW) | 1.0 |

| Z-axis drive(KW) | 1.0 |

| Tools | quantity | 5-10 |

| Power tools | N |

| Others | Total machine power (approximate, KW) | 8.0 |

| Spindle: Taiwan Pusen | A2-4 |

| Cylinder: JSWAY customized (inch) | 5 |

| Size (approximate, MM) | 2200x1480x1750 |

| Weight (approximate, KG) | 2900 |

High precision, durable life, stable, high efficiency, simple operation, easy maintenance