JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

utility swiss type automatic lathe lathe manufacturer for factory

1. The production of JSWAY small swiss lathe is well-organized according to the lean production method. The product can be produced in large quantities in a short time

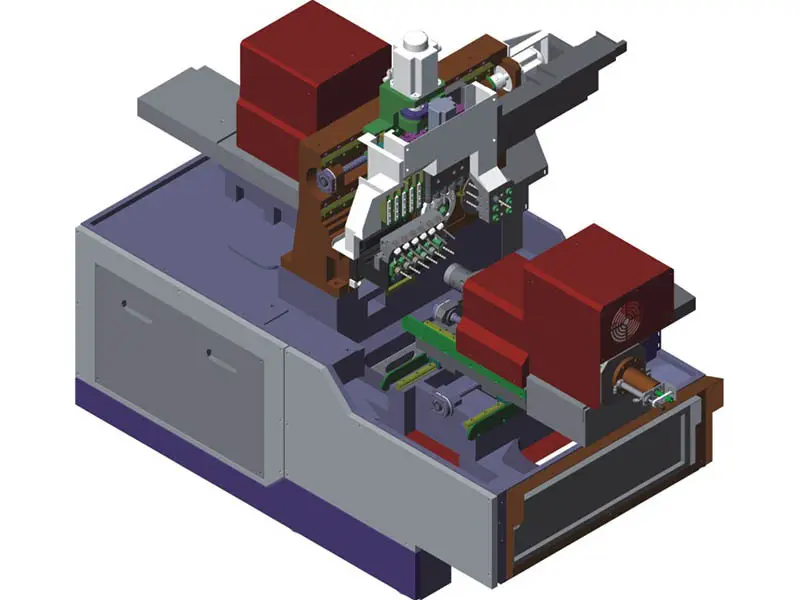

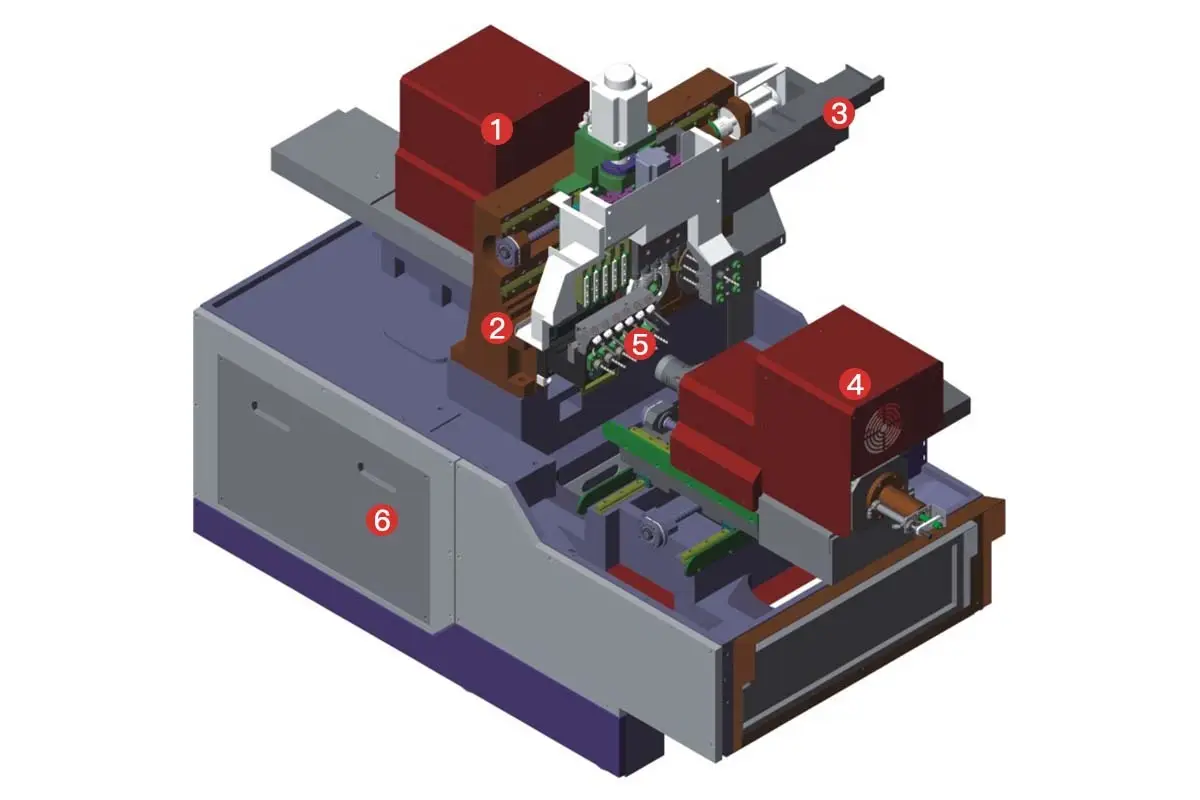

2. With this product, talent is more focused on its own business, and its work efficiency is higher, which ultimately helps to improve overall productivity. The base processed by gantry milling machine makes the product be of long service life

3. swiss type automatic lathe Selected high-quality materials, refined by first-class manufacturing technology, has the advantages of corrosion resistance, acid and alkali resistance, oxidation resistance, easy cleaning, no deformation, etc., durable and long service life.

4. swiss type automatic lathe It is refined through multiple production processes such as design, mold making, die-casting, and painting. It has good corrosion resistance and heat dissipation, reliable quality, and is durable.

5. swiss type automatic lathe Selected high-quality materials, combined with advanced production technology and craftsmanship, it is manufactured with excellent performance and high quality, and has the advantages of good wear resistance, anti-aging, anti-rust and corrosion resistance.

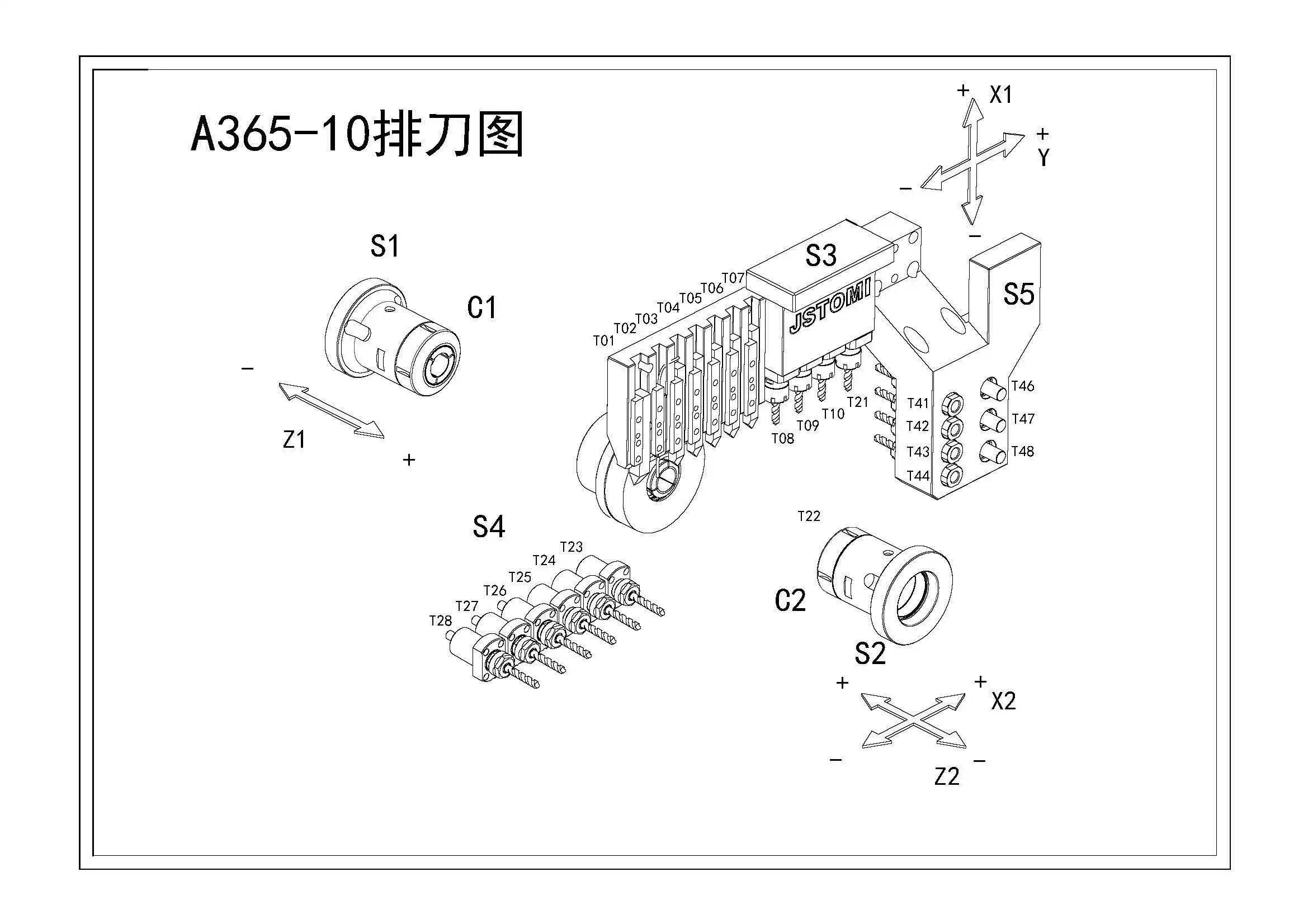

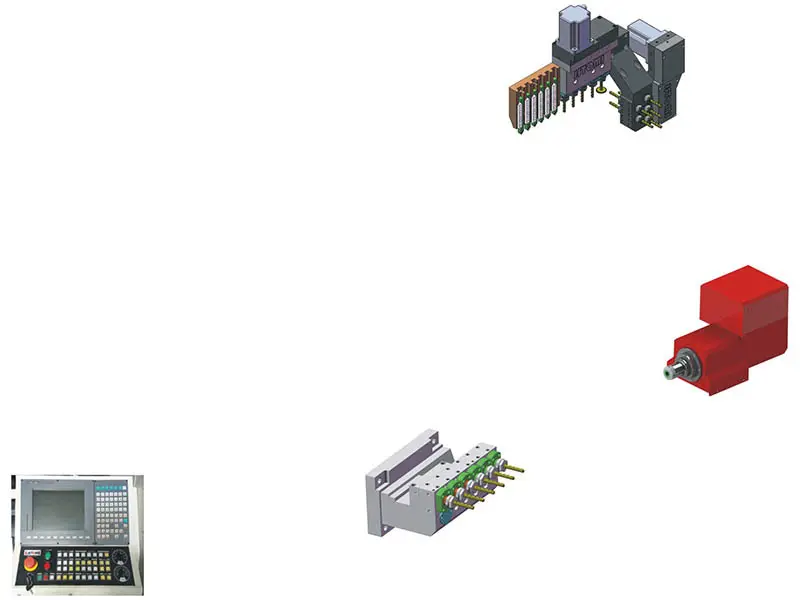

A365 twin spindle big diameter Swiss type lathe

Core product advantages

Machine parameter

PARAMETER | |||

A365 A A365C | |||

CONTROLLER | System | Syntec | Syntec |

rapid speed | 36m/min(X:24m/min) | 36m/min(X:24m/min) | |

PROCESSING RANGE | spindle clamping diameter | 7-35mm | 7-35mm |

one time feeding material length | 170mm | 170mm | |

spindle max drilling diameter | 14mm | 14mm | |

spindle max tapping diameter | M8*P1.25 | M8*P1.25 | |

Max lateral drilling hole diameter | 10mm | 10mm | |

SPINDLE | S1 spindle power | 4.4KW | 4.4KW |

S1 max speed | 6000rpm | 6000rpm | |

C1 indexing | 0.015° | 0.015° | |

spindle thru hole | 36mm | 36mm | |

SPINDLE TABLE STOKE | fixed sleeve | 170mm | 170mm |

movable sleeve | 170mm | 170mm | |

TOOLS | cutting tools | 6 tools 12*12 or 5 tool 16*16 (optional) | 6 tools 12*12 or 5 tools 16*16(optional) |

S3 lateral power tools | 5 ER16 living tool | 5 ER16 living tool | |

S3 lateral power tools Max speed. | 6000rpm | 6000rpm | |

S3 motor power | 1.0KW | 1.0KW | |

S5 end face tools | / | 5 fixed ER16+3 movavle(optional) | |

S5 max drilling diameter | / | 10mm | |

S5 Max. tapping diameter | / | M8*P1.25 | |

S5 lateral tools Max speed | / | 6000rpm | |

S5 motor power | / | 1.0KW | |

POWER | Y1 Z1 servo motor | 0.8KW | 0.8KW |

X1 servo motor | 1.3KW | 1.3KW | |

DIMENSION | Size( L x W x H ) | 1900*1300*1740mm | 1900*1300*1740mm |

N.W |

| 3450KG | 3500KG |

Company Features

1. We are equipped with a batch of scientific and technological elites. They are highly qualified in research and development, which makes them capable of customizing the most suitable products for customers.

2. Making the company the first swiss type automatic lathe manufacturer is the lifelong pursuit of every JSWAY person. Get info!