JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

utility Swiss lathe machine for plant

1. Standard manufacturing: JSWAY Swiss lathe machine is manufactured adopting the highest production standards at home and abroad. These standards include quality production system and operating system. The product comes with OEM service to meet customers' needs

2. The non-porous material enables this product to be extremely hygienic and ideal for frequent uses without the worry of bacterial accumulation. The base processed by gantry milling machine makes the product be of long service life

3. This product does not have the electric leakage problems. It is made of quality insulation materials and embedded with an insulation protection system to prevent electric danger. It is very easy to maintain, offering more convenience

4. The product has good mechanical properties. It has both good relative hardness (Mohs scale) and absolute hardness, which makes it resistant to the exterior impact. Each accessory of the product is self-made, ensuring its machining precision

5. The product features low internal impedance. The surface of its conductive substrate has been treated to enhance its static conductivity and collect microcurrent of the active material. With a full protective cover, it can prevent the water from flowing into it

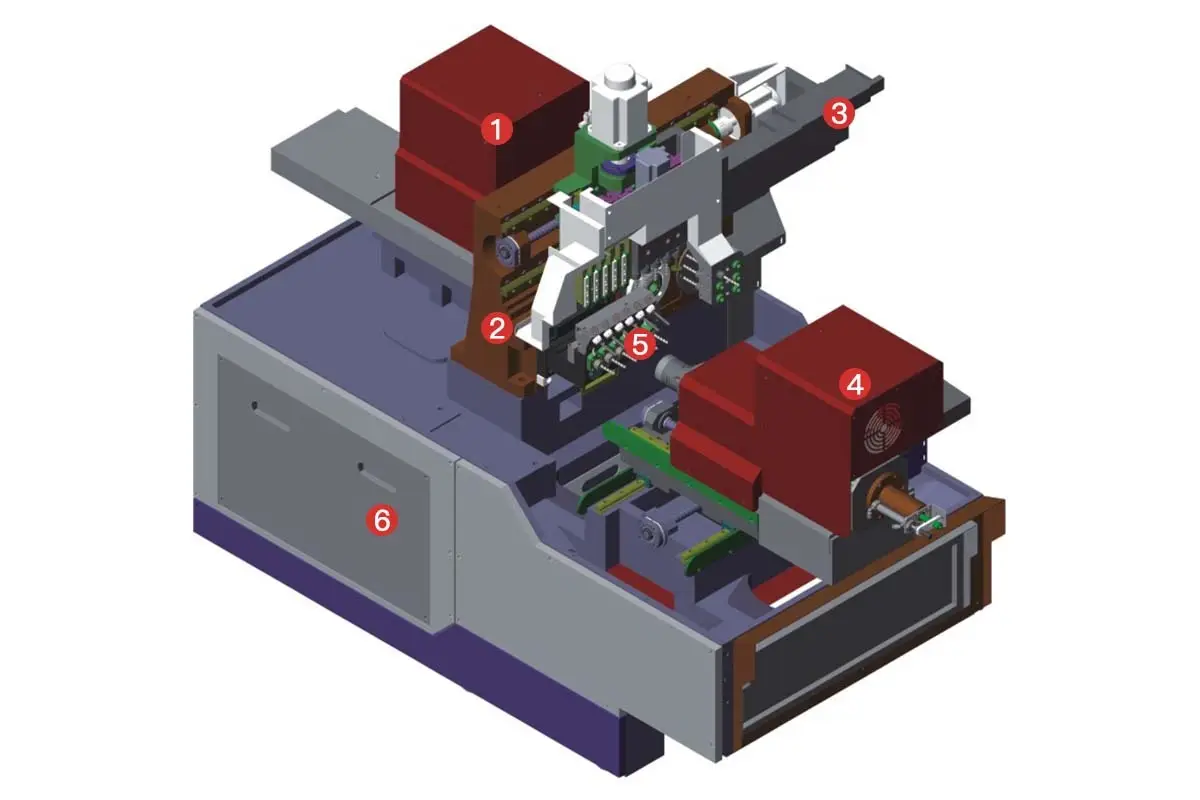

Core product advantages

Machine parameter

PARAMETER | |||

A366 | |||

CONTROLLER | System | Syntec | Syntec |

rapid speed | 36m/min(X:24m/min) | 36m/min(X:24m/min) | |

PROCESSING RANGE | spindle clamping diameter | 7-35mm | 7-35mm |

one time feeding material length | 170mm | 170mm | |

spindle max drilling diameter | 14mm | 14mm | |

spindle max tapping diameter | M8*P1.25 | M8*P1.25 | |

Max lateral drilling hole diameter | 10mm | 10mm | |

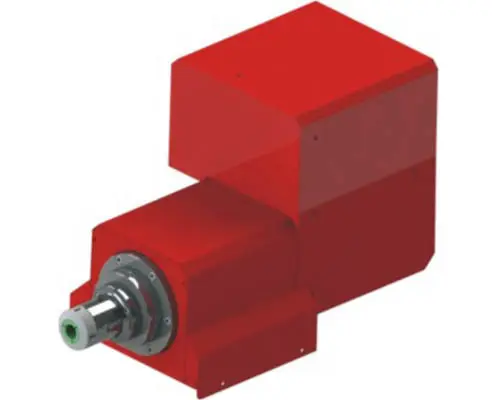

SPINDLE | S1 spindle power | 4.4KW | 4.4KW |

S1 max speed | 6000rpm | 6000rpm | |

C1 indexing | 0.015° | 0.015° | |

spindle thru hole | 36mm | 36mm | |

SPINDLE TABLE STOKE | fixed sleeve | 170mm | 170mm |

movable sleeve | 170mm | 170mm | |

TOOLS | cutting tools | 6 tools 12*12 or 5 tool 16*16 (optional) | 6 tools 12*12 or 5 tools 16*16(optional) |

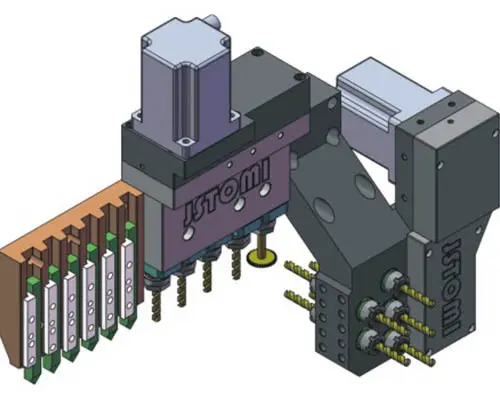

S3 lateral power tools | 5 ER16 living tool | 5 ER16 living tool | |

S3 lateral power tools Max speed. | 6000rpm | 6000rpm | |

S3 motor power | 1.0KW | 1.0KW | |

S5 end face tools | / | 5 fixed ER16+3 movavle(optional) | |

S5 max drilling diameter | / | 10mm | |

S5 Max. tapping diameter | / | M8*P1.25 | |

S5 lateral tools Max speed | / | 6000rpm | |

S5 motor power | / | 1.0KW | |

POWER | Y1 Z1 servo motor | 0.8KW | 0.8KW |

X1 servo motor | 1.3KW | 1.3KW | |

DIMENSION | Size( L x W x H ) | 1900*1300*1740mm | 1900*1300*1740mm |

N.W |

| 3450KG | 3500KG |

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has its own Swiss lathe machine R&D team, and we are fully capable of producing personalized products to meet your requirements.

2. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. intends to create a sustainable business with you! Inquire now!