JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

security токарно фрезерный станок с чпу cnc factory for factory

5-Axis Lathe Machine Manufacturer CNC Lathe With Y Axis

Features:

1. CNC lathe with y axis have engraving function. This feature allows for intricate designs and patterns to be engraved onto the surface of a workpiece, adding aesthetic value to the final product. With precise movements and control over the depth and width of the cuts, 5 axis CNC lathes with Y-axis can create detailed engravings on various materials such as metal, wood, plastic, and more. Not only does this improve the visual appeal of the end product but also adds uniqueness and personalization to it. Such versatility in function makes these machines an essential choice for industries that require both accuracy and creativity in their manufacturing processes. Overall, CNC lathe machines with Y-axis have revolutionized engraving capabilities in modern-day machining techniques.

2. CNC lathe with Y axis is for turning, side milling and drilling. This advanced CNC lathe, equipped with a Y axis, offers versatile capabilities for machining complex parts and components. With its ability to perform turning, side milling, and drilling operations in one setup, the cnc lathe machine CFG46Y3 is an efficient solution for reducing production time and increase productivity. Its rigid structure and precision engineering ensure high accuracy and repeatability in every cut. The Y axis feature allows for off-center machining, giving operators more flexibility in creating intricate shapes and contours. This lathe is also equipped with state-of-the-art controls that offer user-friendly programming options for optimal efficiency. Whether used in small batch or large volume production environments, the 5 axis CNC lathe CFG46Y3 provides exceptional performance to meet the demands of modern manufacturing processes.

3. CNC lathe with y axis have big space for machining, Z/X axis travel is long. It allows for larger and more complex workpieces to be machined with precision and accuracy. The y-axis also provides additional flexibility in the types of cutting operations that can be performed, including drilling, tapping, threading, and contouring. With a longer Z/X axis travel, CNC lathes with y axis are capable of handling a wider range of part sizes and shapes. This not only increases production capabilities but also reduces the need for multiple setups or repositioning of the workpiece, resulting in time and cost savings. Additionally, the combination of a y-axis and long Z/X axis travel enables simultaneous multi-tasking machining operations to be performed on different parts of the workpiece simultaneously, improving efficiency and reducing cycle times. Overall, CNC lathes with a y-axis provide manufacturers with enhanced versatility and productivity for their machining needs.

5. Japan gear, low sounds, high precision for Y axis living tool. 5 axis CNC lathe It offers a wide range of flexibility in terms of machining complex and intricate parts. The Y axis living tool feature allows for simultaneous machining on multiple axes, greatly reducing the need for re-positioning and improving overall efficiency. This powerful machine is capable of performing a variety of cutting operations, including facing, drilling, threading, grooving and contouring with unparalleled accuracy. Its compact design also makes it ideal for use in small or limited workspaces. With its advanced technology and precision capabilities, the 5 axis CNC lathe is an essential tool for any modern manufacturing facility looking to optimize production processes and achieve superior results.

6. Spindle with C-axis indexing function. This allows for the machining of complex cylindrical parts with features such as holes, grooves and threads at different angles. The C-axis indexing function works by rotating the workpiece on its center axis while it is being machined. This provides greater flexibility in creating intricate designs and improves accuracy in producing precise dimensions. In addition to the C-axis indexing, modern cnc lathes also have live tooling capabilities which further enhance their versatility. Live tooling allows for additional cutting operations to be performed without having to reposition the workpiece, saving time and increasing efficiency. With these advanced features, cnc lathes are able to produce a wide range of parts with high precision and complexity, making them an essential machine in many industries such as aerospace, automotive and medical manufacturing.

Technical Parameter :

NC | TAIWAN/GUANGZHOU | LNC/SYNTEC/GSK |

spindle | TaiWan Posa | A2-5/46 spindle |

X.Z axis servo motor | Japan YASKAWA | 1300 W |

Y axis servo motor | Japan YASKAWA | 750W |

spindle servo motor | Japan YASKAWA | 4.4 KW |

spindle servo pack | Japan YASKAWA | 5.5 KW |

lead screw/lead rail | TaiWan HIWIN/PMI | C3 , level two |

bearing | Japan NSK,Germany FAG | P4 level |

coupler for lead Screw | from Germany | high Precision |

Parameter |

|

|

Capacity | spindle bore | ¢56 mm |

Max. material diameter | ¢45 mm | |

Max. machining diameter | ¢350 mm | |

Max. length of machining | 200 mm | |

Max. travel of x-axis | 720 mm | |

Max. travel of z-axis | 280 mm | |

Max. travel of Y-axis | 155 mm | |

rapid speed (x-axis/z-axis) | 36/36/20 m/min | |

reposition accuracy | 0.005 mm | |

Motor | spindle servo motor | 4.4 KW |

spindle speed | 3000 rpm | |

X/Z-axis servo motor | 1300 W | |

Y-axis servo motor | 750 W | |

servo motor for power unit | 850 W / 750 W | |

Tools | gang type tools | 5--7 |

total living power tool unit | 3 | |

living tool holder size | ER20/25 | |

Other | total power | 7KW |

size( L x W x H ) | 2025*1385*1910 | |

N.W. | 2900 KGS |

Detailed Images

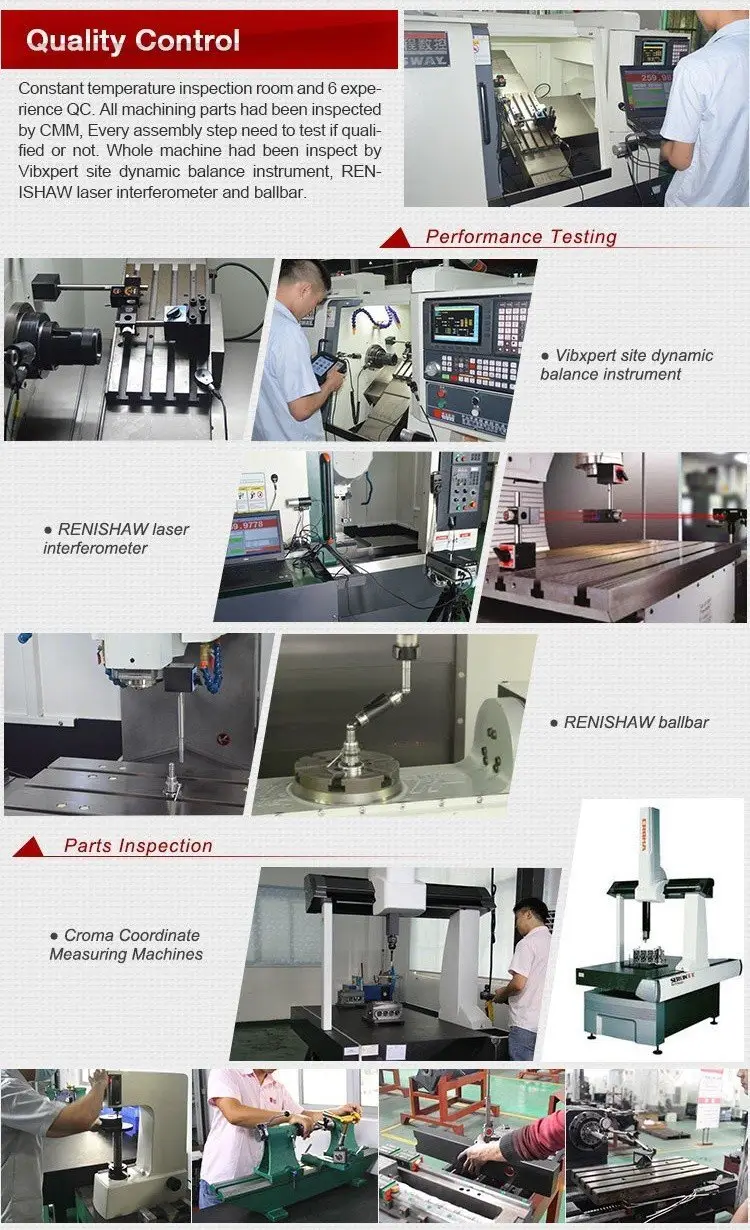

QC

Certifications

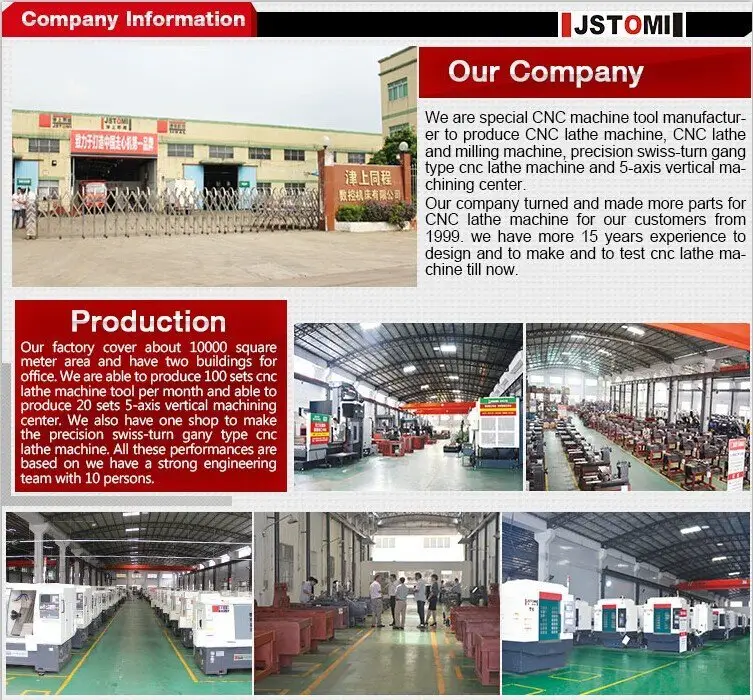

Company Information

Production Flow

Packaging & Shipping

Welcome to contact us if need any more information.