JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

safe vertical cnc machine lathes manufacturer for workplace

1. JSWAY cnc lathe definition has been tested for quality. All its main components, including the gears, pistons, engines and other moving parts, are tested to meet our established standards. Its cutting speed will not change even under the heavy cutting

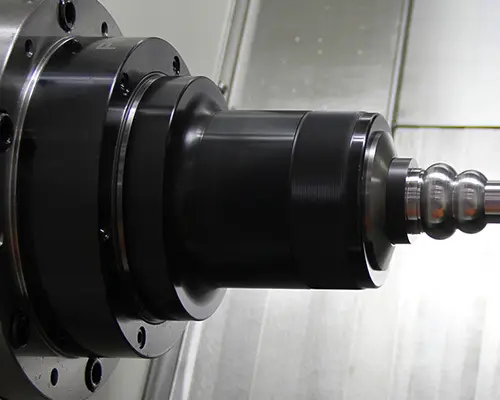

2. The service team in JSWAY has been specialized in vertical cnc machine industry for a long time. It will undergo a dynamic balance test to detect and correct the rotor, making it meet the requirements for use

3. This product has the required strength. Its elements are designed considering the forces acting on it, so it will not distort or break when loads are applied. The product is certified under CE and ISO 9001

Core product advantages

Machine parameter

PARAMETER | |||

CAPACITY |

| M46 | M56 |

Spindle bore | 56MM | 66 MM | |

Max. material diameter | 45MM | 52 MM | |

Max swing over bed | 350MM | 350mm | |

Max.lenght of machining | 100MM | 100 mm | |

Max. travel of X-axis | 715MM | 715 mm | |

Max. travel of Z-axis | 280MM | 280 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

MOTOR | Servo motor | 5.5KW | 7.5KW |

Spindle speed | 4500R/MIN | 3000 rpm/min | |

X-axis servo motor | 0.85KW | 1.3KW | |

Z-axis servo motor | 0.85KW | 1.3KW | |

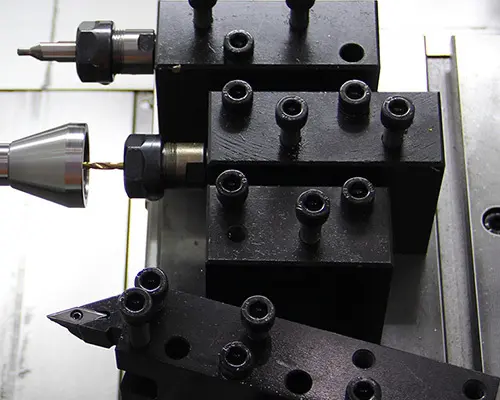

TOOLS | Gang type tools | 6-8 | 6-8 |

OTHERS | Total installed capacity | 9 KW | 13 KW |

Size | 2025X1385X1910 | 2025X1385X1910 | |

N.W. | 2700KG | 2750KG | |

MACHINING RANGE | ||||

COLLET | Diameter | Length | ||

CFG46 | CFG56 | CFG46 | CFG56 | |

4-45mm | 4-52 | 5-100mm | 5-80mm | |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-80mm |

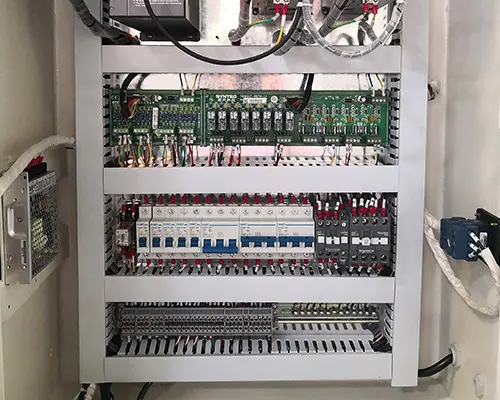

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is a leading solution supplier focusing on field of vertical cnc machine . Our company has an independent product development center and production base. It is well-equipped with state-of-the-art machinery for various product development and production.

2. Up to now, the factory has been equipped with multi manufacturing facilities, as well as necessary testing equipment. All of which are executed by following the ISO 9001 management system.

3. With introduced advanced technology and equipment, the factory coordinates the production through strict management to supply quality products for customers. Our goal is to provide clients with the best product solution and help their businesses grow. We attach importance to clients' problems and requirements and develop a strong and effective solution that works perfectly in their markets. Welcome to visit our factory!