JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

safe swiss type lathe big supplier for factory

- JSTOMI provides practical services based on different customer demand.

1. Manufacturing of JSWAY automatic lathe is a complex process. It begins with mining and then grinding raw materials to completion of heating, cooling, and drying.

2. In order to ensure the consistency of product quality, our technicians pay more attention to quality control and inspection in the production process.

3. The product has reliable performance and long service life.

4. People have no worry that it generates radiation that is harmful to health. Using this product will not have an adverse influence.

5. Because it needs little maintenance, it certainly helps manufacturers save repair costs as well as shortens the whole production schedule.

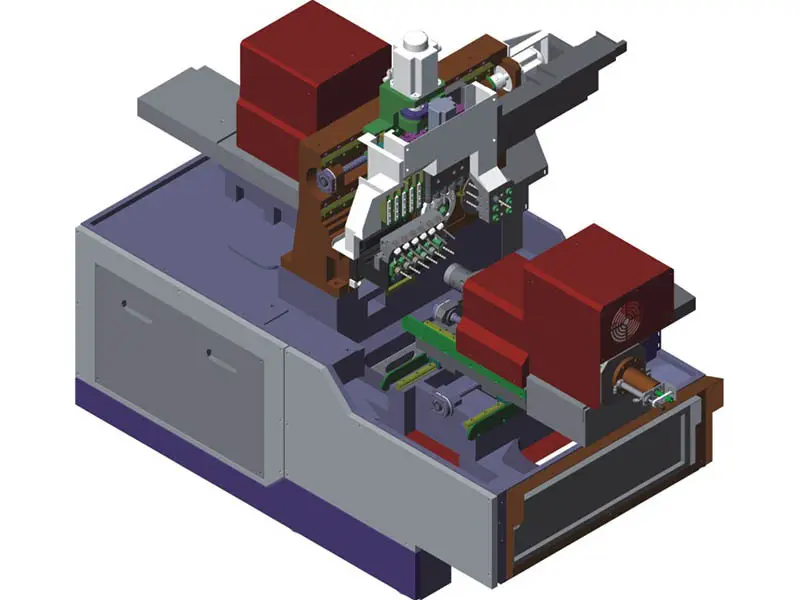

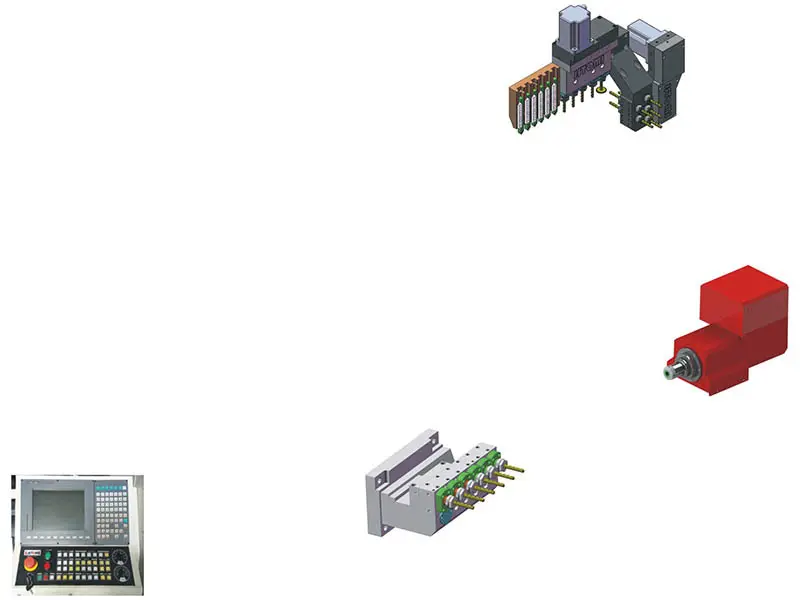

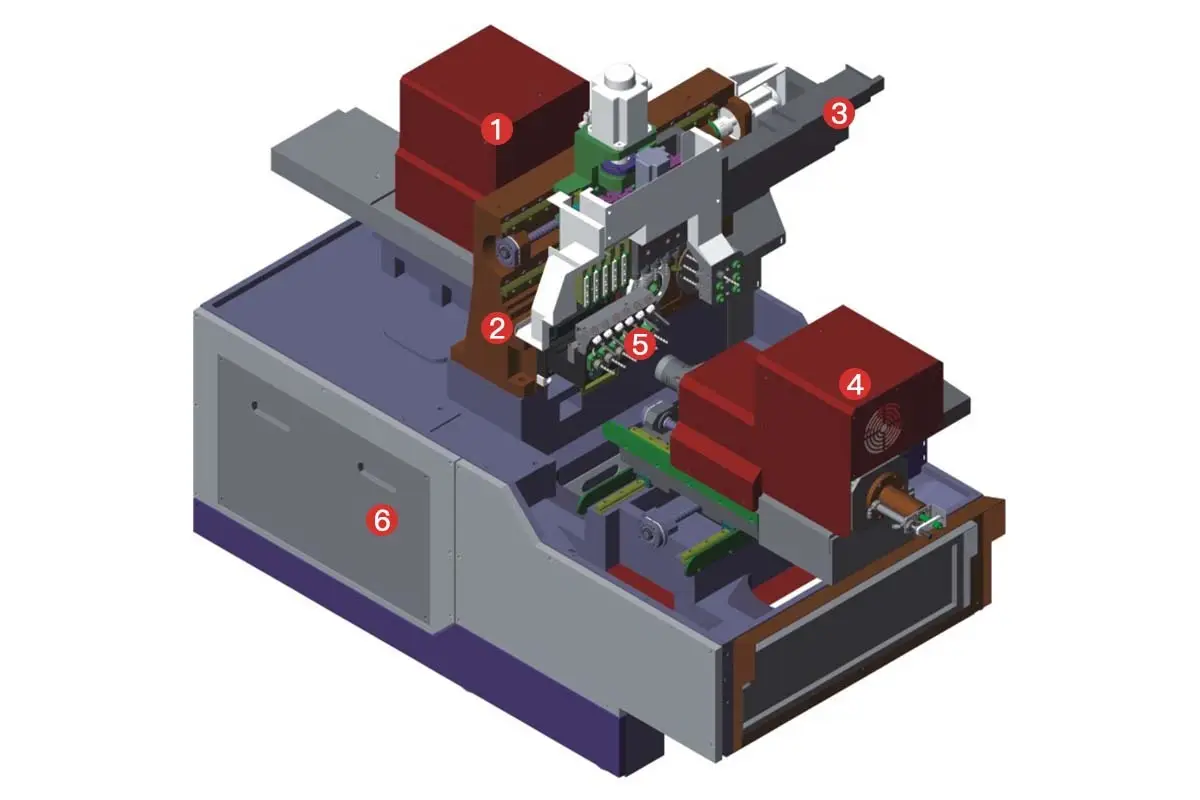

A365 twin spindle big diameter Swiss type lathe

Core product advantages

Machine parameter

PARAMETER | |||

A365 A A365C | |||

CONTROLLER | System | Syntec | Syntec |

rapid speed | 36m/min(X:24m/min) | 36m/min(X:24m/min) | |

PROCESSING RANGE | spindle clamping diameter | 7-35mm | 7-35mm |

one time feeding material length | 170mm | 170mm | |

spindle max drilling diameter | 14mm | 14mm | |

spindle max tapping diameter | M8*P1.25 | M8*P1.25 | |

Max lateral drilling hole diameter | 10mm | 10mm | |

SPINDLE | S1 spindle power | 4.4KW | 4.4KW |

S1 max speed | 6000rpm | 6000rpm | |

C1 indexing | 0.015° | 0.015° | |

spindle thru hole | 36mm | 36mm | |

SPINDLE TABLE STOKE | fixed sleeve | 170mm | 170mm |

movable sleeve | 170mm | 170mm | |

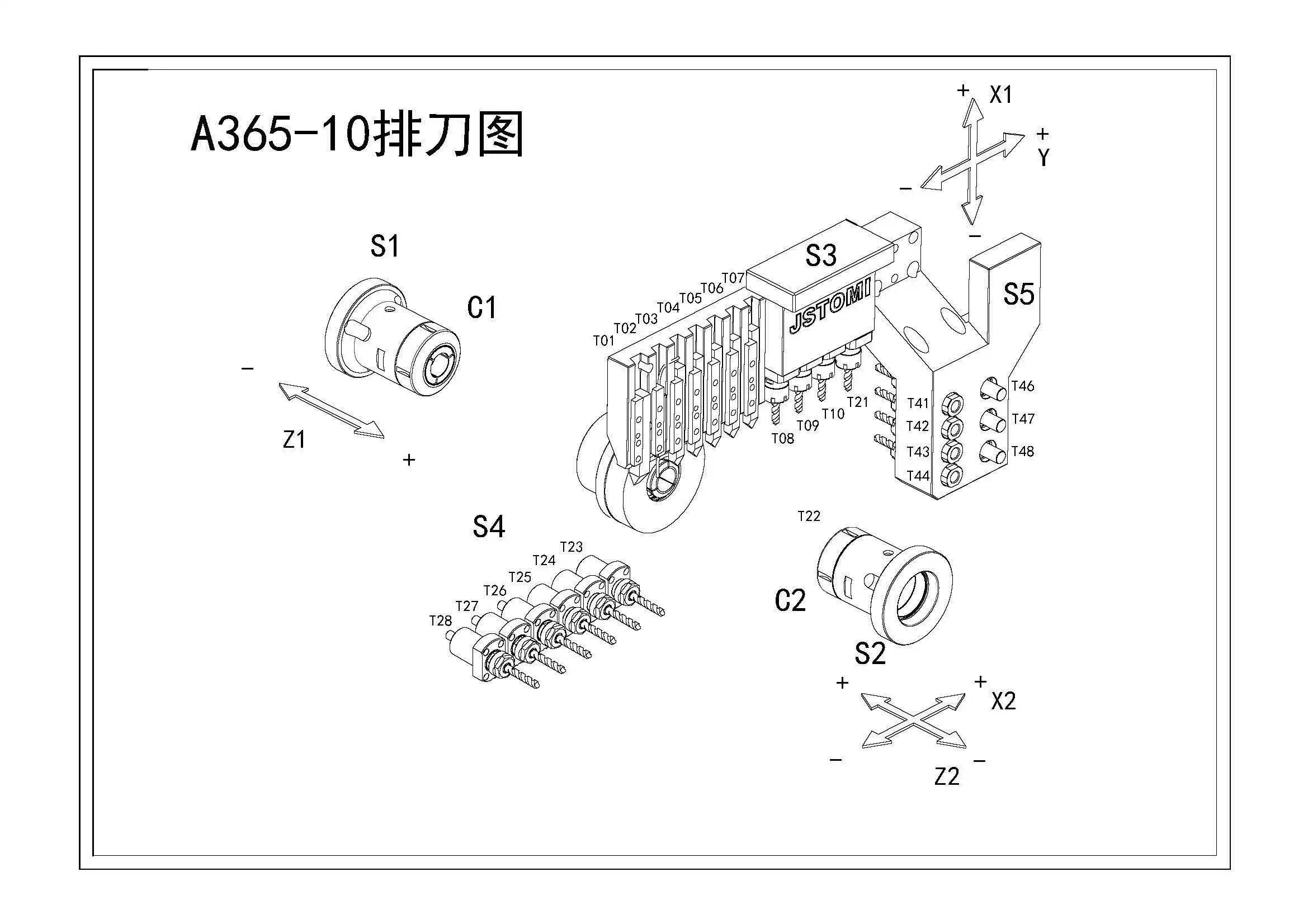

TOOLS | cutting tools | 6 tools 12*12 or 5 tool 16*16 (optional) | 6 tools 12*12 or 5 tools 16*16(optional) |

S3 lateral power tools | 5 ER16 living tool | 5 ER16 living tool | |

S3 lateral power tools Max speed. | 6000rpm | 6000rpm | |

S3 motor power | 1.0KW | 1.0KW | |

S5 end face tools | / | 5 fixed ER16+3 movavle(optional) | |

S5 max drilling diameter | / | 10mm | |

S5 Max. tapping diameter | / | M8*P1.25 | |

S5 lateral tools Max speed | / | 6000rpm | |

S5 motor power | / | 1.0KW | |

POWER | Y1 Z1 servo motor | 0.8KW | 0.8KW |

X1 servo motor | 1.3KW | 1.3KW | |

DIMENSION | Size( L x W x H ) | 1900*1300*1740mm | 1900*1300*1740mm |

N.W |

| 3450KG | 3500KG |

Company Features

1. JSWAY has become more and more influential in swiss type lathe industry.

2. Strong methods and sound quality management system guarantee the quality of Swiss-style lathe.

3. We will become a human-oriented and energy-saving company. To create a future that is green and clean for the next generations, we will try to upgrade our production process to reduce emission, waste, and carbon footprint. Our business goal is to be a dependable company across the world. We achieve this by deepening our techniques and strengthening the satisfaction of our clients.