JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

safe swiss lathe manufacturers jsway Chinese for workshop

- With the service concept of 'customer first, service first', JSTOMI constantly improves the service and strive to provide professional, high-quality and comprehensive services for customers.

1. The manufacturing process of JSWAY swiss lathe manufacturers involves coagulating the field latex with acid and passing the coagulated latex through cutting machines and a series of creping rollers.

2. The product features the desired electromagnetic compatibility. It doesn't emit a large amount of electromagnetic interference and it continues to function as intended in the presence of several electromagnetic phenomena.

3. This product is less likely to make mistakes in tasks, therefore leading to fewer errors as compared to human touch.

4. This product can make the work environment safer as having it means having fewer employees who perform tasks that can be dangerous and prone to injury.

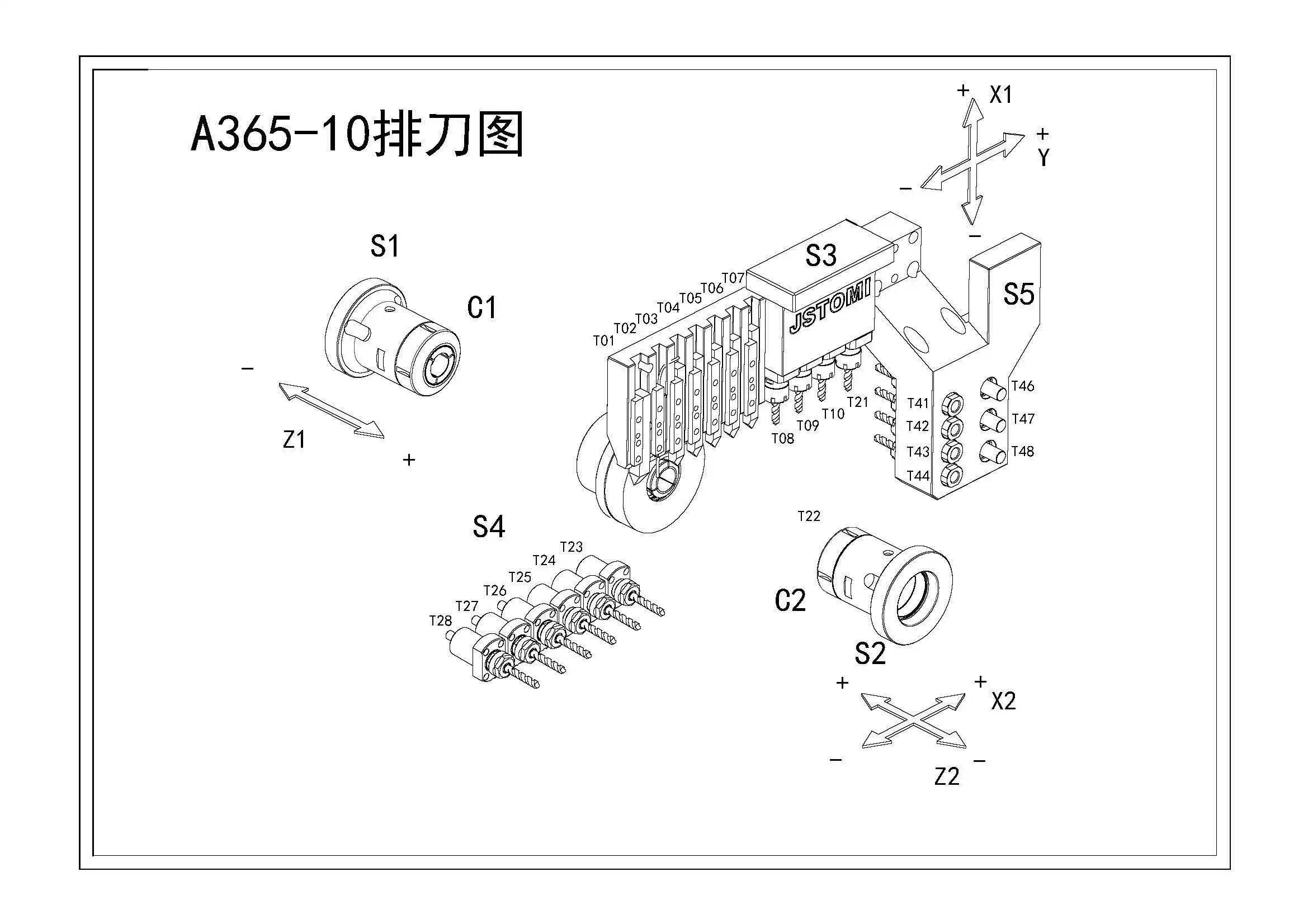

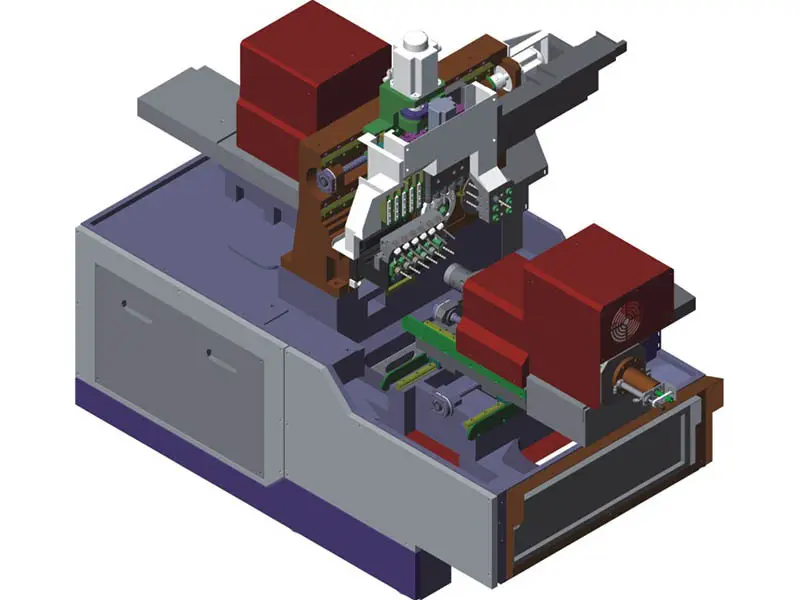

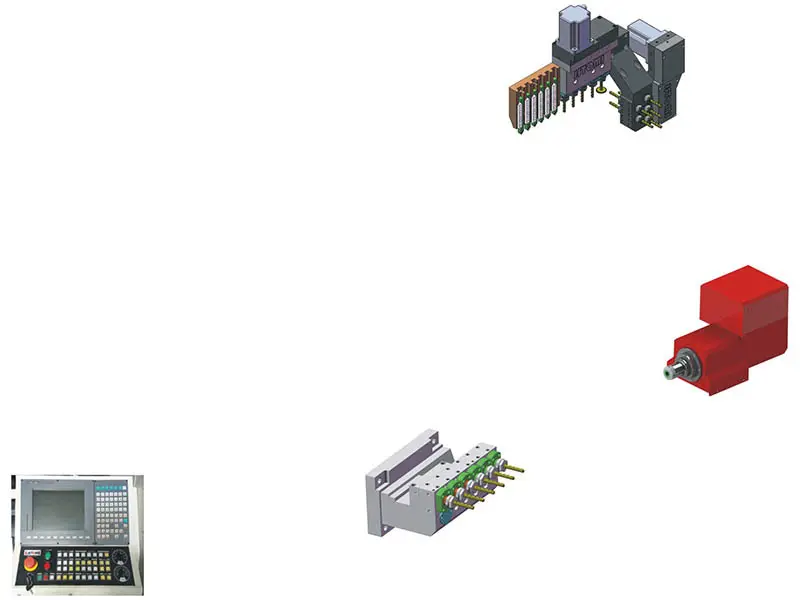

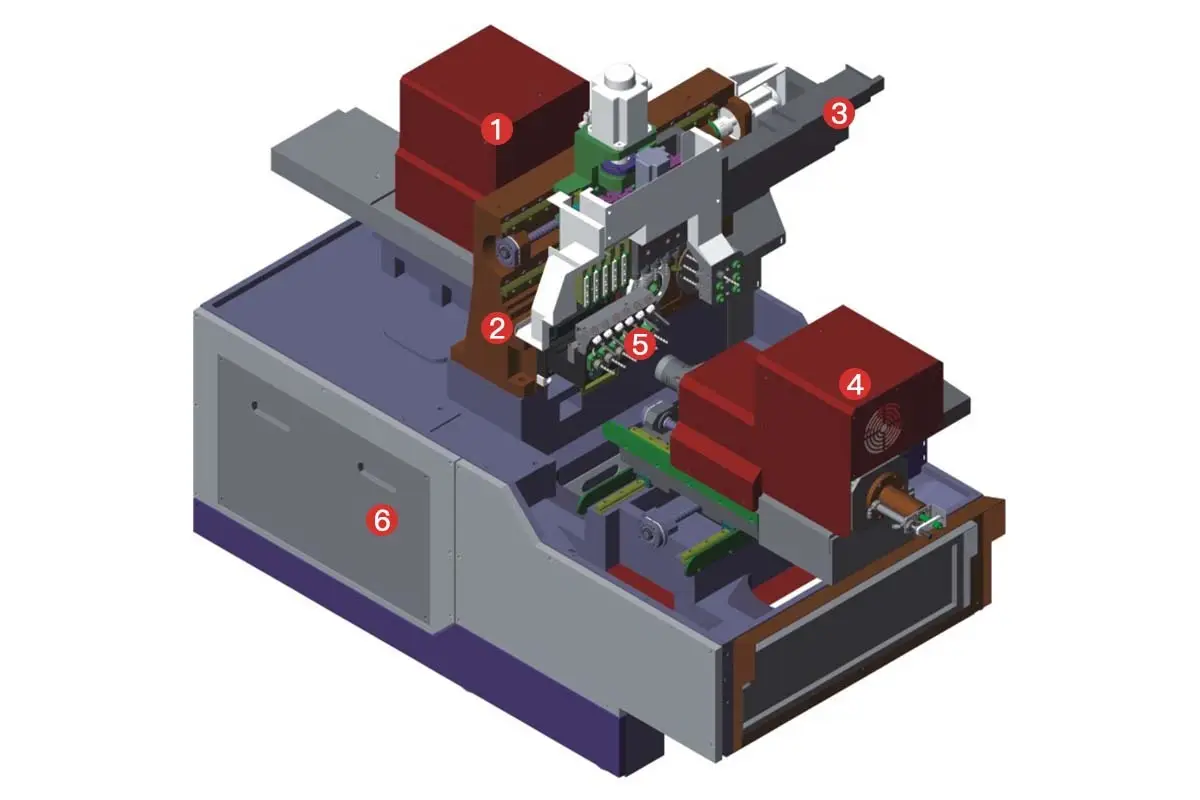

A365 twin spindle big diameter Swiss type lathe

Core product advantages

Machine parameter

PARAMETER | |||

A365 A A365C | |||

CONTROLLER | System | Syntec | Syntec |

rapid speed | 36m/min(X:24m/min) | 36m/min(X:24m/min) | |

PROCESSING RANGE | spindle clamping diameter | 7-35mm | 7-35mm |

one time feeding material length | 170mm | 170mm | |

spindle max drilling diameter | 14mm | 14mm | |

spindle max tapping diameter | M8*P1.25 | M8*P1.25 | |

Max lateral drilling hole diameter | 10mm | 10mm | |

SPINDLE | S1 spindle power | 4.4KW | 4.4KW |

S1 max speed | 6000rpm | 6000rpm | |

C1 indexing | 0.015° | 0.015° | |

spindle thru hole | 36mm | 36mm | |

SPINDLE TABLE STOKE | fixed sleeve | 170mm | 170mm |

movable sleeve | 170mm | 170mm | |

TOOLS | cutting tools | 6 tools 12*12 or 5 tool 16*16 (optional) | 6 tools 12*12 or 5 tools 16*16(optional) |

S3 lateral power tools | 5 ER16 living tool | 5 ER16 living tool | |

S3 lateral power tools Max speed. | 6000rpm | 6000rpm | |

S3 motor power | 1.0KW | 1.0KW | |

S5 end face tools | / | 5 fixed ER16+3 movavle(optional) | |

S5 max drilling diameter | / | 10mm | |

S5 Max. tapping diameter | / | M8*P1.25 | |

S5 lateral tools Max speed | / | 6000rpm | |

S5 motor power | / | 1.0KW | |

POWER | Y1 Z1 servo motor | 0.8KW | 0.8KW |

X1 servo motor | 1.3KW | 1.3KW | |

DIMENSION | Size( L x W x H ) | 1900*1300*1740mm | 1900*1300*1740mm |

N.W |

| 3450KG | 3500KG |

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. takes the lead to establish globally recognized swiss lathe manufacturers in the nation.

2. We have a modern factory that runs smoothly by complying with safety protocols. This means that our manufacturing workers are able to finish their products in an efficient and safe manner.

3. Sustainability continues to play a key part in our operation. We adopt an efficient process to reduce greenhouse gas emissions, energy consumption, solid landfill waste, and water consumption. We have established an effective environmental management method. We try to improve our production efficiency, reducing emissions and waste. Our company incorporates environmentally-friendly and sustainable practices. We adopt more energy-efficient production methods and machines for minimizing environmental impact. Our goal is highly motivating and clear, namely, to become a top player in the international markets. We will keep updating the product catalog, enhancing innovation, and offering better customer service.