JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

professional high speed lathe axis with tailstock for factory

1. While producing JSWAY lathe machine operations, we highly value the importance of raw materials and choose the top one of them.

2. high speed lathe is practical equipped with high-end lathe machine operations.

3. The product has value beyond its function and features.

4. Fast delivery, quality and quantity production are Zhongshan JSTOMI CNC Machine Tool Co., Ltd. 's advantages.

Core product advantages

Machine parameter

PARAMETER | |||

|

| CZG46D | CZG56D |

CAPACITY | Spindle bore | 56MM | 66 MM |

Max. material diameter: | 45MM | 52 MM | |

Max swing over bed | 350MM | 350mm | |

Max.lenght of machining | 100MM | 100 mm | |

Max. travel of X-axis | 720MM | 720 mm | |

Max. travel of Z-axis | 280MM | 280 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

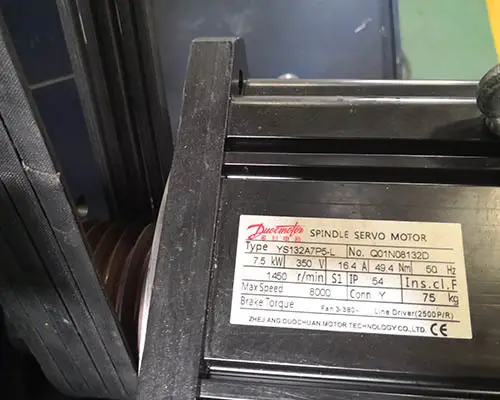

MOTOR | Servo motor | 7.5KW | 7.5KW |

Spindle speed | 4500R/MIN | 3000 rpm/min | |

X-axis servo motor | 1.3KW | 1.3KW | |

Z-axis servo motor | 1.3KW | 1.3KW | |

TOOLS | Turret | 8+3 | 8+3 |

OTHERS

| Total installed capacity | 9 KW | 13 KW |

Size | 2025X1385X1910 | 2025X1385X1910 | |

N.W. | 2700KG | 2750KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CZG46D | CZG56D | CZG46D | CZG56D | |

COLLET | 4-45mm | 4-52 | 5-100mm | 5-80mm |

CHUCK | 4-140mm | 4-160mm | 5-100mm | 5-80mm |

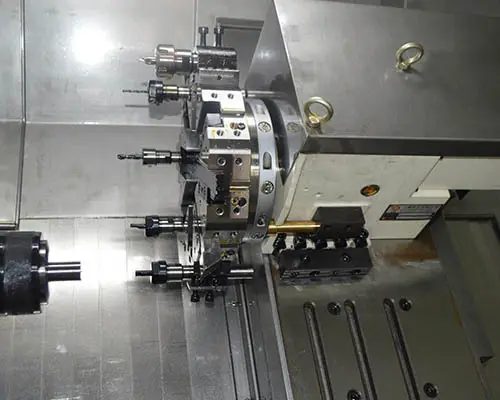

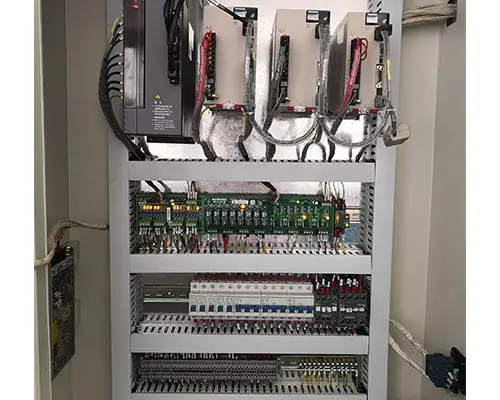

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has been focusing on the R&D, design, and manufacture of lathe machine operations and we are constantly appraised by many customers.

2. We have an excellent team of customer service professionals. They are excel at effective communication with clients. They not only listen to clients' needs but also actively concern clients' feedback around current products and services, and generate ideas on how to make improvements.

3. The goal of our company is to become an innovative and distinctive manufacturing company. We will invest more in introducing advanced and high-tech manufacturing and developing facilities which can help us to broaden our product range. Our pledge to our customers is “quality and safety”. From the incoming materials inspection, components inspection, to the piece quality inspection, we promise to do best and offer the desired requirements. We put sustainable development as our top priority. Under this task, we will invest more in introducing green and sustainable manufacturing machines which generate less carbon footprint. We are committed to promoting our sustainable development. We are constantly improving our staff's environmental awareness and put it into our production activities.