JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

precise cnc swiss lathe lathe Chinese for plant

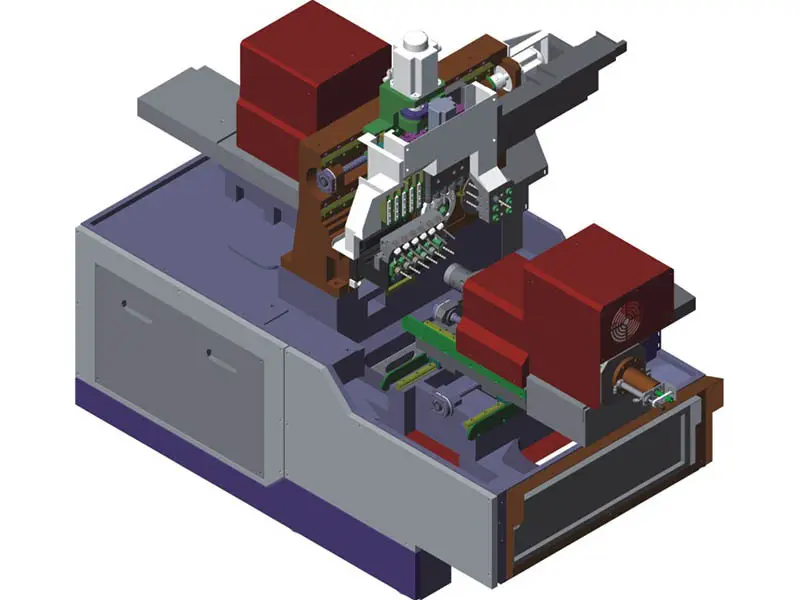

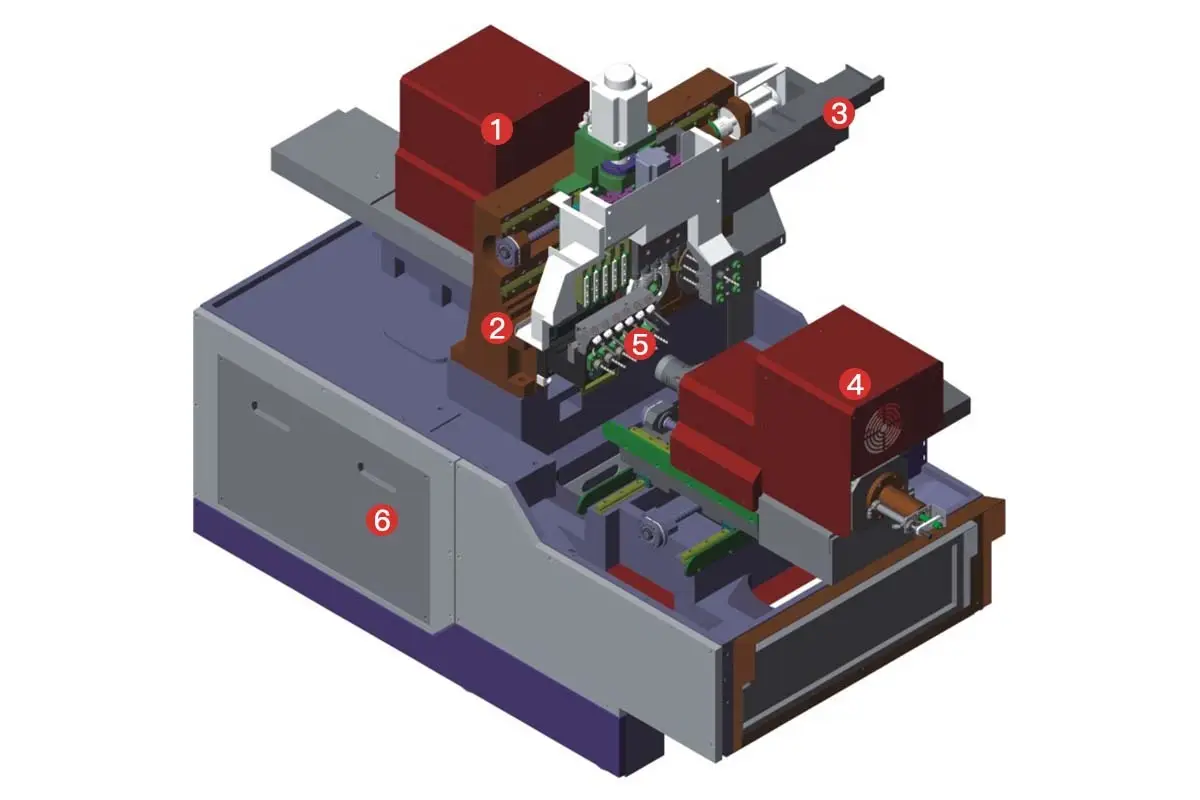

1. The body of cnc swiss lathe is made by advanced swiss lathe , which is swiss type cnc lathe .

2. The product features an easy operation. It has a relatively simple operating system combining a powerful processing flow and provides simple operation instruction.

3. Products have a major impact on productivity. With its high efficiency, it enables workers to work more quickly before the deadline.

4. This product serves as a useful tool to increase productivity and efficiency. The use of this product can cut down operation times and workload.

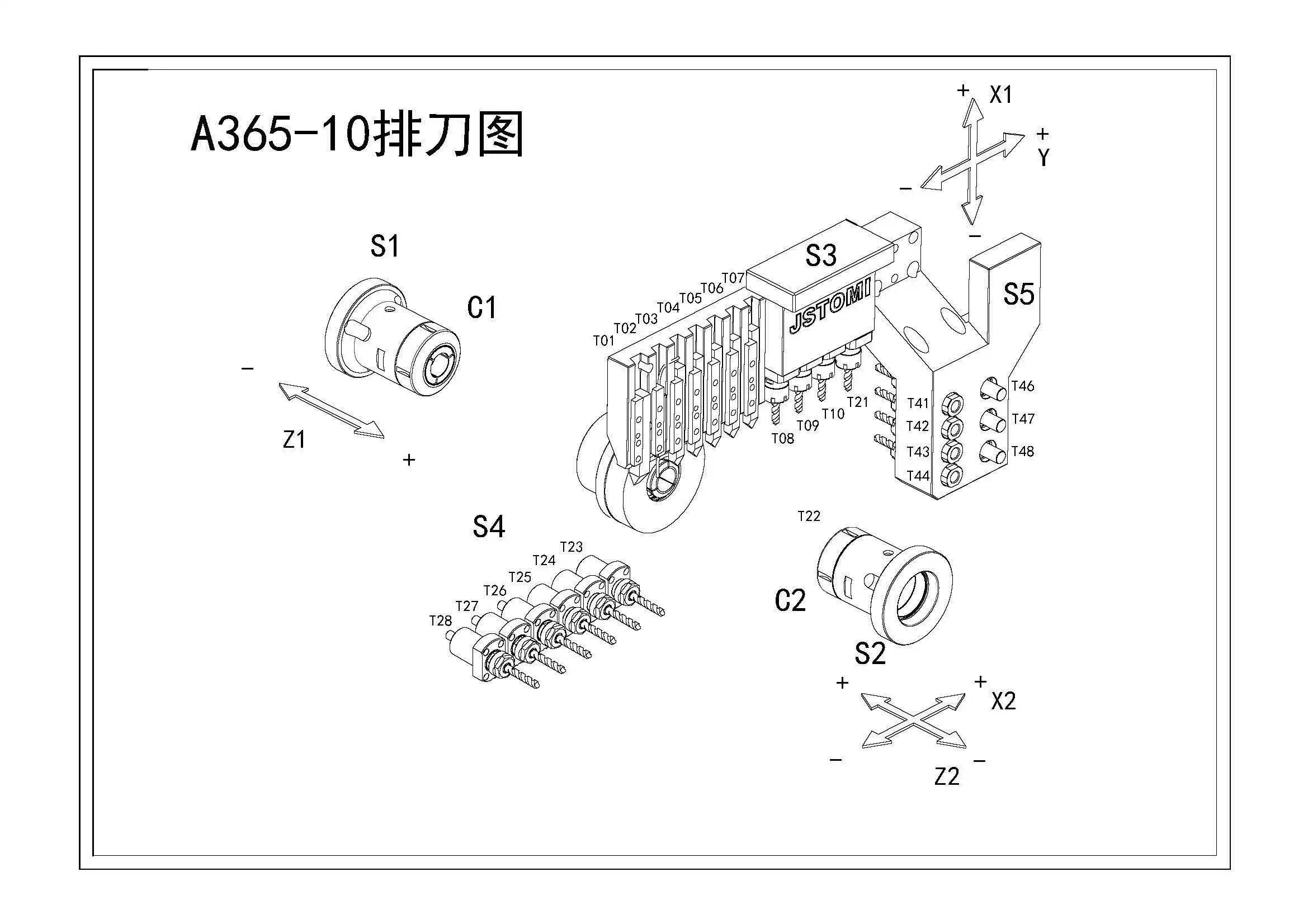

A365 twin spindle big diameter Swiss type lathe

Core product advantages

Machine parameter

PARAMETER | |||

A365 A A365C | |||

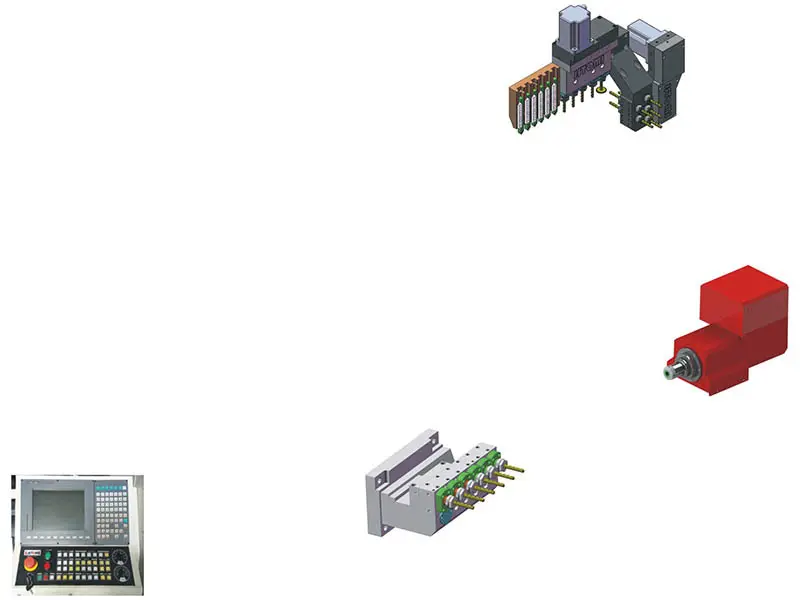

CONTROLLER | System | Syntec | Syntec |

rapid speed | 36m/min(X:24m/min) | 36m/min(X:24m/min) | |

PROCESSING RANGE | spindle clamping diameter | 7-35mm | 7-35mm |

one time feeding material length | 170mm | 170mm | |

spindle max drilling diameter | 14mm | 14mm | |

spindle max tapping diameter | M8*P1.25 | M8*P1.25 | |

Max lateral drilling hole diameter | 10mm | 10mm | |

SPINDLE | S1 spindle power | 4.4KW | 4.4KW |

S1 max speed | 6000rpm | 6000rpm | |

C1 indexing | 0.015° | 0.015° | |

spindle thru hole | 36mm | 36mm | |

SPINDLE TABLE STOKE | fixed sleeve | 170mm | 170mm |

movable sleeve | 170mm | 170mm | |

TOOLS | cutting tools | 6 tools 12*12 or 5 tool 16*16 (optional) | 6 tools 12*12 or 5 tools 16*16(optional) |

S3 lateral power tools | 5 ER16 living tool | 5 ER16 living tool | |

S3 lateral power tools Max speed. | 6000rpm | 6000rpm | |

S3 motor power | 1.0KW | 1.0KW | |

S5 end face tools | / | 5 fixed ER16+3 movavle(optional) | |

S5 max drilling diameter | / | 10mm | |

S5 Max. tapping diameter | / | M8*P1.25 | |

S5 lateral tools Max speed | / | 6000rpm | |

S5 motor power | / | 1.0KW | |

POWER | Y1 Z1 servo motor | 0.8KW | 0.8KW |

X1 servo motor | 1.3KW | 1.3KW | |

DIMENSION | Size( L x W x H ) | 1900*1300*1740mm | 1900*1300*1740mm |

N.W |

| 3450KG | 3500KG |

Company Features

1. JSWAY has been spent years of efforts into developing high quality cnc swiss lathe .

2. By performing high technology, JSWAY is able to ensure the quality of the swiss type lathe .

3. We love taking care of our customers and take great pleasure in their satisfaction. Each and every customer is given a great deal of care and consideration. Please contact us! From the efficiency of our buildings to our progress in managing energy, water, and waste, we continue to find ways to reduce the company's impact on the environment and embed sustainability throughout our businesses.