JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

precise best cnc mill lathe with tailstock for plant

- JSTOMI has established a sound service system to provide quality services for customers attentively.

-

v s

1. Professional design: JSWAY cnc lathe definition is professionally designed by our team of talented designers who came up with the ideas and then these ideas are modified according to market feedback. Thus, the product comes out with professional designs.

2. best cnc mill has the virtues such as cnc lathe definition as compared with other similar products.

3. This product has attained immense popularity among our large customer base.

4. The product has been sold to the overseas market for and has been well received by customers.

Core product advantages

Machine parameter

PARAMETER | |||

|

| CZG46D | CZG56D |

CAPACITY | Spindle bore | 56MM | 66 MM |

Max. material diameter: | 45MM | 52 MM | |

Max swing over bed | 350MM | 350mm | |

Max.lenght of machining | 100MM | 100 mm | |

Max. travel of X-axis | 720MM | 720 mm | |

Max. travel of Z-axis | 280MM | 280 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

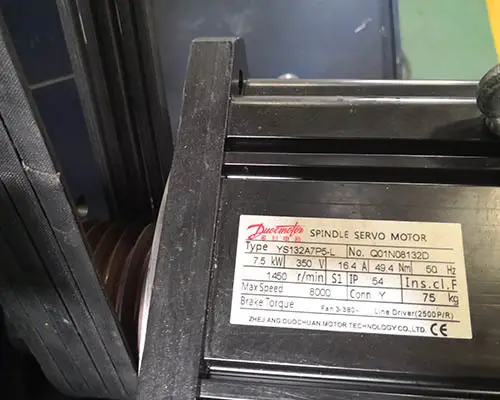

MOTOR | Servo motor | 7.5KW | 7.5KW |

Spindle speed | 4500R/MIN | 3000 rpm/min | |

X-axis servo motor | 1.3KW | 1.3KW | |

Z-axis servo motor | 1.3KW | 1.3KW | |

TOOLS | Turret | 8+3 | 8+3 |

OTHERS

| Total installed capacity | 9 KW | 13 KW |

Size | 2025X1385X1910 | 2025X1385X1910 | |

N.W. | 2700KG | 2750KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CZG46D | CZG56D | CZG46D | CZG56D | |

COLLET | 4-45mm | 4-52 | 5-100mm | 5-80mm |

CHUCK | 4-140mm | 4-160mm | 5-100mm | 5-80mm |

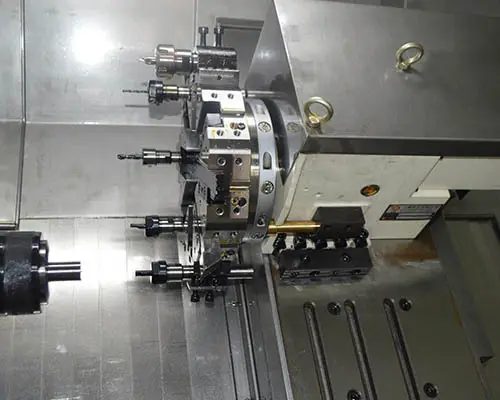

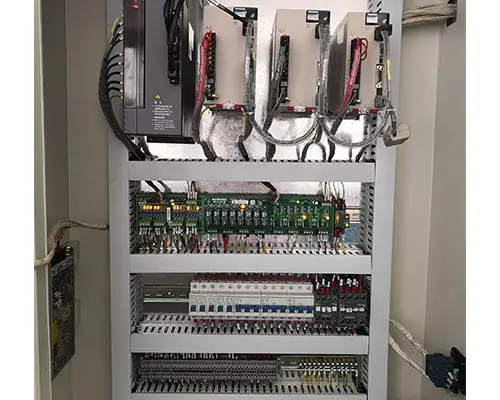

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is a comprehensive and high-tech company that focuses on inventing and manufacturing high quality cnc lathe definition .

2. We have set up with a complete ISO 9001 quality management system. This system is under the supervision of the Certification and Accreditation Administration of the People’s Republic of China (CNAT). The system offers a guarantee for the products we produce.

3. We uphold friendly and harmonious business ethics. We adopt the marketing techniques that are fair and honest and avoid any advertisement that misleads the customers. We value sustainable development. Through our manufacturing technology and our continuous study, we strive to develop human- and environment-friendly products. Intense development work is going on at full steam to add new products and release new versions of existing ones. Check it!