JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

multi function 5 axis cnc milling machine high efficiency for military parts

1. JSWAY 4 axis cnc lathe is manufactured under professionalism. Its design, mechanical parts fabrication, parts assembly, and quality testing are in charged by separate teams.

2. The product functions properly in an environment with a certain level of electromagnetic disturbance. It won't be easily affected by other devices.

3. The chief advantage in the use of this product is the shorter period of production because of its quick-yielding power.

4. This product is needed as it is able to boost accuracy in the workplace. It can reduce the chances of errors.

Core product advantages

Machine parameter

PARAMETER | ||

|

| B8D |

CAPACITY | Spindle bore | 56 MM |

Max. material diameter: | 45 MM | |

Max swing over bed | 350mm | |

Max. length of machining | 100 mm | |

Max. travel of X-axis | 630 mm | |

Max. travel of Z-axis | 300 mm | |

X/Y/Z fast moving | 36/20/36m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | |

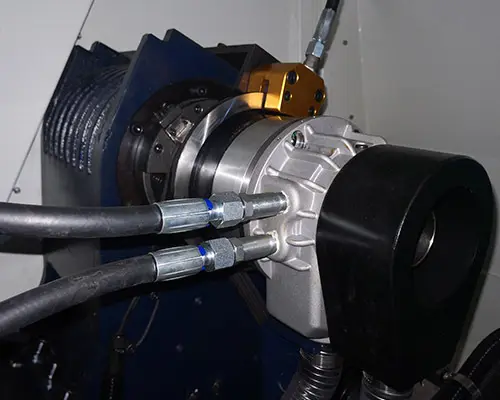

MOTOR | Servo motor | 5.9KW with magnet ring |

Spindle speed | 5000 rpm/min | |

X-axis servo motor | 1.3KW | |

Z-axis servo motor | 1.3KW | |

Y axis servo mot0r | 850W | |

Living tool servo motor | 1.3KW | |

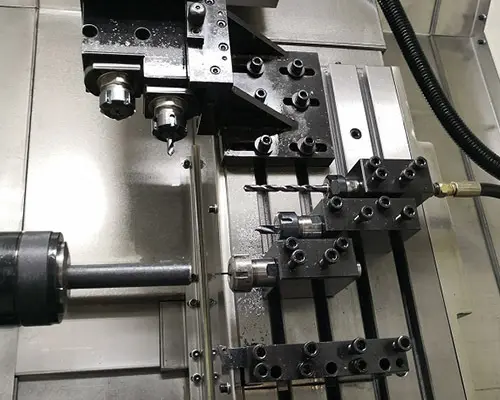

TOOLS | turret | 8/12 tools |

OTHERS

| Total installed capacity | 12 KW |

Size | 2200X1723X2023 | |

N.W. | 2950KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CFG46X | M46X | CFG46X | M46X | |

COLLET | 4-45mm | 4-45mm | 5-100mm | 5-100mm |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-100mm |

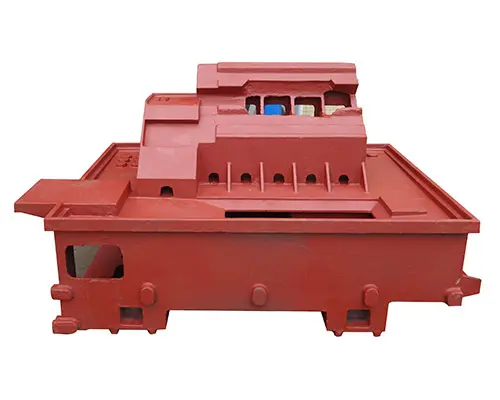

Details of the figure

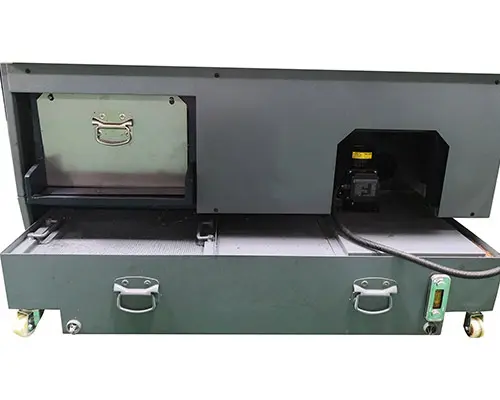

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. With the emergence and broad development prospect of 5 axis cnc milling machine , Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has becomes more and more popular.

2. We have an export license issued by the National Foreign Trade and Economic Cooperation Administrative Department. The export license has enabled us to unlock the international market and expand the scope operation.

3. We work hard to protect and preserve environmental integrity. We incorporate many sustainability plans into each of our production processes, such as reducing waste discharge, save water and electricity, and make full use of resources. We integrate sustainability into the anatomy of how we help our customers succeed and how we run our operations. And we believe it will be a win-win from both a commercial and sustainability perspective. We have been always adhering to the business philosophy of "market-oriented and customer-oriented and people-oriented team management thought". We would like to absorb new ideas to continuously improve ourself.