JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

multi function 3 axis lathe machineslant supplier for car parts

- JSTOMI constantly improves the service system and creates a healthy and excellent service structure.

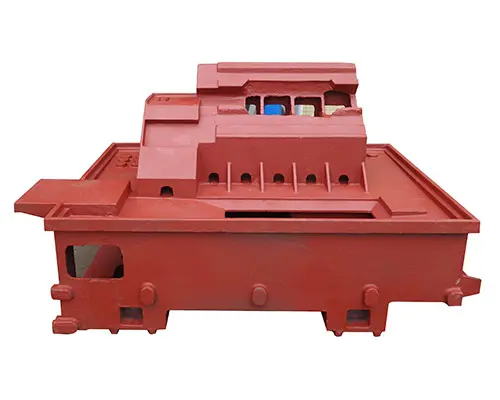

1. JSWAY turning lathe is made using sophisticated technology and high-grade materials.

2. This machine has the desired motion. Various possible mechanisms are shortlisted and analyzed during the design phase, and the best mechanism is selected for its design.

3. The adoption of this product promotes the reform of production methods. Manufacturers can be seen in the increase in labor productivity and the reduction in human capital costs.

4. This product not only meets the social production demand for energy and efficiency, but also provides a guarantee for the diversified development of high technology.

Core product advantages

Machine parameter

PARAMETER | |||

|

| CFG46X | M46X |

CAPACITY | Spindle bore | 56MM | 56 MM |

Max. material diameter: | 45MM | 45 MM | |

Max swing over bed | 280MM | 350mm | |

Max. length of machining | 100MM | 100 mm | |

Max. travel of X-axis | 720MM | 850 mm | |

Max. travel of Z-axis | 280MM | 330 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

MOTOR | Servo motor | 4.4KW | 5.9/7.5KW with magnet ring |

Spindle speed | 3000R/MIN | 5000 rpm/min | |

X-axis servo motor | 1.3KW | 1.3KW | |

Z-axis servo motor | 1.3KW | 1.3KW | |

Living tool servo motor | 0.85/1.3KW | 0.85/1.3KW | |

TOOLS | Gang type tools | 2-8 | 2-8 |

OTHERS | Total installed capacity | 12 KW | 12 KW |

Size | 2025X1385X1910 | 2180X1623X1940 | |

N.W. | 2700KG | 2950KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CFG46X | M46X | CFG46X | M46X | |

COLLET | 4-45mm | 4-45mm | 5-100mm | 5-100mm |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-100mm |

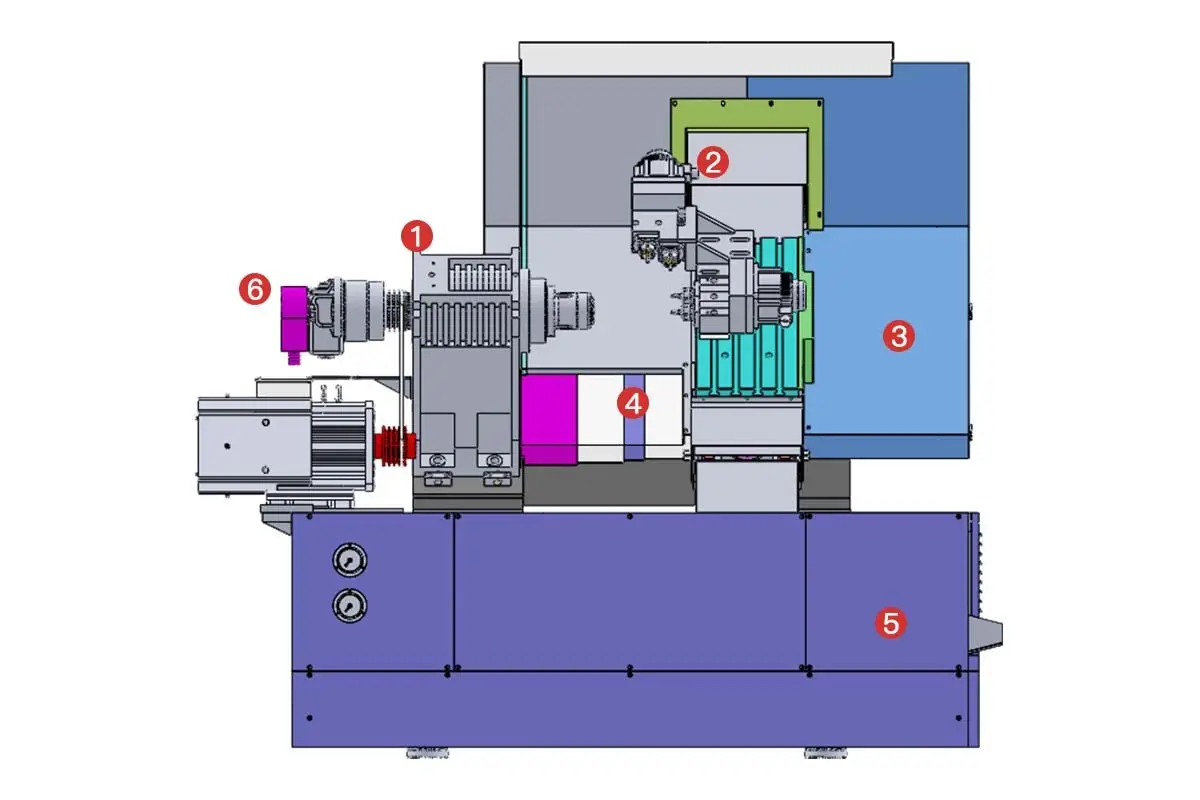

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has a technical R&D team and has been dedicated to the research and development of 3 axis lathe machine.

2. Our modern factory is equipped with highly advanced production facilities under the principles of zero pollution and cost efficiency.

3. We are guided by our sustainable development goals. We will develop and manufacture our products in a way that ensures they are safe, environmentally friendly and economical. We understand our role in social sustainability development. We use the technologies, materials, and equipment which reduce the negative impact on the environment.