JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY utility swiss lathe high efficiency for plant

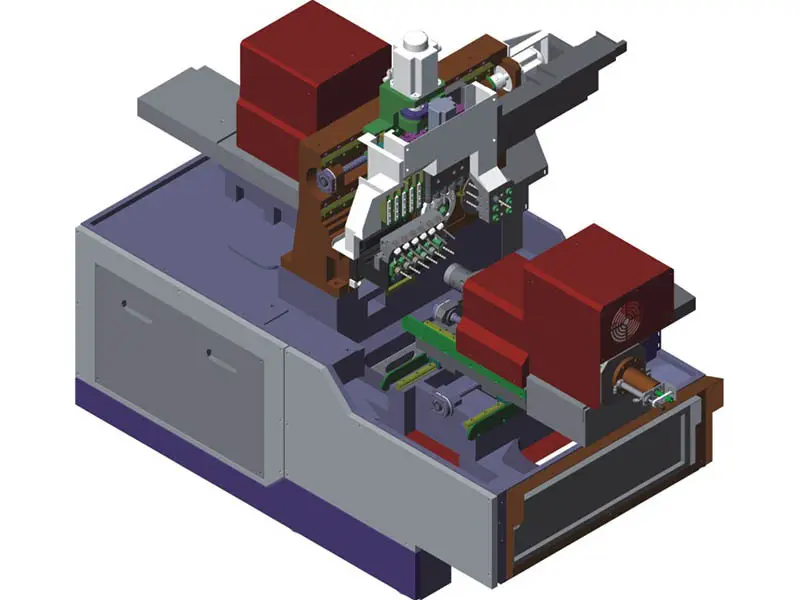

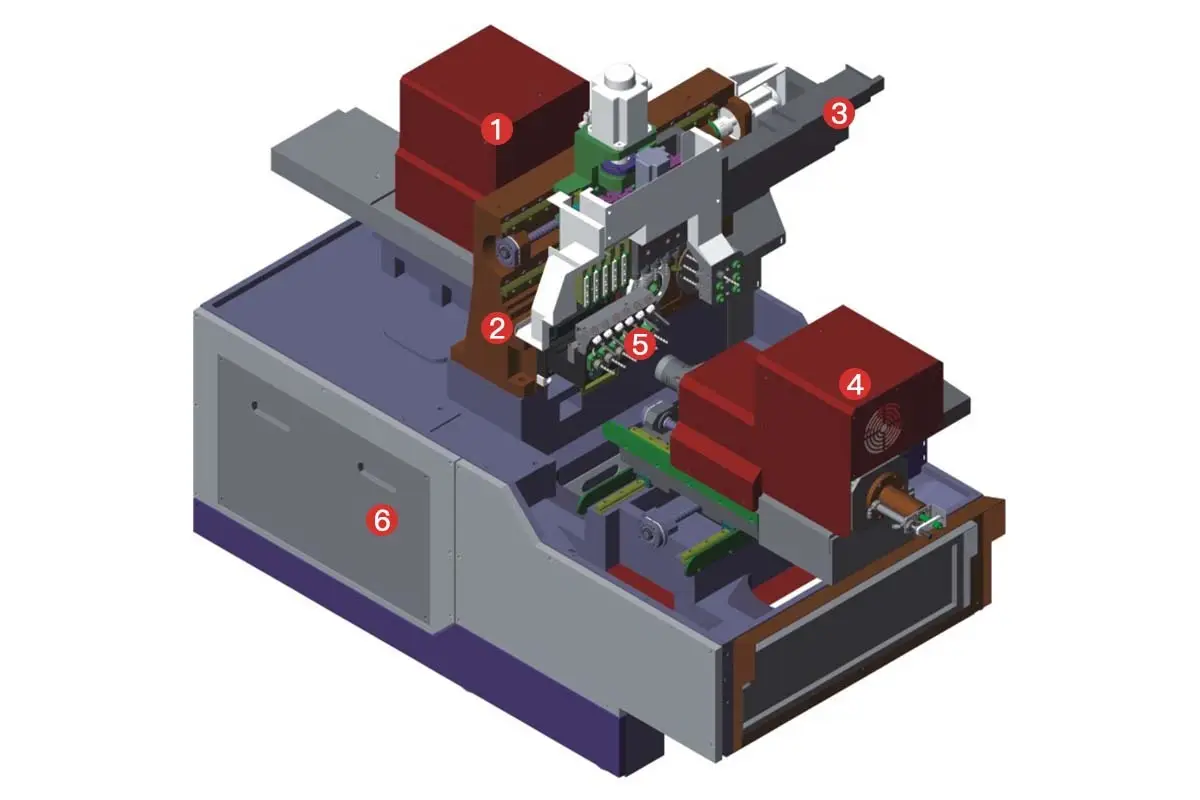

1. The production technique of JSWAY is updated based on the lighting market trend. It has evolved greatly over the past years. Its parts are installed firmly, which will prevent the deflection or vibration from happening

2. With the advanced equipment, we concentrate on the quality of the products. The base processed by gantry milling machine makes the product be of long service life

3. The product has excellent flexibility and endurance. It is able to repeat the movement for thousands of times without malfunction. Its key parts are all purchased from Taiwan and Japan brand, making the product stable in performance

4. This product has a high yield. Once the design basic parameters and standard specifications are entered into the product, it can perform high-volume daily tasks from start to finish and provide flexible scalability. Its interface is designed to be simple and elegant

A365 twin spindle big diameter Swiss type lathe

Core product advantages

Machine parameter

PARAMETER | |||

A365 A A365C | |||

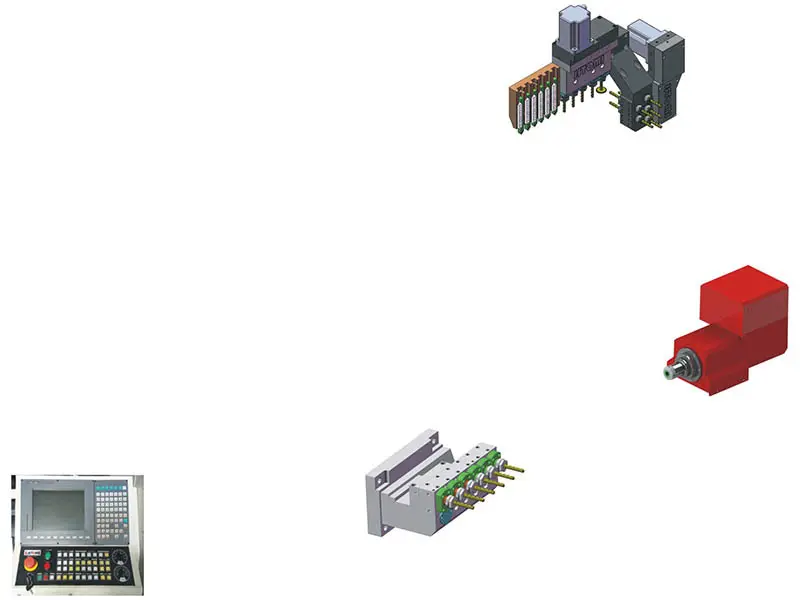

CONTROLLER | System | Syntec | Syntec |

rapid speed | 36m/min(X:24m/min) | 36m/min(X:24m/min) | |

PROCESSING RANGE | spindle clamping diameter | 7-35mm | 7-35mm |

one time feeding material length | 170mm | 170mm | |

spindle max drilling diameter | 14mm | 14mm | |

spindle max tapping diameter | M8*P1.25 | M8*P1.25 | |

Max lateral drilling hole diameter | 10mm | 10mm | |

SPINDLE | S1 spindle power | 4.4KW | 4.4KW |

S1 max speed | 6000rpm | 6000rpm | |

C1 indexing | 0.015° | 0.015° | |

spindle thru hole | 36mm | 36mm | |

SPINDLE TABLE STOKE | fixed sleeve | 170mm | 170mm |

movable sleeve | 170mm | 170mm | |

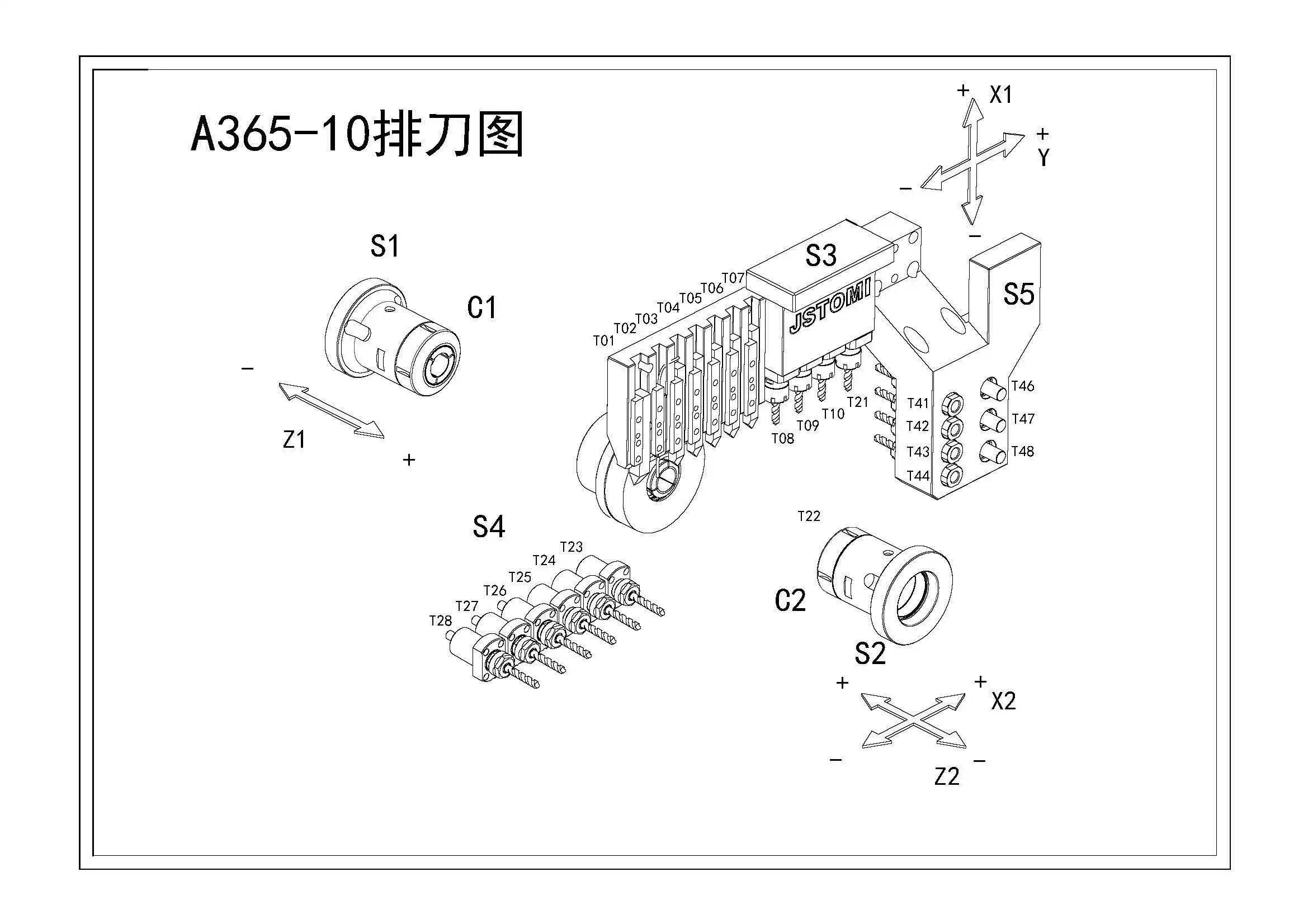

TOOLS | cutting tools | 6 tools 12*12 or 5 tool 16*16 (optional) | 6 tools 12*12 or 5 tools 16*16(optional) |

S3 lateral power tools | 5 ER16 living tool | 5 ER16 living tool | |

S3 lateral power tools Max speed. | 6000rpm | 6000rpm | |

S3 motor power | 1.0KW | 1.0KW | |

S5 end face tools | / | 5 fixed ER16+3 movavle(optional) | |

S5 max drilling diameter | / | 10mm | |

S5 Max. tapping diameter | / | M8*P1.25 | |

S5 lateral tools Max speed | / | 6000rpm | |

S5 motor power | / | 1.0KW | |

POWER | Y1 Z1 servo motor | 0.8KW | 0.8KW |

X1 servo motor | 1.3KW | 1.3KW | |

DIMENSION | Size( L x W x H ) | 1900*1300*1740mm | 1900*1300*1740mm |

N.W |

| 3450KG | 3500KG |

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. , with outstanding capability in manufacturing swiss lathe , has become a renowned enterprise in China and overseas markets.

2. The technology applied in production is relatively mature.

3. People-oriented is a corporate culture for JSWAY to advocate. Check it!