JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY slant cnc drilling machine manufacturer for plant

1. JSWAY cnc drilling machine will go through professional quality testing. It will be inspected under visual inspection, non-destructive inspection, and metallographic examination.

2. It has good strength. Its materials have the required toughness to resist deformation under stress and resist fracture due to high impact load.

3. Fast delivery methods enable Zhongshan JSTOMI CNC Machine Tool Co., Ltd. to gain a reputation in the domestic and international markets.

4. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. implements and optimizes its quality control systems.

CFG46D/CFG56D 2 axis slant bed turret CNC lathe machine for sale

Core product advantages

Machine parameter

PARAMETER | |||

|

| CFG46D | CFG56D |

CAPACITY | Spindle bore | 56MM | 66 MM |

Max. material diameter: | 45MM | 52 MM | |

Max swing over bed | 350MM | 350mm | |

Max.lenght of machining | 100MM | 100 mm | |

Max. travel of X-axis | 715MM | 715 mm | |

Max. travel of Z-axis | 280MM | 280 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

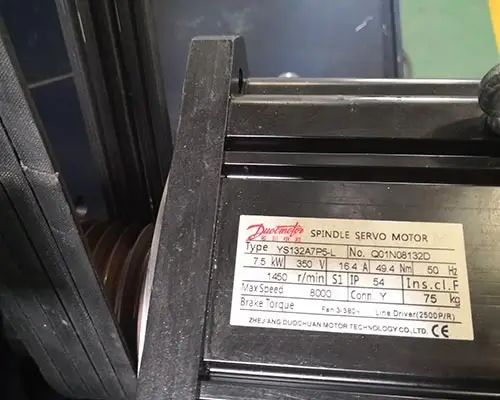

MOTOR | Servo motor | 5.5KW | 7.5KW |

Spindle speed | 4500R/MIN | 3000 rpm/min | |

X-axis servo motor | 1.3KW | 1.3KW | |

Z-axis servo motor | 1.3KW | 1.3KW | |

TOOLS | Gang type tools | 6-8 | 6-8 |

OTHERS | Total installed capacity | 9 KW | 13 KW |

Size | 2025X1385X1910 | 2025X1385X1910 | |

N.W. | 2700KG | 2750KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CFG46 | CFG56 | CFG46 | CFG56 | |

COLLET | 4-45mm | 4-52 | 5-100mm | 5-80mm |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-80mm |

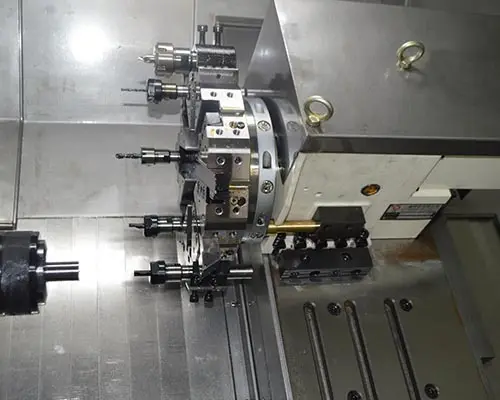

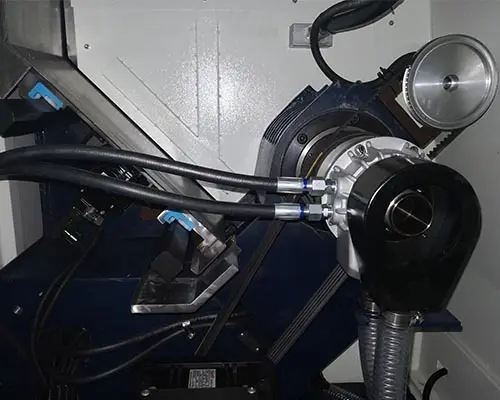

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. With years of efforts on manufacturing capstan and turret lathe , Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has been one of the most qualified manufacturers and suppliers in the industry.

2. We have employed a professional design team. With their efforts into product planning, making drawings, and sampling, they can provide a design that exactly fit our customer's needs.

3. Our company concerns very much about our environment. All of our production processes have been strict in accordance with the ISO14001 Environmental Management standard. The breadth of our mission is to reduce emissions, increase recycling, protect natural resources and harness cleaner, renewable energy sources while helping people around the world live and work in harmony with nature.

ZK5140 cnc drilling machine for high precision cutting

Main technical parameters | Unit | ZK5140C | ZK5150C |

Drilling diameter | mm | 40 | 50 |

axial thrust force | N | 16000 | 20000 |

Spindle has large output torque | Nm | 350 | 400 |

Spindle taper | Morse | 4 | 5 |

Main motor power | Kw | 3 | 4 |

Rang of spindle speed | r/min | 31.5-1400(12steps) | |

X /Y / Z fast | mm /min | 8000 /8000 /7000 | |

Spindle box up and down stroke | mm | 470(manual operation) | |

Left and right stroke (X-axis) | mm | 900 | |

Forward and backward stroke (Y-axis) | mm | 420 | |

Spindle up and down stroke (z-axis) | mm | 250(self-motion 240) | |

Distance from the end face of the spindle to the working table | mm | 0-800 | |

Bed dimension | mm | 1000x550 | |

Positioning accuracy (X, Y) | mm | 0.05(0.04) | |

Repeat positioning accuracy (X, Y) | mm | 0.02(0.015) | |

Machine weight | kg | 2700 | |

Boundary dimension | mm | 2060*2160*2550 | |

Company Information

Tengzhou North China CNC Machine Tool Co. Ltd. is a company dedicated to extreme metal cutting machine development, design, manufacturing, sales and one of the import and export rights, under the jurisdiction of the milling and drilling division division, turning division, sawing machine division, forging machine division, metal forming machine tool division.

Since the founding of the company, the company holds the "achievements of employees, development enterprises, service customers, return social" enterprise values, to create a well-known brand in the industry. The main products of the company have entered the core manufacturing fields of automobile manufacturing, national defense and military industry, aerospace, rail transportation, hardware mould and other key industries. In recent years, the company has begun to undertake domestic and foreign mechanical engineering and domestic and international bidding projects. Has to include the China Railway Group, Chinese oil, CNOOC, treatment group, BMW brilliance, FAW Group, BYD automobile, industry group, Shaanxi, Hebei iron and Steel Group and other business services.

Dedication, team, innovation "is the cultural spirit of the company." to create a famous brand in China and to build a first-class enterprise "is the goal of the company's unremitting pursuit.

Factory Equipment

All of our machines are subject to strict quality control.Especially in the production process.

The Machines like lathe machine , cnc lathe machine ,cnc milling machine , cnc turning center ,Radial drilling machines, drilling milling machines ... ... have production lines as below:

1.High strength Casting making .

2.Processing production.

3.High precision quenching process.

4.Assembling process.

5.Spray paint process.

6.And also the finished product come out

Certifications

Contact U