JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY safe Swiss-style lathe high efficiency for plant

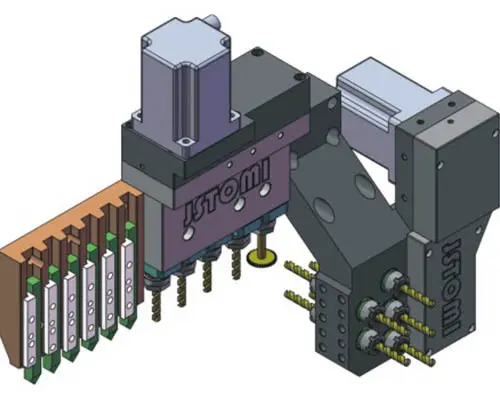

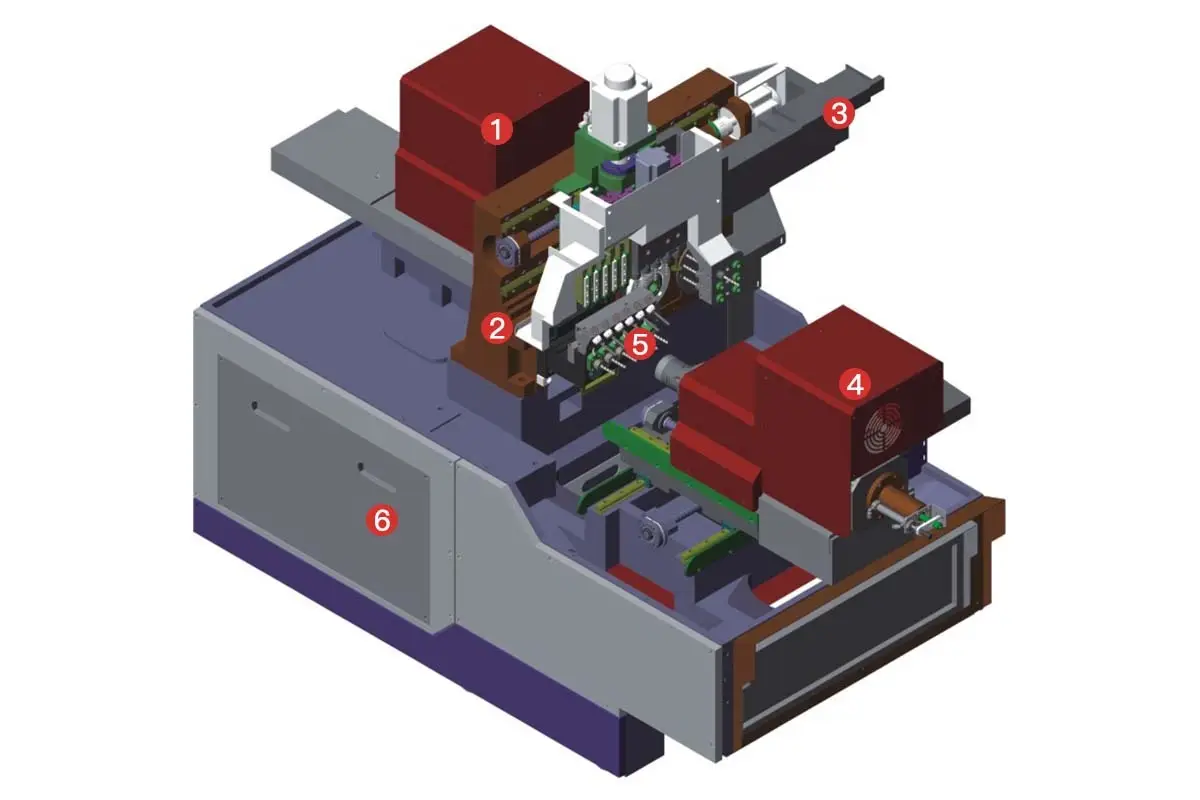

1. The development of JSWAY swiss lathe has many design considerations. They are static and dynamic stiffness, operating speed, gearbox, manual and automatic control. Each accessory of the product is self-made, ensuring its machining precision

2. The customer service policy of JSWAY results in a high degree of customer satisfication. Its parts are installed firmly, which will prevent the deflection or vibration from happening

3. Compared with other products, this product has obvious advantages, longer service life and more stable performance. It has been tested by authoritative third parties. Its cutting speed will not change even under the heavy cutting

6 aixs big bore double mechanical spindle heavy cutting Swiss type lathe machine A366

Core product advantages

Machine parameter

PARAMETER | |||

A366 | |||

CONTROLLER | System | Syntec | Syntec |

rapid speed | 36m/min(X:24m/min) | 36m/min(X:24m/min) | |

PROCESSING RANGE | spindle clamping diameter | 7-35mm | 7-35mm |

one time feeding material length | 170mm | 170mm | |

spindle max drilling diameter | 14mm | 14mm | |

spindle max tapping diameter | M8*P1.25 | M8*P1.25 | |

Max lateral drilling hole diameter | 10mm | 10mm | |

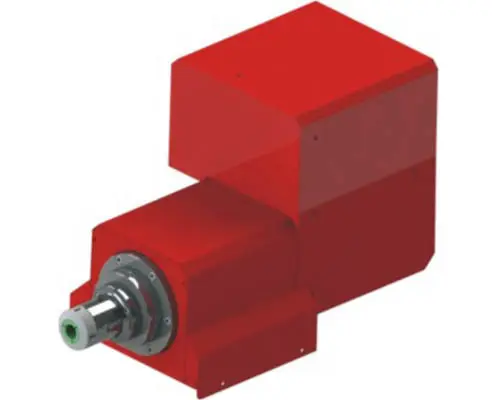

SPINDLE | S1 spindle power | 4.4KW | 4.4KW |

S1 max speed | 6000rpm | 6000rpm | |

C1 indexing | 0.015° | 0.015° | |

spindle thru hole | 36mm | 36mm | |

SPINDLE TABLE STOKE | fixed sleeve | 170mm | 170mm |

movable sleeve | 170mm | 170mm | |

TOOLS | cutting tools | 6 tools 12*12 or 5 tool 16*16 (optional) | 6 tools 12*12 or 5 tools 16*16(optional) |

S3 lateral power tools | 5 ER16 living tool | 5 ER16 living tool | |

S3 lateral power tools Max speed. | 6000rpm | 6000rpm | |

S3 motor power | 1.0KW | 1.0KW | |

S5 end face tools | / | 5 fixed ER16+3 movavle(optional) | |

S5 max drilling diameter | / | 10mm | |

S5 Max. tapping diameter | / | M8*P1.25 | |

S5 lateral tools Max speed | / | 6000rpm | |

S5 motor power | / | 1.0KW | |

POWER | Y1 Z1 servo motor | 0.8KW | 0.8KW |

X1 servo motor | 1.3KW | 1.3KW | |

DIMENSION | Size( L x W x H ) | 1900*1300*1740mm | 1900*1300*1740mm |

N.W |

| 3450KG | 3500KG |

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has employed the most innovative and expert R&D team.

2. We strive to grow even more. Our aim is to establish long-term relationships with prospective buyers. For this, we only deliver the best to gain trust in their respective markets. Get an offer!