JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY safe lathe machine company on sale for plant

1. The surface treatment of JSWAY covers several parts, including oxidization resistant treating, anodization, honing, and polishing treating. All these processes are carefully done by professional technicians. The base processed by gantry milling machine makes the product be of long service life

2. This product is available in various dimensions and patterns as per the varied requirements of clients. It is highly recommended for its wear-resistant performance

3. The product features high security. All its components are well protected by the necessary interlocking apparatus, so as to prevent components are tossed out during operation. Made by the high technology, the product meets the high international standard

4. The product has precise dimensions. All its parts sizes, form error, and position error will be measured by specific measuring tools. It will undergo a dynamic balance test to detect and correct the rotor, making it meet the requirements for use

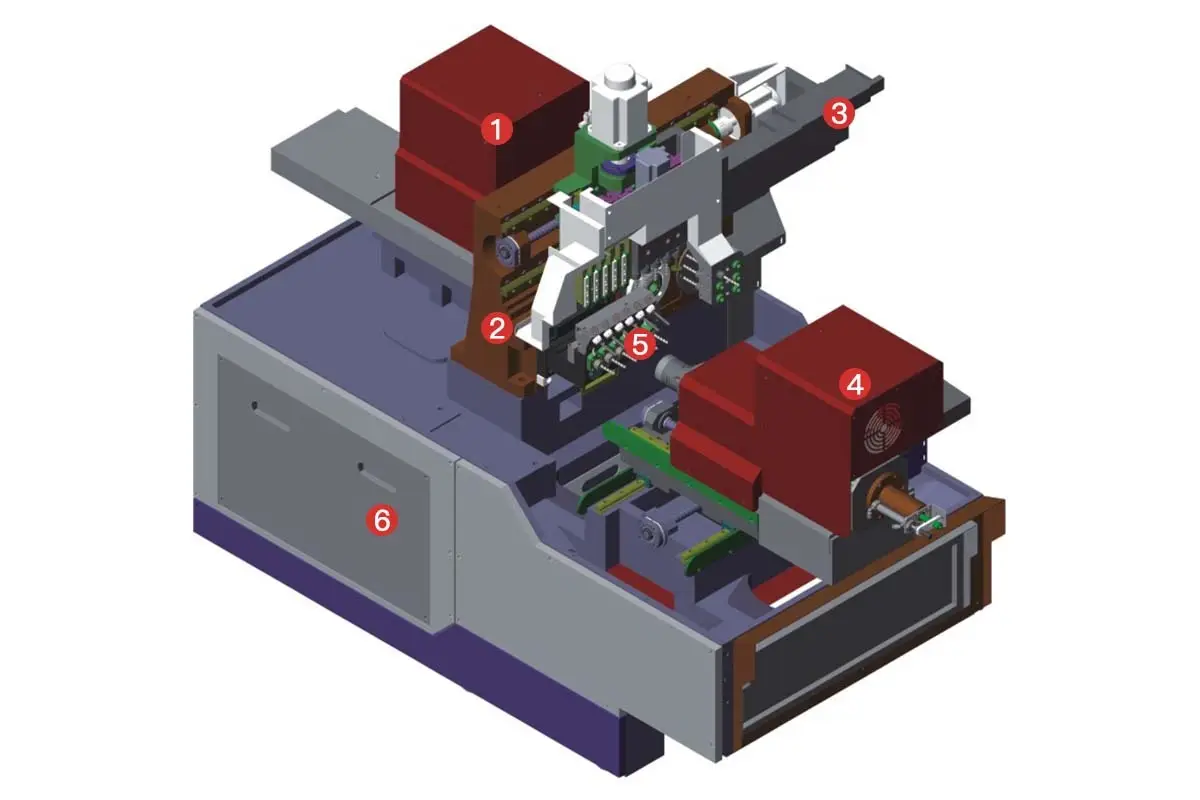

6 aixs big bore double mechanical spindle heavy cutting Swiss type lathe machine A366

Core product advantages

Machine parameter

PARAMETER | |||

A366 | |||

CONTROLLER | System | Syntec | Syntec |

rapid speed | 36m/min(X:24m/min) | 36m/min(X:24m/min) | |

PROCESSING RANGE | spindle clamping diameter | 7-35mm | 7-35mm |

one time feeding material length | 170mm | 170mm | |

spindle max drilling diameter | 14mm | 14mm | |

spindle max tapping diameter | M8*P1.25 | M8*P1.25 | |

Max lateral drilling hole diameter | 10mm | 10mm | |

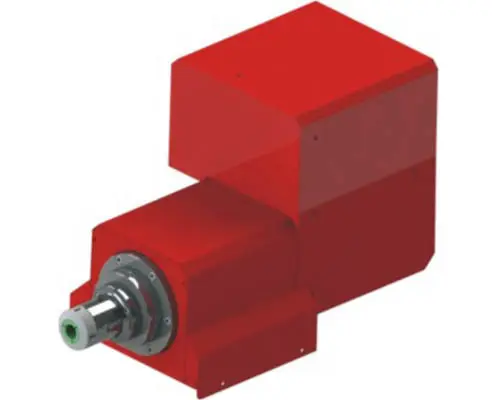

SPINDLE | S1 spindle power | 4.4KW | 4.4KW |

S1 max speed | 6000rpm | 6000rpm | |

C1 indexing | 0.015° | 0.015° | |

spindle thru hole | 36mm | 36mm | |

SPINDLE TABLE STOKE | fixed sleeve | 170mm | 170mm |

movable sleeve | 170mm | 170mm | |

TOOLS | cutting tools | 6 tools 12*12 or 5 tool 16*16 (optional) | 6 tools 12*12 or 5 tools 16*16(optional) |

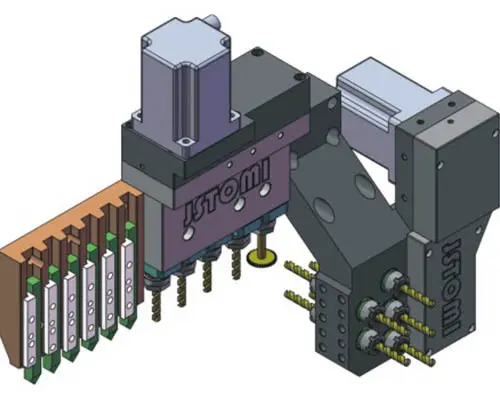

S3 lateral power tools | 5 ER16 living tool | 5 ER16 living tool | |

S3 lateral power tools Max speed. | 6000rpm | 6000rpm | |

S3 motor power | 1.0KW | 1.0KW | |

S5 end face tools | / | 5 fixed ER16+3 movavle(optional) | |

S5 max drilling diameter | / | 10mm | |

S5 Max. tapping diameter | / | M8*P1.25 | |

S5 lateral tools Max speed | / | 6000rpm | |

S5 motor power | / | 1.0KW | |

POWER | Y1 Z1 servo motor | 0.8KW | 0.8KW |

X1 servo motor | 1.3KW | 1.3KW | |

DIMENSION | Size( L x W x H ) | 1900*1300*1740mm | 1900*1300*1740mm |

N.W |

| 3450KG | 3500KG |

Company Features

1. Boasting for its high technology and strong technical force, JSWAY has gained its wide popularity for years. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. 's R&D strength and sufficient technical reserve can meet various demands of the customers.

2. We have professional QC team to guarantee lathe machine company 's quality.

3. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. currently has domestic advanced production equipment and inspection instruments. JSWAY has been committed into mountains of efforts to be a pioneer in automatic lathe industry. Check now!