JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY safe cnc lathe cost with tailstock for workplace

1. The design of JSWAY best small cnc lathe is created with care. It is defined as the use of imagination, scientific principles, and engineering techniques. The base processed by gantry milling machine makes the product be of long service life

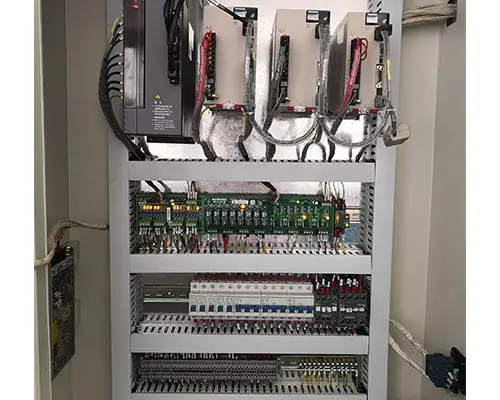

2. By following the strict standards, JSWAY controls every step to ensure the quality of cnc lathe cost . Each accessory of the product is self-made, ensuring its machining precision

3. The product is strictly tested by the quality team on a series of parameters ensuring its quality. Its interface is designed to be simple and elegant

Core product advantages

Machine parameter

PARAMETER | |||

|

| CZG46D | CZG56D |

CAPACITY | Spindle bore | 56MM | 66 MM |

Max. material diameter: | 45MM | 52 MM | |

Max swing over bed | 350MM | 350mm | |

Max.lenght of machining | 100MM | 100 mm | |

Max. travel of X-axis | 720MM | 720 mm | |

Max. travel of Z-axis | 280MM | 280 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

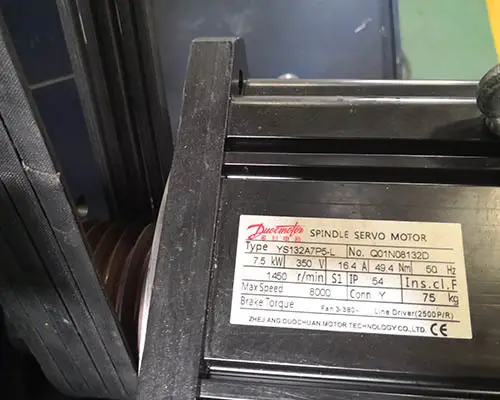

MOTOR | Servo motor | 7.5KW | 7.5KW |

Spindle speed | 4500R/MIN | 3000 rpm/min | |

X-axis servo motor | 1.3KW | 1.3KW | |

Z-axis servo motor | 1.3KW | 1.3KW | |

TOOLS | Turret | 8+3 | 8+3 |

OTHERS

| Total installed capacity | 9 KW | 13 KW |

Size | 2025X1385X1910 | 2025X1385X1910 | |

N.W. | 2700KG | 2750KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CZG46D | CZG56D | CZG46D | CZG56D | |

COLLET | 4-45mm | 4-52 | 5-100mm | 5-80mm |

CHUCK | 4-140mm | 4-160mm | 5-100mm | 5-80mm |

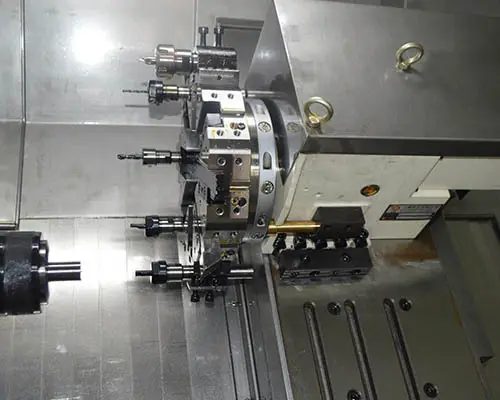

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. JSTOMI CNC Machine has formed a professional R&D team since its inception.

2. JSWAY pays high attention to after-sales service. Ask online!