JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY precision cnc vertical machining center Chinese for workplace

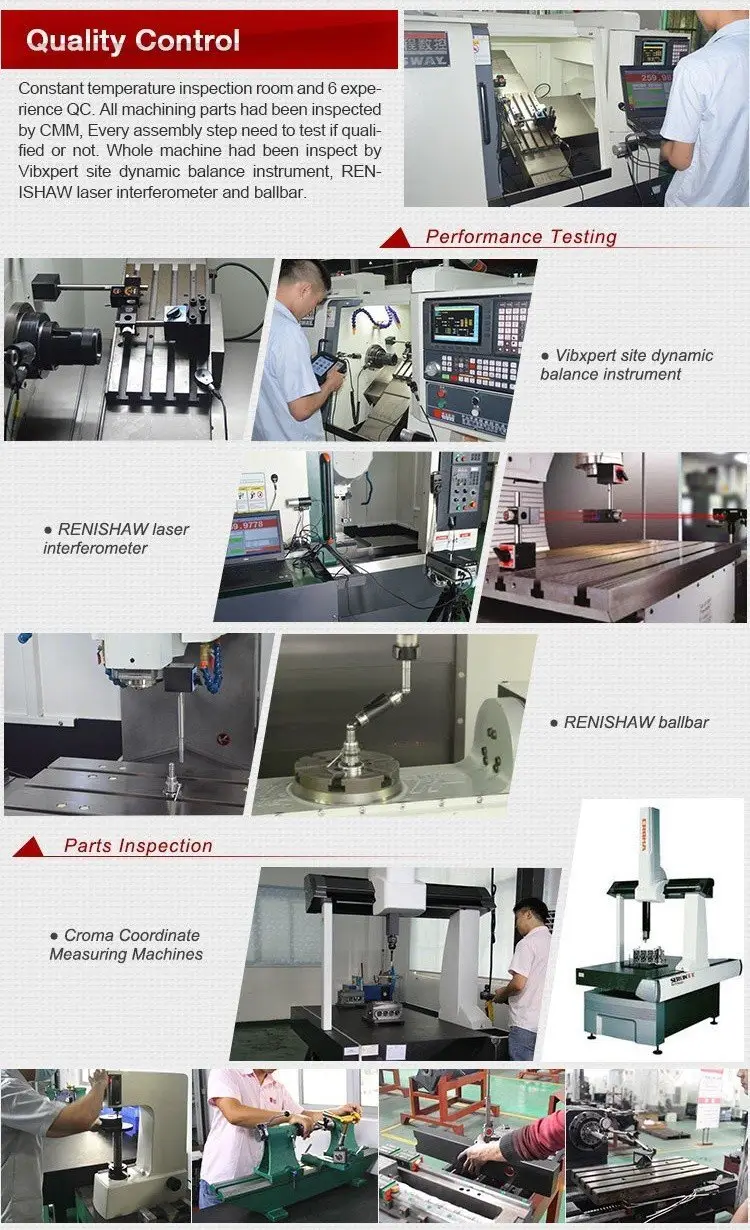

1. JSWAY lathe machine operations undergoes necessary inspection in the independent laboratory. It is scrutinized with the help of complete checking equipment to ensure it fits perfectly with the phones.

2. The advanced technology in procession with universal quality norms makes this product of high quality.

3. The product has earned good reputation and trust from clients at home and abroad.

4. With many advantages, the product has earned a good reputation in the market and has extensive market potential.

2 Axis Slant Bed Horizontal Type And New Condition Super

Precision Lathes

Feature of 2 axis cnc lathe machine tool CFG36

1,Z axis with lead screw of 40mm, powerful and high speed.

2.Whole protection inside the machine with bigger space, waterproof and bits proof

3.High machining speed up to 6000R/M, extremely smooth finish

4,High accuracy machining, stay almost the same accuracy both cold or heat machine

5,Up to 36M/min machining length

Parameter for 2 axis cnc lathe machine tool CFG36

CFG36 | ||

NC | TAIWAN /CHINA | LNC/SYNTEC/GSK |

Spindle | TAIWAN POSA | A2-5/46 |

Servo motor | YASKAWA | 0.85KW |

Spindle motor/spindle servo motor | SHANGHAI SFC | 4.0KW/5.5KW |

Frequency converter/frequency driver | MEGMEET | 5.5KW/7.5KW |

Lead screw | HIWIN/PMI | C3,PⅡ level |

Bearing | NSK,FAG | P4 level |

Lead screw coupler | MADE IN GERMEN | high precision level |

parameter | ||

Capacity | Spindle bore | 56MM |

Max.meterial diameter | 45MM | |

Max machining diameter | 350MM | |

Max.lenght of machining | 200MM | |

Max. travel of X-axis | 720MM | |

Max. travel of Z-axis | 280MM | |

X-axis/Z fast moving | 40 M/MIN | |

Reposition accuracy | 0.005MM | |

Motor | Frequency converter/Servo motor | 4.0KW/5.5KW |

Spindle speed | 5000R/MIN | |

X-axis servo motor | 0.85KW | |

Z-axis servo motor | 0.85KW | |

Tools | Gang type tools | 6--9 |

Living tools | NO | |

Others | Total installed capacity | 6KW |

Size (mm) | 2025X1385X1910 | |

N.W. | 2700KG |

Our Service

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in front

in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements

of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools

on table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,We can also

according to your need to change the configuration. Thus pls provide us your machining drawing,

we are very glad to design a specific process solution for you and recommend you a proper cnc

machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and strong

machine tool research and development capability. We are very willing to offer you customized

highly-efficient equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more quickly

and efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy all the

Equipments for your market ,at the mean time the customers can enjoy the long-term technical

advisory services in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements

of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term

service to out customers.

Welcome to contact us if need any more information.

Company Features

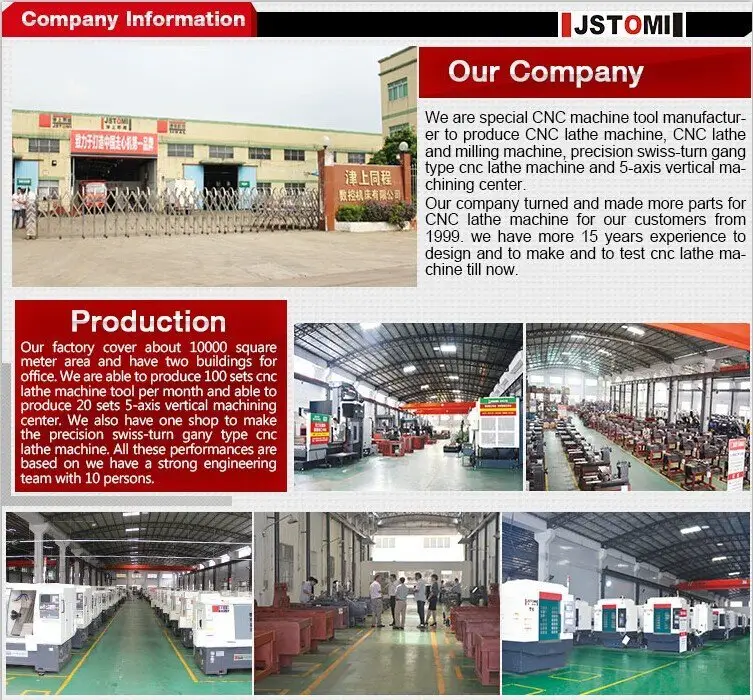

1. JSWAY has attracted more and more customers since its establishment.

2. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is proud of our technical strength.

3. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. respects customer’s culture, pays attention to customer’s experience. Contact! The satisfaction of our customers is JSWAY's ultimate goal. Contact! Zhongshan JSTOMI CNC Machine Tool Co., Ltd. 's mission to use its hard work and sweat to create greater value for customers. Contact! Innovation can be said as a responsibility for Zhongshan JSTOMI CNC Machine Tool Co., Ltd. . Contact!

The main characteristics of VMC series

The machine’s overall structure refers to the popular structure in Europe and the United States, and it’s design adopt the the famous CAD computer aided design. Meanwhile the advanced finite element algorithm is used to evaluate the structure stress effectively to ensure the structure distribution can be reasonable.

The spindle adopts the confidential spindle and special bearing, and all the screws adopt pretension process.

The vertical column and Z axle box are designed as per the strong cutting structure.

The machine adopts the imported super plastic track and hard grinding track, which ensure its great durability.

The machine adopts both full digital servo motor and a three-axis mobile servo motor which with a specification larger than the conventional power, both can truly achieve the strong cutting.

Applicable to

Hardware mold, plastic mold and other steel mold’s processing.

Technical Data Sheet

| Item No. | VMC-1060 | |

| Worktable | Table Size | 1300x600mm |

| Max. loading capacity | 600kg | |

| T-slot ( Width x No. x Distance) | 18mmx5pcsx120mm | |

| Travel | X axis Travel | 1000mm |

| Y axis Travel | 600mm | |

| Z axis Travel | 600mm | |

| Distance from spindle nose to worktable | 180-780mm | |

| Distance from spindle axis to column guideway | 600mm | |

| Spindle | Spindle Rotation Speeds | 8000R.P.M (10000/12000/15000 R.P.M) |

| Spindle Taper | BT40 | |

| Spindle motor | 11KW | |

| Three-axis motor power | 3KW | |

| Feed | X.Y.Z axis Feed Speeds | 18000mm/min |

| Accuracy | Positioning accuracy | ±0.01mm |

| Repeatability | ±0.005mm | |

| Dimension & Weight | Dimensions | 3220x2605x3090mm |

| Weight | 8500kg | |

Company Introduction

XIAMEN OSAIL TEK CO., LTD (OSAIL TEK) is a high-tech enterprise, dedicated to CNC research, development, production and sales.

With professional technical support, high performance and reliability, favorable price, stylish designs and after sales service, our machines are extensively used in various industries, such as hardware, mold carving, automotive, 3C, medical machinery, crafts industries.

“KING STEEL” is our independent brand name.

Factory

Workshop

Precision Assembly

The machine’s precision assembly is not only depends on the parts’ precision, but also depends on the assembly method. To ensure the product’s accuracy, OSAIL TEK insists on completing all the assembly 100% by ourselves, grasping every detail and each step, and refining the assembly process. Each procedure has been rigorously tested and recorded before proceeding to the next step.

First-class Processing equipment

Imported Spare Parts

The major spare parts are imported from Taiwan, Europe, America or Japan. Meanwhile, we adhere to our own technical innovation and assembly experience to ensure the products accuracy and extend the service life

Machine Tool Accessories

Machine tool accessories: abundant machine tool accessories for customer’s options to meet the processing needs of different type spare parts

Configuration Option

Cooperative partners

Company Inspection and Exhibition

Certifications

Honors

Why choose us

2. 1 Years Warranty –12months after clients receive the machine, 7*24 hours on-line professional service, free training in our workshop.

3. Honors – OSAIL TEK gains patents and certifications, ISO9001:2008 quality control system

4. Customized support—we supply special machine design based your work-pieces one by one.

5. Global service –Experienced technicians, applications skill training, on-shelf replacement parts availability, preventive maintenance programs.

6. Strong Support – Perennial cooperation with many famous companies, for example FANUC, SIEMENS and so on.

7. Other advantages-- Friendly factory price, strong research and development team.