JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY practical 3d cnc machine online for motor axial parts

1. The production of JSWAY turning lathe is constantly monitored. For example, its production is conducted in a microbiologically controlled environment. Its interface is designed to be simple and elegant

2. The product contributes a lot in employee costs. Its needs fewer workers to support its operation, which will lead to financial savings. The product can perform quick positioning

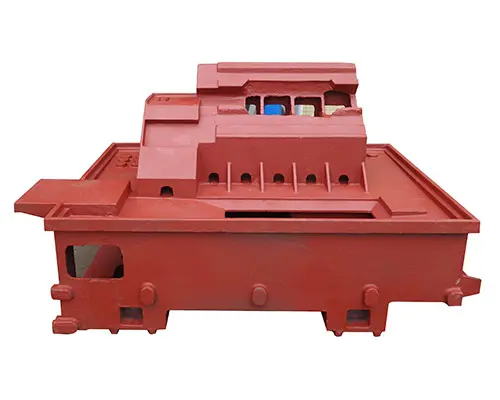

3. The product is wear-resistant, durable to use. The base processed by gantry milling machine makes the product be of long service life

4. Having been tested and modified for multiple times, the product is at its best quality. Its parts are installed firmly, which will prevent the deflection or vibration from happening

Core product advantages

Machine parameter

PARAMETER | |||

|

| CFG46X | M46X |

CAPACITY | Spindle bore | 56MM | 56 MM |

Max. material diameter: | 45MM | 45 MM | |

Max swing over bed | 280MM | 350mm | |

Max. length of machining | 100MM | 100 mm | |

Max. travel of X-axis | 720MM | 850 mm | |

Max. travel of Z-axis | 280MM | 330 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

MOTOR | Servo motor | 4.4KW | 5.9/7.5KW with magnet ring |

Spindle speed | 3000R/MIN | 5000 rpm/min | |

X-axis servo motor | 1.3KW | 1.3KW | |

Z-axis servo motor | 1.3KW | 1.3KW | |

Living tool servo motor | 0.85/1.3KW | 0.85/1.3KW | |

TOOLS | Gang type tools | 2-8 | 2-8 |

OTHERS | Total installed capacity | 12 KW | 12 KW |

Size | 2025X1385X1910 | 2180X1623X1940 | |

N.W. | 2700KG | 2950KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CFG46X | M46X | CFG46X | M46X | |

COLLET | 4-45mm | 4-45mm | 5-100mm | 5-100mm |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-100mm |

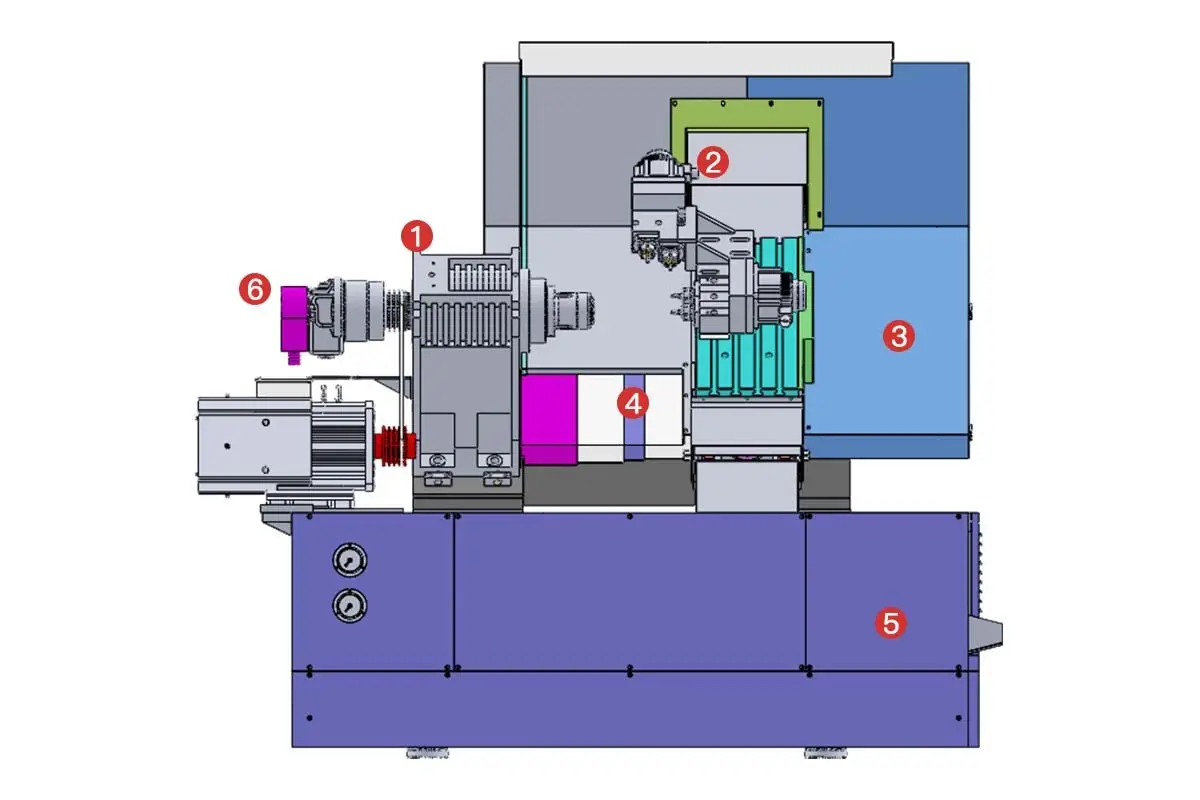

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has a high degree of professionalism in manufacturing and supplying 3d cnc machine . Our company has in-house manufacturing units. They are well-equipped with all the latest equipment and machinery to maintain a rapid rate of production.

2. We have a qualified project management team. They are able to provide a combination of development and manufacturing solutions to our clients and manage the delivery of high-quality products to customers.

3. The factory provides a full range of quality inspection solutions throughout production procedures. Inspection solutions include initial production check (IPC) for raw materials' quantity, origins, and quality, and during production inspection (DUPRO) for all workmanship and packaging. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. always prioritizes customer needs. Contact!