JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY practical 3 axis cnc high efficiency for phone parts

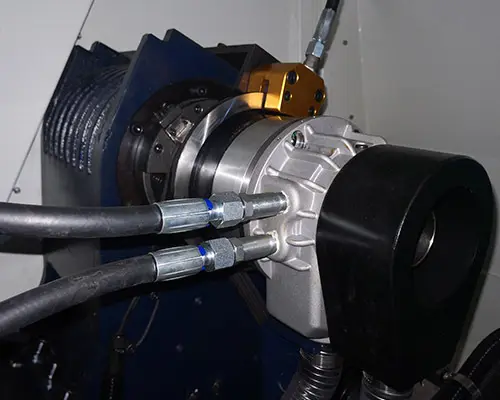

1. The tests for JSWAY turning lathe have been conducted. These tests include wiring of main control cabinets, including PLC wiring and operator stations. It is very easy to maintain, offering more convenience

2. The product has received much attention since its launch and is considered to be more successful in the future market. It can be provided with long-term technical support

3. The product has an outstanding performance to face different environment. The product has a high load-bearing capacity

4. The product undergoes quality testing from our QC team to ensure faultlessness. Before being shipped out, it will be tested and operated in process to guarantee its zero defects

5. With years of manufacturing experience, we guarantee an unparalleled level of quality of the product. It will undergo a dynamic balance test to detect and correct the rotor, making it meet the requirements for use

Core product advantages

Machine parameter

PARAMETER | ||

|

| B8D |

CAPACITY | Spindle bore | 56 MM |

Max. material diameter: | 45 MM | |

Max swing over bed | 350mm | |

Max. length of machining | 100 mm | |

Max. travel of X-axis | 630 mm | |

Max. travel of Z-axis | 300 mm | |

X/Y/Z fast moving | 36/20/36m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | |

MOTOR | Servo motor | 5.9KW with magnet ring |

Spindle speed | 5000 rpm/min | |

X-axis servo motor | 1.3KW | |

Z-axis servo motor | 1.3KW | |

Y axis servo mot0r | 850W | |

Living tool servo motor | 1.3KW | |

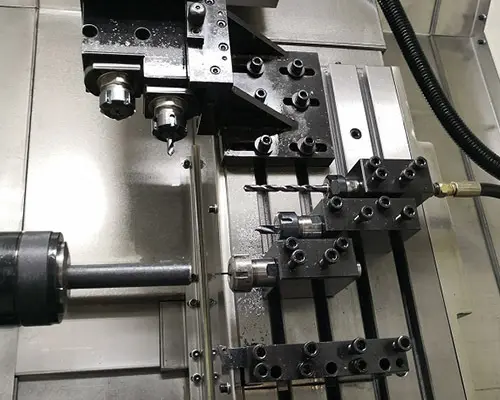

TOOLS | turret | 8/12 tools |

OTHERS

| Total installed capacity | 12 KW |

Size | 2200X1723X2023 | |

N.W. | 2950KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CFG46X | M46X | CFG46X | M46X | |

COLLET | 4-45mm | 4-45mm | 5-100mm | 5-100mm |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-100mm |

Details of the figure

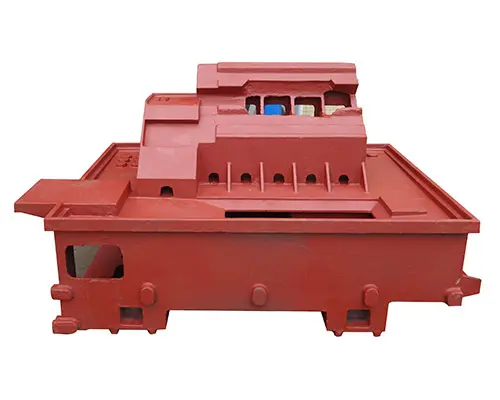

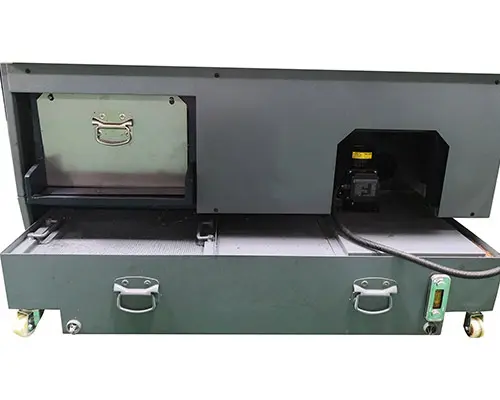

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. We have brought together a pool of R&D professionals. They have a wealth of experience and deep expertise in turning ideas into real products. They are able to offer one-stop services from the development stage to the product upgrade stage.

2. Our mission is to create more value for our customers and consumers, for the communities we operate in, and for the company – while reducing our environmental footprint at the same time.