JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY milling 4 axis cnc mill high efficiency for motor axial parts

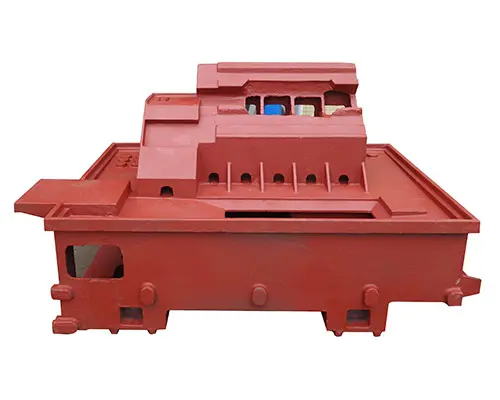

1. JSWAY 4 axis cnc lathe is finely designed. Its design is finished by considering many factors such as frame construction, control system design, mechanism design, and operating temperatures. With a full protective cover, it can prevent the water from flowing into it

2. The product meets the requirements of customers and has broad market potential. The product is produced with a superior dynamic function

3. The product has stable performance and long service life which our customers are greatly satisfied with. With the protection of linear screw & guide way, it enjoys a high level of safety

4. There is newly developed function for 4 axis cnc mill and will bring better user experience. The product can be produced in large quantities in a short time

Core product advantages

Machine parameter

PARAMETER | |||

|

| CFG46X | M46X |

CAPACITY | Spindle bore | 56MM | 56 MM |

Max. material diameter: | 45MM | 45 MM | |

Max swing over bed | 280MM | 350mm | |

Max. length of machining | 100MM | 100 mm | |

Max. travel of X-axis | 720MM | 850 mm | |

Max. travel of Z-axis | 280MM | 330 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

MOTOR | Servo motor | 4.4KW | 5.9/7.5KW with magnet ring |

Spindle speed | 3000R/MIN | 5000 rpm/min | |

X-axis servo motor | 1.3KW | 1.3KW | |

Z-axis servo motor | 1.3KW | 1.3KW | |

Living tool servo motor | 0.85/1.3KW | 0.85/1.3KW | |

TOOLS | Gang type tools | 2-8 | 2-8 |

OTHERS | Total installed capacity | 12 KW | 12 KW |

Size | 2025X1385X1910 | 2180X1623X1940 | |

N.W. | 2700KG | 2950KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CFG46X | M46X | CFG46X | M46X | |

COLLET | 4-45mm | 4-45mm | 5-100mm | 5-100mm |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-100mm |

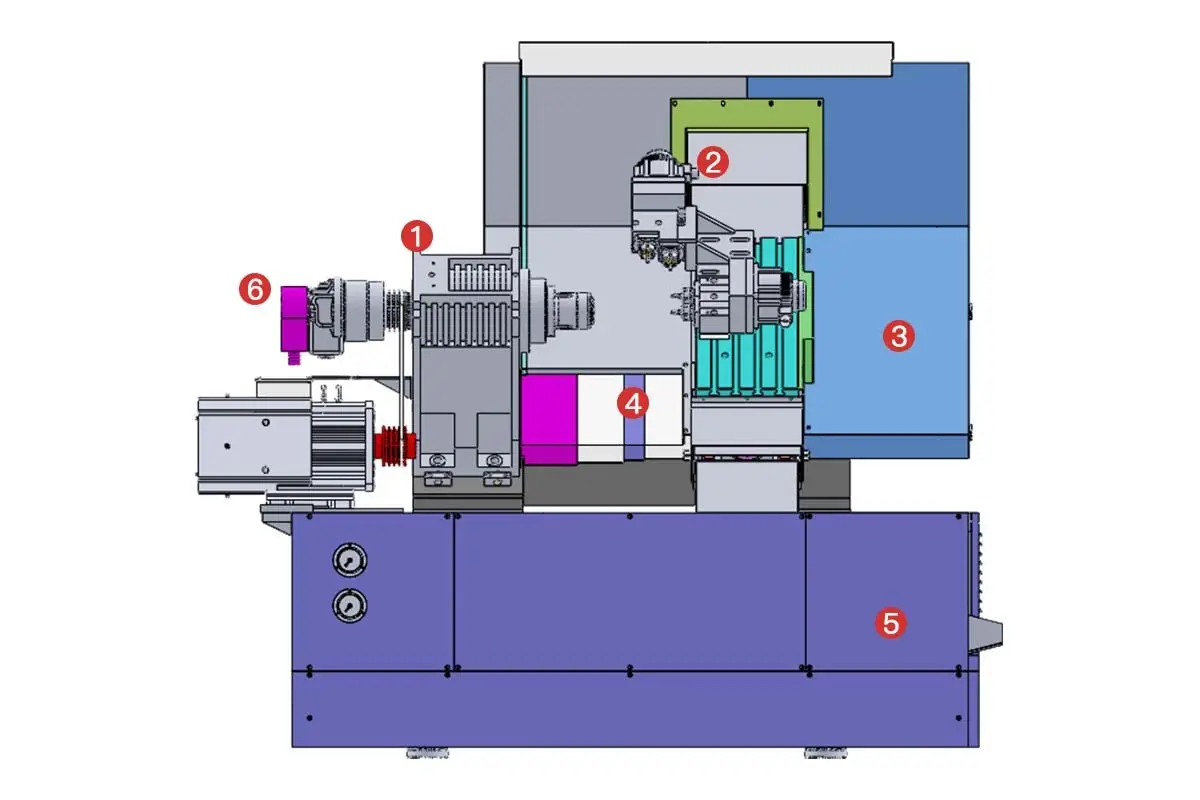

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. We have many excellent and professional R&D talents. They have strong development capabilities and a profound understanding of the product and market trends, which endows them the ability in offering rapid prototyping for customers.

2. We will seize any possible opportunity to improve and optimize our service for 4 axis cnc mill . Inquire!