JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY machine Swiss lathe machine for plant

1. JSWAY has established stable business relationship and service networks in many countries.

2. The product is highly responsive. Thanks to its advanced control system, it can respond in a short time without any delay.

3. The product is of high efficiency. It can start and finish a certain task in the shortest time without any fatigue.

4. The product is a necessary one in today's fast-paced and busy world. It will definitely help improve overall production efficiency.

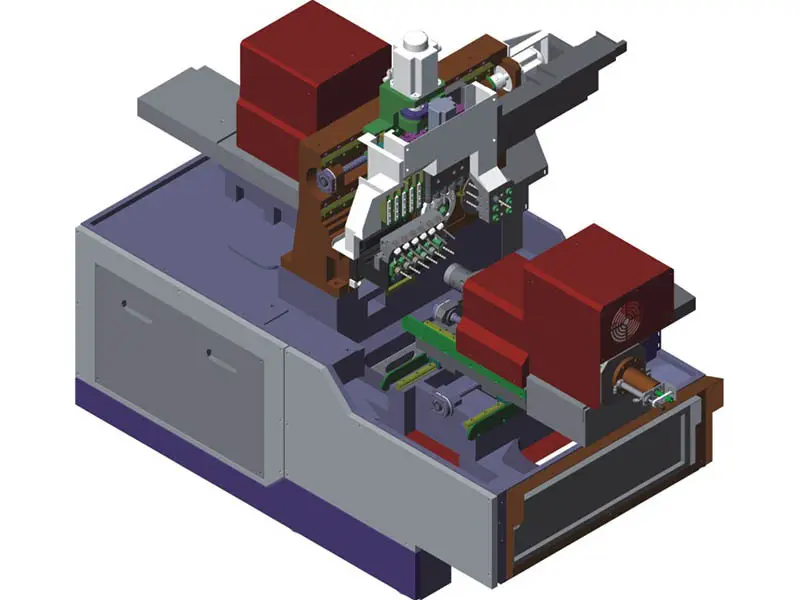

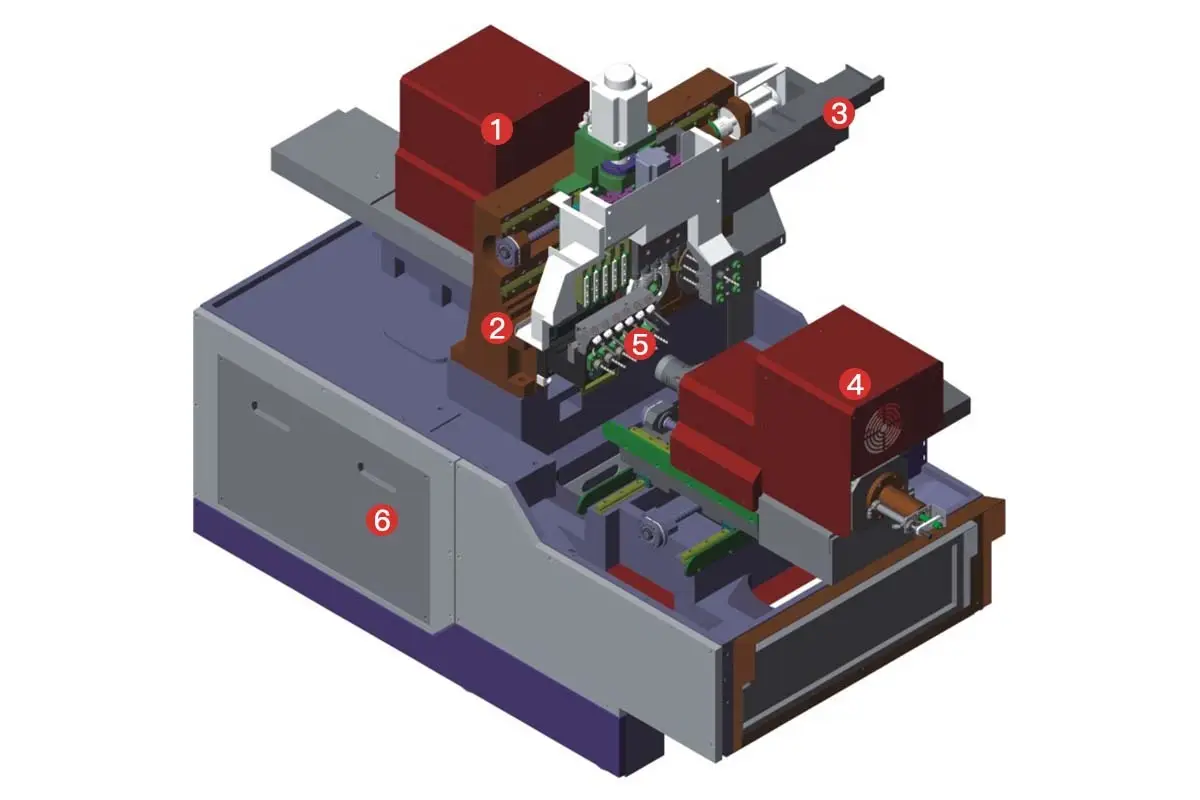

A365 twin spindle big diameter Swiss type lathe

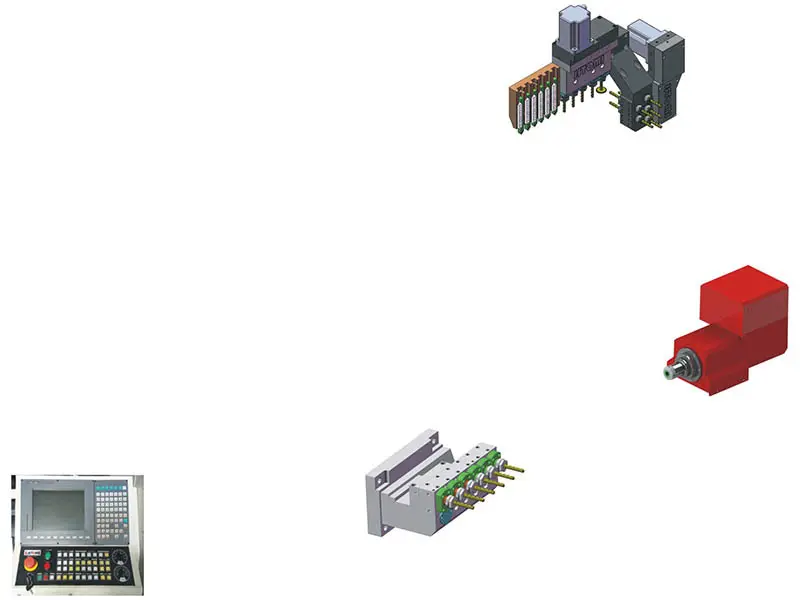

Core product advantages

Machine parameter

PARAMETER | |||

A365 A A365C | |||

CONTROLLER | System | Syntec | Syntec |

rapid speed | 36m/min(X:24m/min) | 36m/min(X:24m/min) | |

PROCESSING RANGE | spindle clamping diameter | 7-35mm | 7-35mm |

one time feeding material length | 170mm | 170mm | |

spindle max drilling diameter | 14mm | 14mm | |

spindle max tapping diameter | M8*P1.25 | M8*P1.25 | |

Max lateral drilling hole diameter | 10mm | 10mm | |

SPINDLE | S1 spindle power | 4.4KW | 4.4KW |

S1 max speed | 6000rpm | 6000rpm | |

C1 indexing | 0.015° | 0.015° | |

spindle thru hole | 36mm | 36mm | |

SPINDLE TABLE STOKE | fixed sleeve | 170mm | 170mm |

movable sleeve | 170mm | 170mm | |

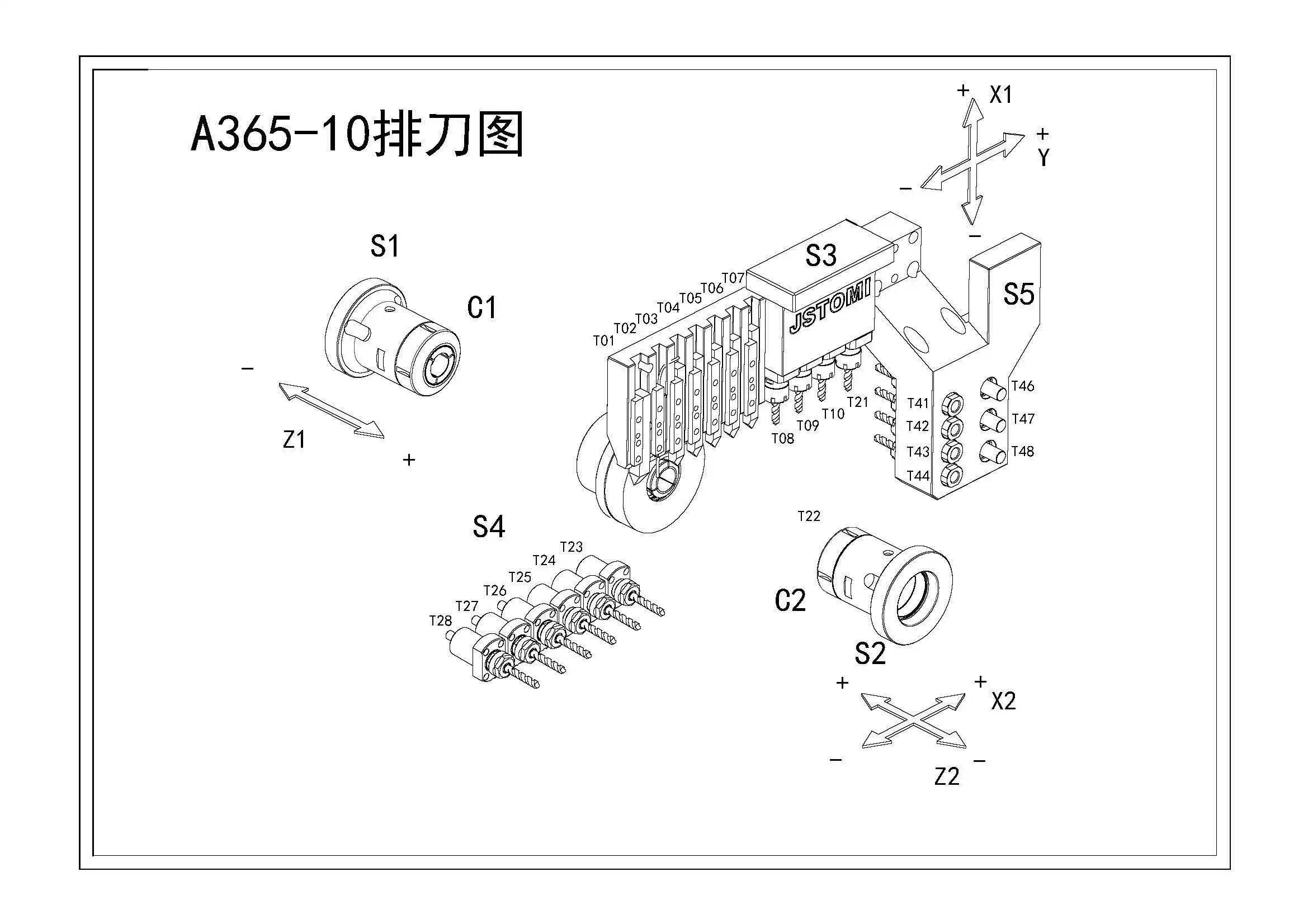

TOOLS | cutting tools | 6 tools 12*12 or 5 tool 16*16 (optional) | 6 tools 12*12 or 5 tools 16*16(optional) |

S3 lateral power tools | 5 ER16 living tool | 5 ER16 living tool | |

S3 lateral power tools Max speed. | 6000rpm | 6000rpm | |

S3 motor power | 1.0KW | 1.0KW | |

S5 end face tools | / | 5 fixed ER16+3 movavle(optional) | |

S5 max drilling diameter | / | 10mm | |

S5 Max. tapping diameter | / | M8*P1.25 | |

S5 lateral tools Max speed | / | 6000rpm | |

S5 motor power | / | 1.0KW | |

POWER | Y1 Z1 servo motor | 0.8KW | 0.8KW |

X1 servo motor | 1.3KW | 1.3KW | |

DIMENSION | Size( L x W x H ) | 1900*1300*1740mm | 1900*1300*1740mm |

N.W |

| 3450KG | 3500KG |

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has independent R&D team and mature production lines to produce Swiss lathe machine .

2. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is equipped with strong research strength, having an R&D team dedicated to developing all types of new Swiss-style lathe.

3. In the days to come, we will continue to adhere to the quality policy of “achieve innovation”. We will continue to meet the needs of our customers, continuously innovate in research and development, and focus on customized product requirements. We work to implement important strategic sustainable initiatives to reduce our environmental footprint. We search for new opportunities to improve resource efficiency and reduce production waste.