JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY lathes cnc lathe mill combo with tailstock for workplace

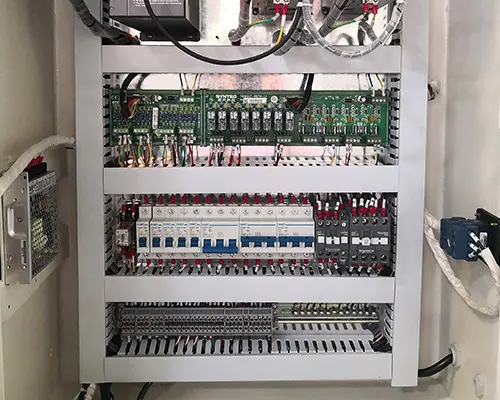

1. During the development stage of JSWAY , possible electric issues will be considered. Its electrical heating elements are developed after considering the potential overload, surge current, and static problems. Made by the high technology, the product meets the high international standard

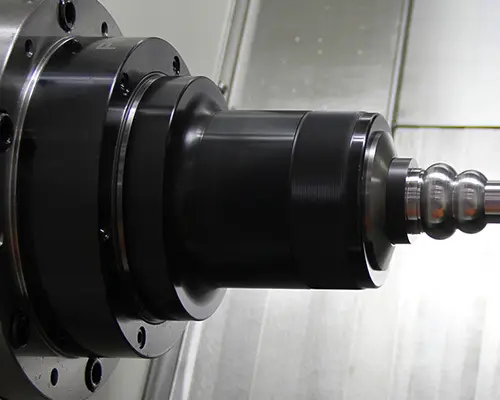

2. One of the biggest advantages in the use of this product is the considerable increase in the skill and productivity of laborers. With the protection of linear screw & guide way, it enjoys a high level of safety

3. The product has advantages of long service life and excellent performance.

Core product advantages

Machine parameter

PARAMETER | |||

CAPACITY |

| M46 | M56 |

Spindle bore | 56MM | 66 MM | |

Max. material diameter | 45MM | 52 MM | |

Max swing over bed | 350MM | 350mm | |

Max.lenght of machining | 100MM | 100 mm | |

Max. travel of X-axis | 715MM | 715 mm | |

Max. travel of Z-axis | 280MM | 280 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

MOTOR | Servo motor | 5.5KW | 7.5KW |

Spindle speed | 4500R/MIN | 3000 rpm/min | |

X-axis servo motor | 0.85KW | 1.3KW | |

Z-axis servo motor | 0.85KW | 1.3KW | |

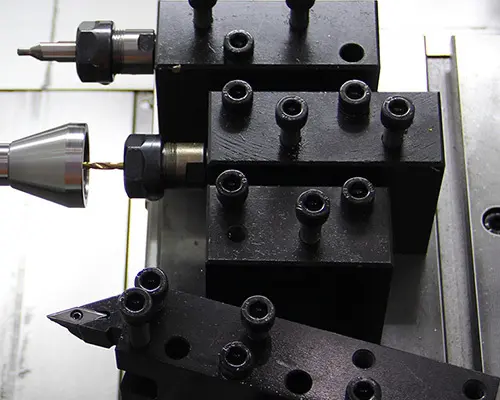

TOOLS | Gang type tools | 6-8 | 6-8 |

OTHERS | Total installed capacity | 9 KW | 13 KW |

Size | 2025X1385X1910 | 2025X1385X1910 | |

N.W. | 2700KG | 2750KG | |

MACHINING RANGE | ||||

COLLET | Diameter | Length | ||

CFG46 | CFG56 | CFG46 | CFG56 | |

4-45mm | 4-52 | 5-100mm | 5-80mm | |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-80mm |

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has become the China's largest cnc lathe mill combo enterprise and production base. We have been awarded "China Integrity Brand", "Credible Manufacturer", and "Famous Brand" at a provincial level. All these credibilities have demonstrated our ability and credibility in this industry.

2. Our company has skilled employees. They can keep our facilities in perfect running order by always being on hand to service the machinery etc. They ensure the smooth running of our production.

3. We have a team of designers. They are highly qualified and experienced. They are responsible for understanding the design needs of our customers by keeping track of the latest technology trends. We have a strong commitment to sustainable development. By utilizing the latest production technologies, we attempt to reduce emissions and increasing recycling.