JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY diameter swiss type lathe on sale for workshop

- JSTOMI adopts the strategy of the two-way interaction between enterprise and consumer. We gather timely feedback from dynamic information in the market, which enables us to provide quality services.

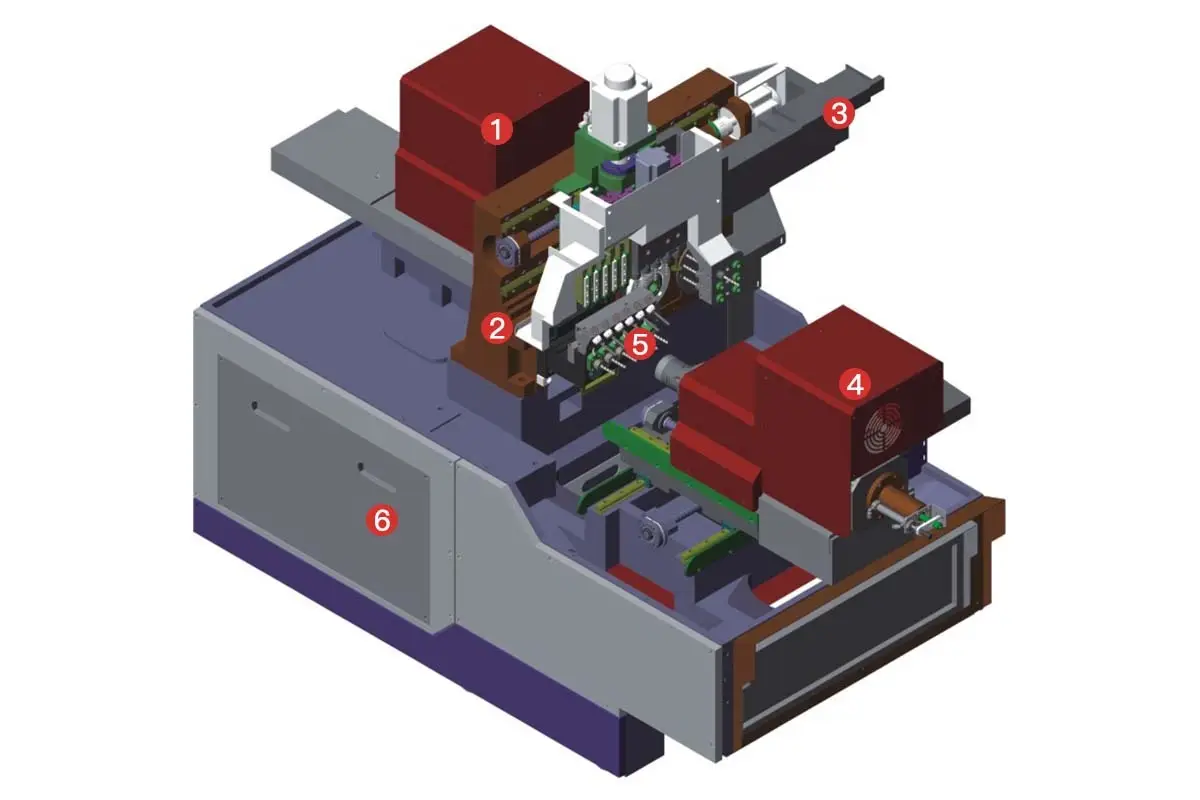

1. JSWAY high speed precision is a result of mechatronics. It is developed, designed, and manufactured on the basis of machine body, microelectronic device, sensor, and actuator technologies.

2. swiss type lathe are recognized for their merits of high speed precision .

3. swiss type lathe featured high speed precision when compared with other similar cnc swiss machine .

4. The product helps create a safer working environment for employees. It greatly reduces the risks of getting injured thanks to its automation.

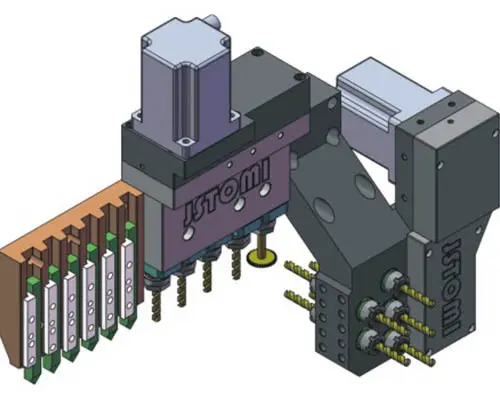

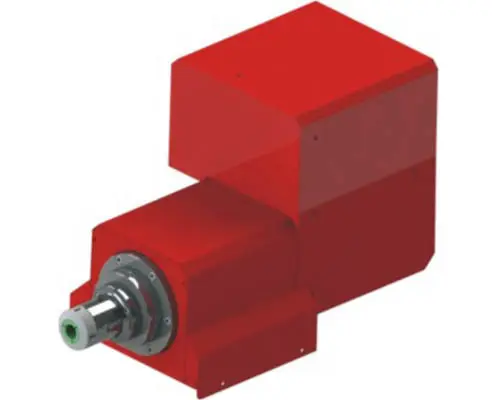

6 aixs big bore double mechanical spindle heavy cutting Swiss type lathe machine A366

Core product advantages

Machine parameter

PARAMETER | |||

A366 | |||

CONTROLLER | System | Syntec | Syntec |

rapid speed | 36m/min(X:24m/min) | 36m/min(X:24m/min) | |

PROCESSING RANGE | spindle clamping diameter | 7-35mm | 7-35mm |

one time feeding material length | 170mm | 170mm | |

spindle max drilling diameter | 14mm | 14mm | |

spindle max tapping diameter | M8*P1.25 | M8*P1.25 | |

Max lateral drilling hole diameter | 10mm | 10mm | |

SPINDLE | S1 spindle power | 4.4KW | 4.4KW |

S1 max speed | 6000rpm | 6000rpm | |

C1 indexing | 0.015° | 0.015° | |

spindle thru hole | 36mm | 36mm | |

SPINDLE TABLE STOKE | fixed sleeve | 170mm | 170mm |

movable sleeve | 170mm | 170mm | |

TOOLS | cutting tools | 6 tools 12*12 or 5 tool 16*16 (optional) | 6 tools 12*12 or 5 tools 16*16(optional) |

S3 lateral power tools | 5 ER16 living tool | 5 ER16 living tool | |

S3 lateral power tools Max speed. | 6000rpm | 6000rpm | |

S3 motor power | 1.0KW | 1.0KW | |

S5 end face tools | / | 5 fixed ER16+3 movavle(optional) | |

S5 max drilling diameter | / | 10mm | |

S5 Max. tapping diameter | / | M8*P1.25 | |

S5 lateral tools Max speed | / | 6000rpm | |

S5 motor power | / | 1.0KW | |

POWER | Y1 Z1 servo motor | 0.8KW | 0.8KW |

X1 servo motor | 1.3KW | 1.3KW | |

DIMENSION | Size( L x W x H ) | 1900*1300*1740mm | 1900*1300*1740mm |

N.W |

| 3450KG | 3500KG |

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is one of the most competitive professional suppliers of swiss type lathe in China.

2. Our company is composed of highly qualified industrial product designers. Together, they continuously look for design approaches which can lower cost and increase production without sacrificing the quality.

3. We act responsibly to the environment. We will try to upgrade the industrial structure to achieve a balance between business development and environmental friendliness. We never stop searching for sustainable growth. We support more sustainable production patterns by reducing the environmental impact of our products. Sustainability is always a vital part of how we do business. We introduce an efficient process to reduce greenhouse gas emissions, energy consumption, solid landfill waste, and water consumption.