JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY condition cnc lathe machine tools Chinese for plant

1. During the production of JSWAY turning lathe , its quality will be inspected in a random way by a third-party authority who enjoys high reputation in the gift&crafts industry.

2. The product contains little or virtually zero preservatives. Some preservatives like parabens, dyes, or oils will not be easily present.

3. This product is important in many industries. It plays an important role in increasing labor productivity and reducing the cost of human labor.

4. Thanks to its reliability, the product reduces the risk to get injured. Employees will feel safer while they are on the job.

Core product advantages

Machine parameter

PARAMETER | |||

CAPACITY |

| M46 | M56 |

Spindle bore | 56MM | 66 MM | |

Max. material diameter | 45MM | 52 MM | |

Max swing over bed | 350MM | 350mm | |

Max.lenght of machining | 100MM | 100 mm | |

Max. travel of X-axis | 715MM | 715 mm | |

Max. travel of Z-axis | 280MM | 280 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

MOTOR | Servo motor | 5.5KW | 7.5KW |

Spindle speed | 4500R/MIN | 3000 rpm/min | |

X-axis servo motor | 0.85KW | 1.3KW | |

Z-axis servo motor | 0.85KW | 1.3KW | |

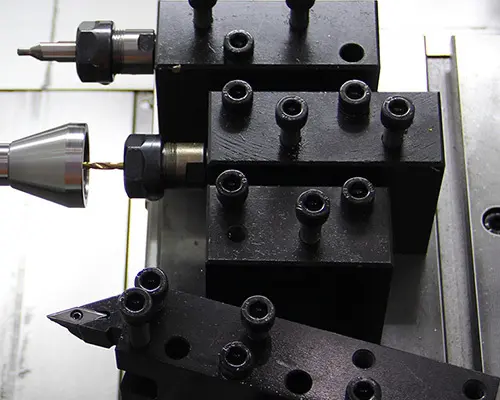

TOOLS | Gang type tools | 6-8 | 6-8 |

OTHERS | Total installed capacity | 9 KW | 13 KW |

Size | 2025X1385X1910 | 2025X1385X1910 | |

N.W. | 2700KG | 2750KG | |

MACHINING RANGE | ||||

COLLET | Diameter | Length | ||

CFG46 | CFG56 | CFG46 | CFG56 | |

4-45mm | 4-52 | 5-100mm | 5-80mm | |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-80mm |

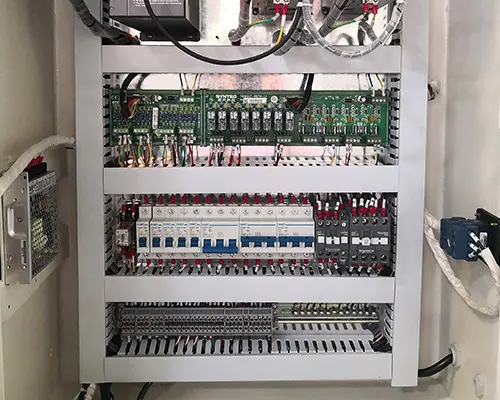

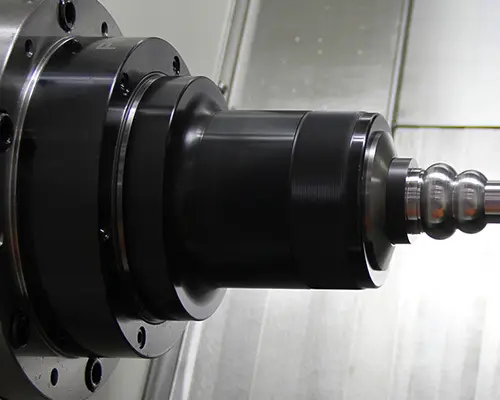

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is a one-stop cnc lathe machine tools products supplier.

2. We have set up a professional marketing team. With years of market exploration, they are able to respond rapidly to market trends and effectively analyze the customers' needs.

3. We aim to maintain strict environmental and sustainability standards throughout our production process. We achieve cost savings at various stages by cutting the costs of raw materials and reducing manufacturing expenses. We strive to continually innovate, improve, and advance manufacturing technologies and methodologies. Our goal is to provide the best results for our customers. Environment protection is the priority of our business. We undertake active measures while utilizing our technological expertise and other resources to contribute to advancement.