JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY big swiss turning center on sale for plant

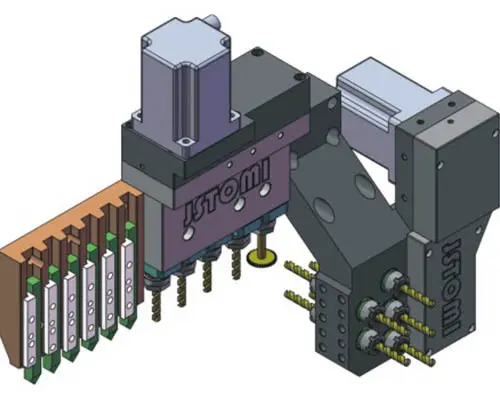

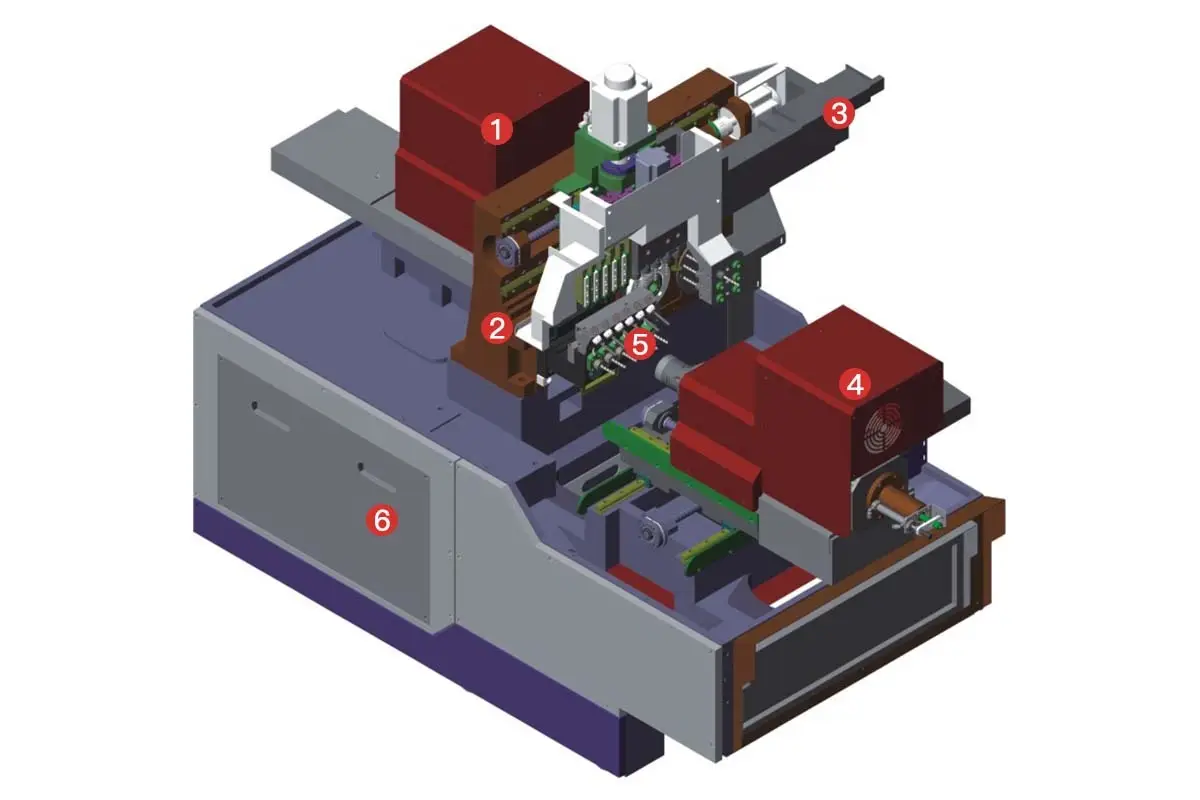

1. The design of JSWAY swiss machine is a complex process. From 3D modeling, stress on parts, to construction, every detail is well taken care of. The product has been exported to many oversea countries, like UK

2. People who live in areas where electricity is not easily accessible love this product most! It does contribute great convenience to their lives. -Said one of our customers. It can be provided with long-term technical support

3. The product has overload protection. It has a thermal relay which can withstand the impact of short circuit due to thermal inertia. Its axis runs very fast, which can guarantee the highly efficient automatic machining

4. It is not affected by the acid condition. It has passed the copper accelerated acetic acid salt spray (CASS) test which aims to check the coated one for corrosion resistance. The product can perform quick positioning

5. The product features low electricity consumption. It is manufactured adopting the energy-saving technologies which can greatly cut energy consumption. Thanks to the craftsmanship, its size will not change once it is turned on again

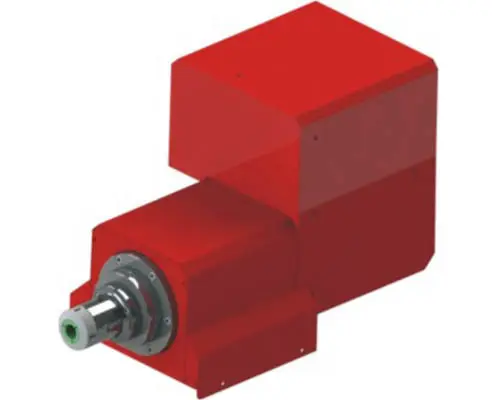

6 aixs big bore double mechanical spindle heavy cutting Swiss type lathe machine A366

Core product advantages

Machine parameter

PARAMETER | |||

A366 | |||

CONTROLLER | System | Syntec | Syntec |

rapid speed | 36m/min(X:24m/min) | 36m/min(X:24m/min) | |

PROCESSING RANGE | spindle clamping diameter | 7-35mm | 7-35mm |

one time feeding material length | 170mm | 170mm | |

spindle max drilling diameter | 14mm | 14mm | |

spindle max tapping diameter | M8*P1.25 | M8*P1.25 | |

Max lateral drilling hole diameter | 10mm | 10mm | |

SPINDLE | S1 spindle power | 4.4KW | 4.4KW |

S1 max speed | 6000rpm | 6000rpm | |

C1 indexing | 0.015° | 0.015° | |

spindle thru hole | 36mm | 36mm | |

SPINDLE TABLE STOKE | fixed sleeve | 170mm | 170mm |

movable sleeve | 170mm | 170mm | |

TOOLS | cutting tools | 6 tools 12*12 or 5 tool 16*16 (optional) | 6 tools 12*12 or 5 tools 16*16(optional) |

S3 lateral power tools | 5 ER16 living tool | 5 ER16 living tool | |

S3 lateral power tools Max speed. | 6000rpm | 6000rpm | |

S3 motor power | 1.0KW | 1.0KW | |

S5 end face tools | / | 5 fixed ER16+3 movavle(optional) | |

S5 max drilling diameter | / | 10mm | |

S5 Max. tapping diameter | / | M8*P1.25 | |

S5 lateral tools Max speed | / | 6000rpm | |

S5 motor power | / | 1.0KW | |

POWER | Y1 Z1 servo motor | 0.8KW | 0.8KW |

X1 servo motor | 1.3KW | 1.3KW | |

DIMENSION | Size( L x W x H ) | 1900*1300*1740mm | 1900*1300*1740mm |

N.W |

| 3450KG | 3500KG |

Company Features

1. We are proud of our extensive sales network. With a commercial footprint in many world markets, our key regions include the APAC regions and emerging markets in the CEE.

2. The goal of our company is to become an innovation-driven manufacturing company. Under this goal, we will put more investment in introducing high techs and pooling R&D talents.