JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY bed cnc turning center supplier for car parts

- JSTOMI receives converted recognition from customers depending on good product quality and a comprehensive service system.

1. During formation, data on the cell performance of JSWAY turning lathe such as capacity and impedance, are gathered and recorded for quality analysis and traceability.

2. turning lathe has long service life and many other technical superiorities, is especially suitable for cnc turning center field.

3. By discarding the dross and selecting the essential, our cnc turning center has been successful in its turning lathe .

4. This product meets the needs of customers domestic and foreign.

Core product advantages

Machine parameter

PARAMETER | |||

|

| CFG46X | M46X |

CAPACITY | Spindle bore | 56MM | 56 MM |

Max. material diameter: | 45MM | 45 MM | |

Max swing over bed | 280MM | 350mm | |

Max. length of machining | 100MM | 100 mm | |

Max. travel of X-axis | 720MM | 850 mm | |

Max. travel of Z-axis | 280MM | 330 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

MOTOR | Servo motor | 4.4KW | 5.9/7.5KW with magnet ring |

Spindle speed | 3000R/MIN | 5000 rpm/min | |

X-axis servo motor | 1.3KW | 1.3KW | |

Z-axis servo motor | 1.3KW | 1.3KW | |

Living tool servo motor | 0.85/1.3KW | 0.85/1.3KW | |

TOOLS | Gang type tools | 2-8 | 2-8 |

OTHERS | Total installed capacity | 12 KW | 12 KW |

Size | 2025X1385X1910 | 2180X1623X1940 | |

N.W. | 2700KG | 2950KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CFG46X | M46X | CFG46X | M46X | |

COLLET | 4-45mm | 4-45mm | 5-100mm | 5-100mm |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-100mm |

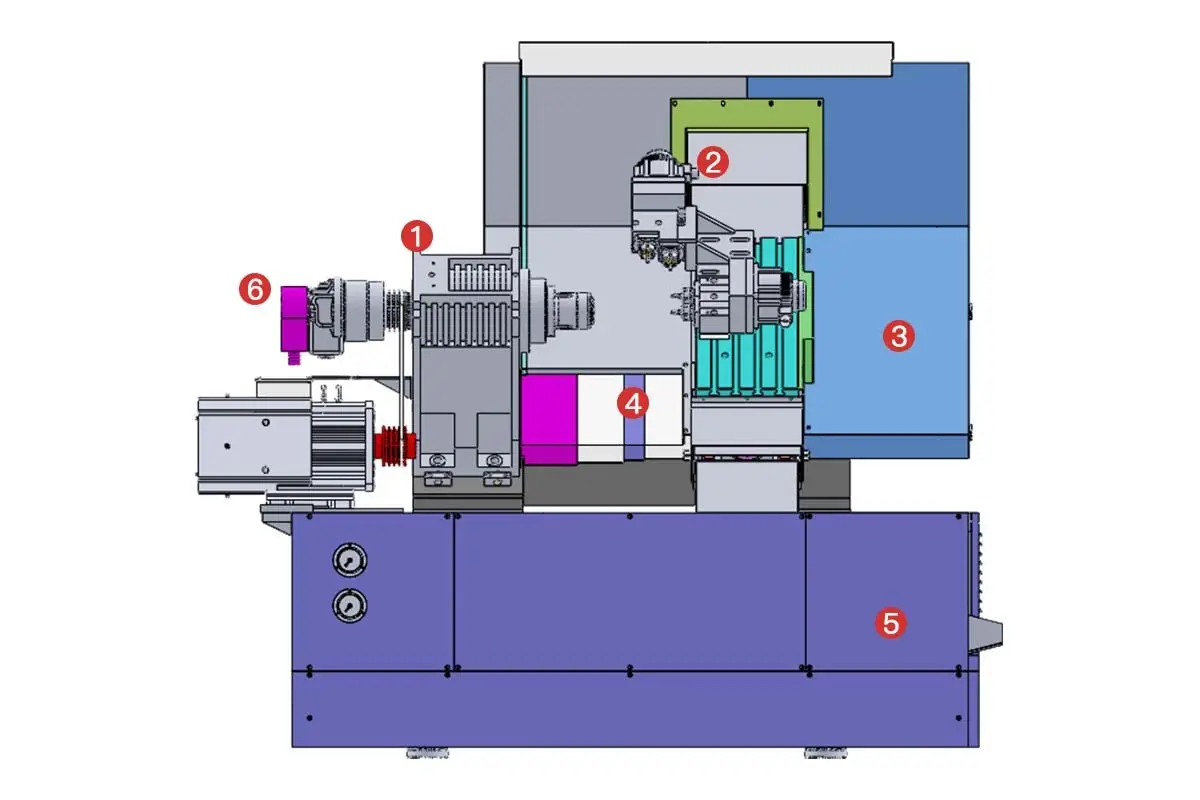

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

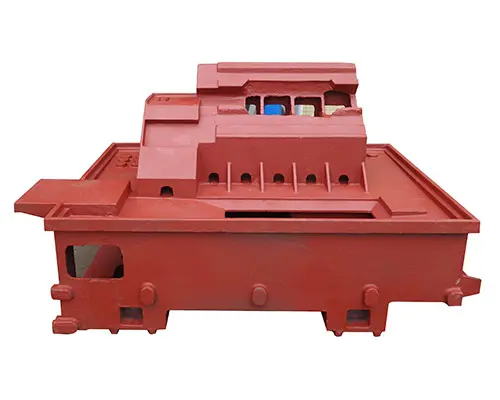

Machine dimension and packing dimension

Company Features

1. The popularity of the JSWAY brand shows strong technical strength.

2. The experienced technicians, as well as the skillful workers in our factory, are of our most cherished fortune. They always keep pace with the market trends and value customers' needs as their innovation source to help customers get the best products they actually want.

3. JSWAY firmly believes that the excellent customer service will bring unforgettable shopping experience for more customers. Inquiry! JSWAY is ambitious to be the most dominant cnc turning center supplier. Inquiry! JSWAY is looking forward to cooperating with you for our high quality 4 axis cnc machine . Inquiry!