JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY axis cnc machine for sale Chinese for plant

1. The manufactured of JSWAY slant bed lathe adopts various cutting-edge machines. They are high--speed precise CNC fabrication equipment and quality testing facilities such as height gauge and measuring instrument. The product comes with OEM service to meet customers' needs

2. The product is safe and secure for people during operation. People can rest assured that potential safety hazards are not possible to occur. The product is certified under CE and ISO 9001

3. The product is shockproof. Its static ring has excellent floatability, providing a buffering function for its parts during the mechanical movement. Its cutting speed will not change even under the heavy cutting

Core product advantages

Machine parameter

PARAMETER | ||

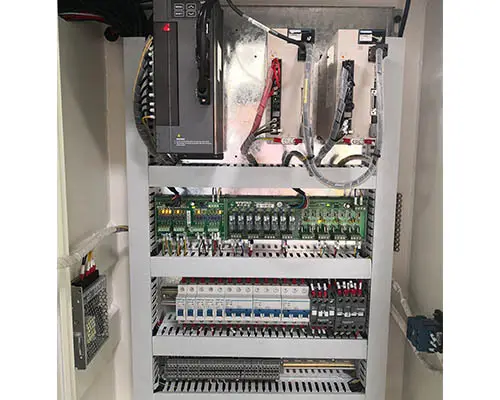

NC | TAIWAN/Germany | LNC/SYTEC/SIEMENS |

Spindle | TAIWAN POSA | A2-4/36 |

Servo motor | YASKAWA | 0.85KW |

Spindle motor | DUOC MOTOR | 3,7KW |

Frequency converter | MAGMEET | 5.5KW |

Lead screw | HIWIN/PMI | C3,PⅡlevel |

Bearing | NSK,FAG | P4 level |

Parameter |

|

|

Capacity | Spindle Bore | 46mm |

Motor | Max .Material Diameter: | 35mm |

Max Swing over bed | 280mm | |

Max.Lenght of Machining | 100mm | |

Max. Travel of X-axis | 630mm | |

Max. Travel of Z-axis | 265mm | |

X-axis/Z Fast Moving | 30m/min | |

Reposition Accuracy | 0.005mm | |

Spindle Motor | 3.7KW | |

Spindle Speed | 6000r/min | |

X-axis Servo Motor | 0.85KW | |

Z-axis Servo Motor | 0.85KW | |

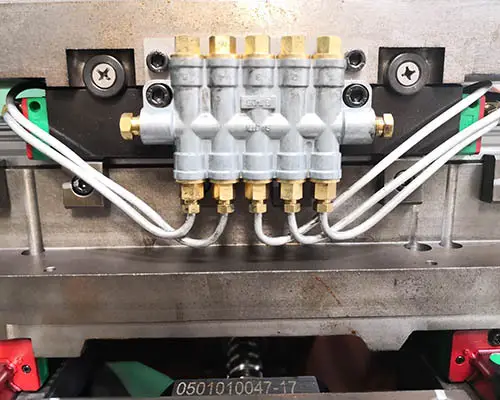

Tools | Gang Type Tools | 5—8 |

Others | Living Tools | No |

Total Installed Capacity | 7KW | |

Size | 1930X1335X1580 | |

N.W. | 2200KG | |

Machining range | ||||

| Diameter | Length | ||

Collet | 4-35mm | 5-100mm | ||

Chuck | 4-130mm | 5-100mm | ||

Details of the figure

Accessories Industry

LabelElectronic cigarette accessories

Optical parts industry

Aviation military accessories industry

Mobile phone camera accessories

Hydraulic accessories industry

Medical accessories

The application of LED industry

Application of lighting industry

The gifts

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. The utilization of slant bed lathe technology plays an important role in the production of cnc machine for sale .

2. We regularly ask our stakeholders for comment and feedback on our sustainability program. We work towards our targets over the year and monitor our progress quarterly to make sure that we are meeting them.