JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY WU800 6 Axes Interpolate Y-Axis Dual Electric Spindle Dual Upper Power Turret Machine92

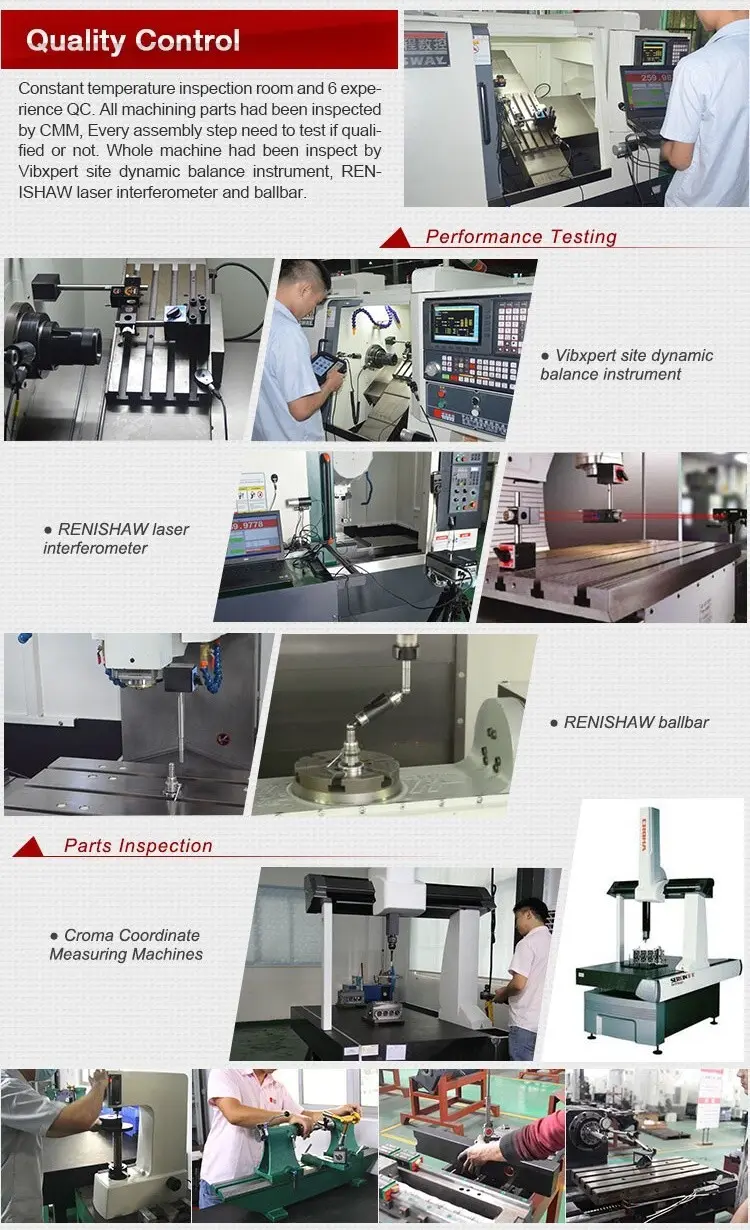

1. JSWAY will go through strict quality testings. They include structure stability testing, mechanical properties testing, materials elements inspection, and dimension accuracy.

2. Being , has a good application prospect.

3. As might be expected, have the characteristics of .

4. Increasingly, more people are using this product to update the look and enhance the aesthetic of the space in their bathrooms.

5. One of the customers said that the product offers significant savings over its lifetime since it utilizes less energy and lasts longer.

Features of 5-Axis y-axis cnc lathe machine tool CZG46Y3+2:

1. Y axis have engraving function.

2. This model is for turning, side milling and drilling.

3. Big space for machining, Z/X axis travel is long.

4. Y-axis have 3 living tool and X-axis with 2 tools; X axis can install 5-7 gang tools.

5. Japan gear, low sounds, high precision for Y axis living tool.

6. Spindle with C-axis indexing function.

7. One living power unit on front side.

Technical parameter for 5-axis y-axis cnc lathe machine tool CZG46Y3+2

| NC | TAIWAN/GUANGZHOU | LNC/SYNTEC/GSK |

| Spindle | TaiWan Posa | A2-5/46 spindle |

| X.Z axis servo motor | Japan YASKAWA | 1300 W |

| Y axis servo motor | Japan YASKAWA | 750 W |

| Spindle servo motor | Japan YASKAWA | 4.4 KW |

| Spindle servo pack | Japan YASKAWA | 5.5 KW |

| Lead screw/lead rail | TaiWan HIWIN/PMI | C3 , level two |

| Bearing | Japan NSK,Germany FAG | P4 level |

| Coupler for lead screw | From Germany | high Precision |

| Parameter | ||

| Capacity | Spindle bore | ¢56 mm |

| Max. material diameter | ¢45 mm | |

| Max. machining diameter | ¢350 mm | |

| Max. length of machining | 180 mm | |

| Max. travel of x-axis | 720 mm | |

| Max. travel of z-axis | 280 mm | |

| Max. travel of Y-axis | 100 mm | |

| Rapid speed (x-axis/z-axis) | 36 m/min | |

| Reposition accuracy | 0.005 mm | |

| Motor | Spindle servo motor | 4.4 KW |

| Spindle speed | 4000 rpm | |

| X/Z-axis servo motor | 1300 W | |

| Y-axis servo motor | 750 W | |

| Servo motor for power unit | 750 W | |

| Tools | Gang type tools | 5--8 |

| Total living power tools unit | 5 | |

| Living tool holder size | ER20/25 | |

| Other | Total power | 7KW |

| Size( L x W x H ) | 2070*1580*1870 | |

| N.W. | 2560 KGS |

Our Service

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in front in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools on table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,We can also according to your need to change the configuration. Thus pls provide us your machining drawing, we are very glad to design a specific process solution for you and recommend you a proper cnc machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and strong machine tool research and development capability. We are very willing to offer you customized highly-efficient equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more quickly and efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the long-term technical advisory services in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term service to out customers.

Welcome to contact us if need any more information.

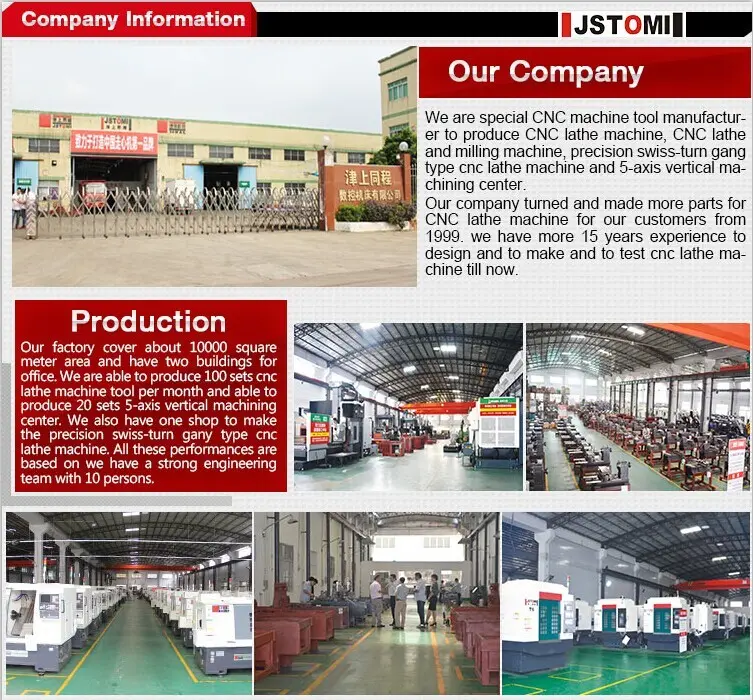

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. dominates wide maker of .

2. we have successfully developed a variety of series.

3. We always adhere to the customer-oriented concept. By using advanced production technologies and mastering the market trends, we are confident to offer customers the best product solutions. We care about the economic and environmental benefits. By introducing manufacturing facilities that are designed for environment protection, we are making efforts to execute green development, such as reducing emission reduction and energy conserving. We consider the sustainability aspect of our processes very important. We constantly review our production process to maximize our positive impacts on the environment.

transparent hot melt glue sticks production machine

1. INTRODUCTION

Stick Hot Melt Adhesive Production Line including:

1. Reactor - mixing the raw materials to get the adhesive

2. Single-screw extruder - extruding the semi-finished hot melt adhesive to the cooling system

3. Cooling tank - cooling the hot melt adhesive by circulating cold water

4. Traction stick-cutting machine - cutting the adhesive into stick by stick

(Details please consult with us online or by email!)

Additional knowledge:

1. Hot Melt Adhesive is mainly used for Diapers, Books, Shoes, etc sticking. Widely apply for Textiles, Footwear, Book wireless binding, Food packaging, Woodworking, Construction, Automotive components bonding and so on.

2. Stick Hot Melt Adhesive is widely made into 7~43mm thickness, the length are widely for 220mm, 270mm, 300mm, etc 9 type.

2. PRODUCTION PROCESS

3. PICTURES

Production line 1

Production line 2

Production line 3

Q: Can you send the formula for the products we want to make?

A: Our machines can be used for many kinds of product making, such as Resin, Paint, Adhesive, Cosmetic, Food, Chemicals. There are many kinds of these products, so it's impossible for us to know all the formulas and technologies. We can assist you to find the raw material list you need, and after you place order with us, we can help you to find formula and technology, there will be engineers to teach you how to make the product, and the cost will be on your account.

Q: Do you have machines in stock?

A: Yes, but just the small-scale machines. Machines are different with other products, most of the large-scale machines are designed according to our customers' requirements, different customers have different production requirements, so the technical parameter is different for most machines. On the other hands, most of the our machines will cover a large area, so once the machines are finished, we will effect shipment after QC.

Q: Can you send the detailed drawings of the machine to us before we place order?

A: We can send you a draft drawing of the machines, and after you place order and pay the deposit, our engineer will design the specific technical parameters fo you and send you the detailed drawings. Once you confirm without questions, we will put it into production.

Q: Why does it take at least 20 days to finish the machine?

A: Once receipt the deposit from you, we will design the drawings and make out the list of the materials and accessories for the production. Once the drawings are finished, our workers will start the production, from welding, polishing, assembling, debugging, detection and so on. After finish, they need time to check the machines, if found any possible defect parts, they will return to the production until every part is 100% approved.

Q: Can we pay the balance after we receive the machines and test without problems?

A: It's unnessary to worry about the quality of our machines, we are confident in that. After the machine is finished, we can install and test the machine for you (if you can not come to our factory, we can record a vedio and send to you). Only after you check without problems, we will effect shipment.

Q: If you price is higher than the suppliers for the products that are not made by you?

A: We can provide the whole production lines, which include many facilities and accessories(like Oil furnace, steam boiler, etc). It's impossible for us to make everyone of them, because we just make the main machines. However, based on our great reputation in the business, and also considering our huge sourcing quantity by collecting the orders from domestic and foreign customers, and our strong cash flow to pay the suppliers in advance. We can get the best offer from the suppliers. So after adding an reasonable profit for the outsourcing facilities and accessories (like Oil furnace, steam boiler, etc), we still can offer a very competitive price similar to our suppliers, or even lower in some case.

Quality assurance & Certificates

Professional Sales team & Technology support & Workshop

4. OUR CUSTOMERS

5. CONTACT US

Q:Are you factory or trading company?

A:We are the gold suppliers on Alibaba,we are ISO9001 certified factory, mainly manufacture in Forestry & Farm Machinery.

Q: What's your company advantages?

A: As the leading manufacturer of forest machines, we have exported to European market for more than ten years, familiar with forest and farm market and can recommend to clients right products.

A: we are Alibaba golden supplier, With us your money and your business is safe. We can offer 7-days refund in case of bad quality, and Alibaba trade assurance payment for safety.

Q: Can we buy one sample?

A:Yes, we need to add sample fee to the price and will return it back to your after receiving your large order in future.

Q: What's your delivery time?

A:Lead time: we have a great deal of products and spare parts in stock. On leading time we have big advantages as a manufacturer, usually in 3-5 days after order confirmation.

Q:How do you control your quality?

A:To guarantee high quality and efficient management, we have passed CE and ISO9001 quality management system certificate. All of our products are 100% inspected before shipment. Our whole manufacturing processes are under a very serious and strict system in our company.