JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY WU800 6 Axes Interpolate Y-Axis Dual Electric Spindle Dual Upper Power Turret Machine271

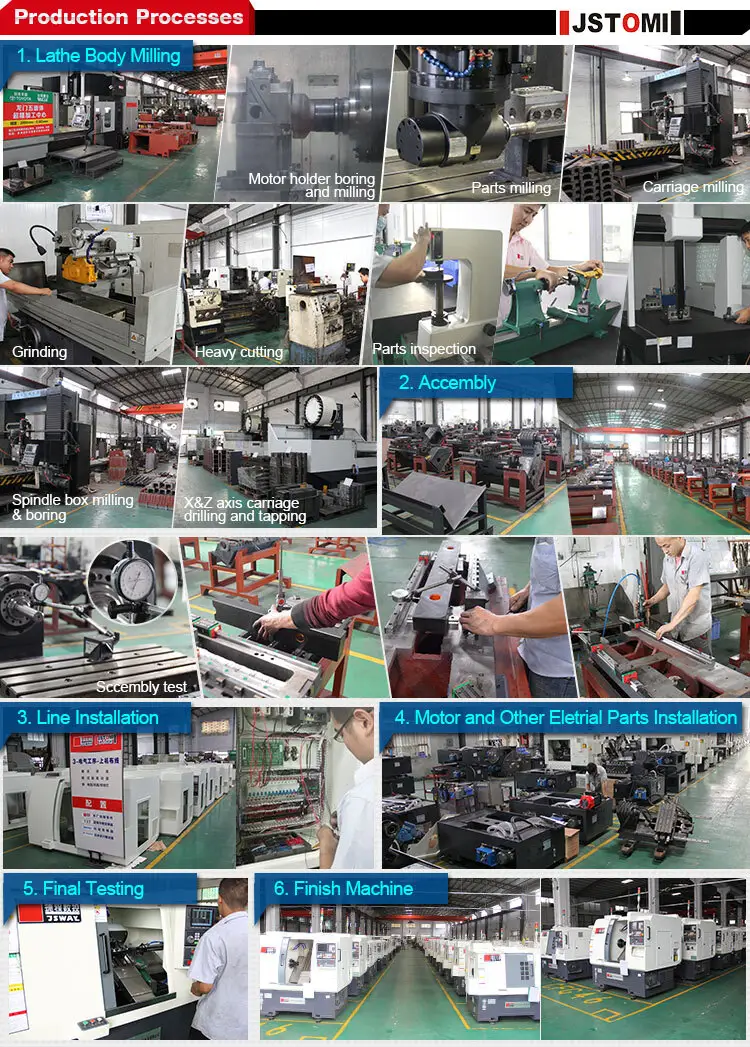

1. JSWAY has an optimized design. It uses an energy-efficient engine system, a rugged mechanical structure, and a more reasonable plc system.

2. This product has passed the inspection of our professional QC team and the authoritative third party.

3. Strict internal quality control system to ensure that products meet international standards.

4. The product is getting an increasing application in the market.

Double Spindle Rotary Auto swiss type CNC Lathe Machine Price

Features:

2. Reduce the frequency of clamping - Enhance Machining Precision

3. Reduce floor area coverage - lower production cost

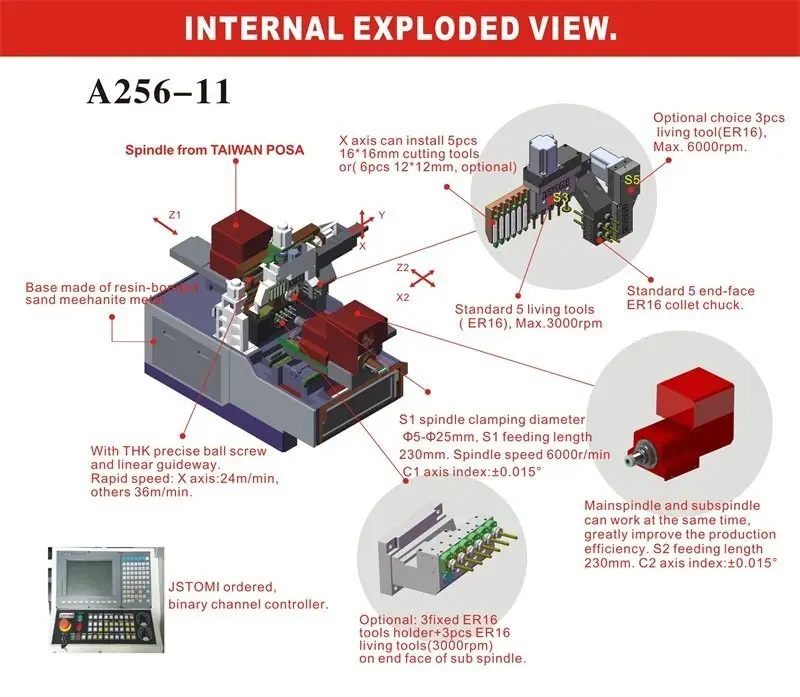

| Item | A256-11 | |

| Controller | Optional system | Syntec/Fanuc |

Processing Range | Rapid speed | 36m/min(X:24m/min) |

| S1 spindle clamping diameter | φ7-φ35mm | |

| S2 spindle clamping diameter | φ5-φ35mm | |

| S1 spindle max drilling diameter | φ20mm | |

| S1 spindle max tapping diameter | M12 | |

| Max lateral drilling hole diameter | φ10mm | |

| Spindle | S1 S2 spindle power | 4.4KW |

| S1 S2 max speed | 6000rpm | |

| C1 C2 indexing | ±0.015° | |

Spindle Table Stroke | Movable sleeve | 230mm |

| Without sleeve (optional) | S1: 280mm (without sleeve) | |

| Tools | Cutting tools (optional) | 5 tools 16*16 |

| S3 lateral power tools | 5 power tools ER20 | |

| S3 lateral power tools speed | 3000r/min | |

| S3 motor power | 1.0 KW | |

| S4 lateral power tools | 4 fixed ER16 + 4 power tools ER16 | |

| S4 lateral power tools Max speed. | 6000rpm | |

| S4 motor power | 1.0KW | |

| S5 lateral power tools | 5 fixed ER16 + 3 power tools ER16 | |

| S5 max drilling diameter | φ10mm | |

| S5 Max. tapping diameter | M8*P1.25 | |

| S5 lateral tools Max speed | 6000r/min | |

| S5 motor power | 750W | |

| Power | Y1 Z1 servo motor | 850W |

| Z2. X2. Y2 servo motor | 850W | |

| X1 servo motor | 1300W | |

| Dimension | Size( L x W x H ) | 2700*1450*1800mm |

| N.W | 3800KG |

1. We are a manufacturer of slant bed cnc lathe machine for 10 years ,Technology in the industry is come

out in front.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Our Advantages and quick delivery, Competitive price ,high quality and long term service to out

customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements

of guests.

1. What accuracy can processed work piece reach?

Machining accuracy is very complicated for it can be affected by people, machine, methods, material

and environment, and machine itself is just one of them; besides, accuracy could mean flatness,

verticality, roundness, alignment or position degrees and so on, it’s hard to make it clear in general

concept. Thus pls provide us your machining drawing, we are very glad to design a specific process

solution for you and recommend you a proper cnc machine model.

2. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools on

table.

3. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,We can also

according to your need to change the configuration. Thus pls provide us your machining drawing,

we are very glad to design a specific process solution for you and recommend you a proper cnc

machine model.

4. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and strong

machine tool research and development capability. We are very willing to offer you customized

highly-efficient equipment as long as you have certain amount of needs.

5.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more quickly

and efficiently so that can delivered safely to the designated place as guest.

6. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy all the

Equipments for your market ,at the mean time the customers can enjoy the long-term technical

advisory services in our company.

7. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements

of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term

service to out customers.

Welcome to contact us if need any more information.

Company Features

1. At present, Zhongshan JSTOMI CNC Machine Tool Co., Ltd. 's production scale and product quality of are in the domestic leading position.

2. Our team has created the architecture behind our global identity. It includes product researchers, designers, producers, and videographers. They are all intellectuals in this industry.

3. We regularly give to local non-profits and causes and support many local businesses, so that we may give back both financially as well as with our skills and our time to our society. Contact us! We manage the environmental impact of our activities with a sense of responsibility. Our staff is required to identify and apply the necessary improvements and development activities that minimize or eliminate negative environmental impact.

Product Description

Application

The production is a continuous working furnace,can complete the carburizing ,quenching and tempering heating treatment. Suitable for sheet carburizing , heating rods/bars/shafts/billets for foring and forming in forging production line.

Features

Heating is one of the most popular and best heating ways of metal material,has been widely used in fields applying oil,gas and coal heating,and is superior to oil,coal or other similar heating products by speedy heating,high efficiency and low production cost,low heating radiation,labor intensity and pollution conforming to environmental protection requipment,easily controllable temperature,small burning loss,high automatic degree that assures quality and enables production in semi-automatic and automatic machine tool and other advantages.

Advantage

work stable

safe protection

safe operation

small size

energy saving

rapid heating

| Description | Re-heating furnace |

| Brand | GEILI |

| Certificate | ISO, SGS |

| Technical | Please contact us |

Company Information

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD

was founded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.In 2001,merged with Xianyou Bangtou Mill Roll Manufacturer. In 2008,we focused on continuous casting and rolling production line equipment. In 2011,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD ,which engaged in metallurgical equipment,mainly in steel-making,continuous casting and complete rolling production line research and development,design,manufacturing, installation and general contracting services.

Main products: all kinds of specifications continuous casting machines, rolling production line equipment and various auxiliary equipment, also the spare parts. Besides, we provide technical consultant, turnkey solution and one-stop service for steel plant of deformed rebar , wire rod , angle bar, channel beam, strip and other steel related production line. The Solution was based on the customer request, such as annual capacity from 30,000 tons to over 800,000 tons, rolling speed from 3 m/s to 90 m/s.

1) Providing professional proposal of suitable production line as per customers' invest and capacity requirement

2) Providing turn-key service of designing, manufacturing, installation and commissioning for the whole production lines to meet customers requirement

3) Providing foundation layout and arrangement diagram for your plant

4) Providing technical support. We will send various technical staff to the site until the final products are meet to customers' own request.

5) Good after-sales service will be provided. Our long-term technical service will be provided if you want to adjust the production line, develop new products or improve the equipment.

6) Quality warranty will be promised.

Quality Control:

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

Finish Product QC

Ensure all the dimension and technical process are correct

Drawing QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

Packing & Shipping

As a professional and experience manufacturer in China, we can supply designing, manufacturing, installation and commissioning of the equipment with "turn-key" service.

Please send us more information about your project, we would like to give you our proposal immediately after getting your details. Sincerely welcome you to come and visit our plant.

Proffessional packaing team of oil milling machiery for overseas shipping