JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY WU800 6 Axes Interpolate Y-Axis Dual Electric Spindle Dual Upper Power Turret Machine204

- JSTOMI has insisted on the service principle to be responsible and efficient, and has established a rigorous and scientific service system to provide quality services for consumers.

1. JSWAY is manufactured under a series of steps. Its mechanical components have to be cut, welded, dried, sprayed, and so on.

2. The quality of the product is 100% guaranteed by our professional QC staff.

3. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. focus on customer production costs in order to pursue the maximization of fineness of responsibility and efficiency!

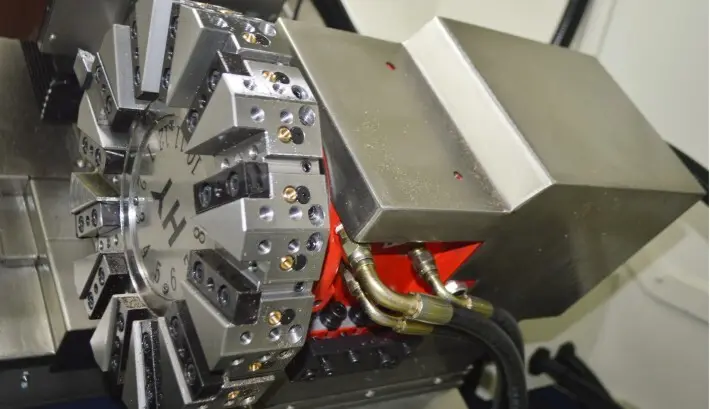

B8D automatic turning, drilling, milling and tapping combination cnc machine

Feature of B8D

1.Y-axis has engraving function.

2. This machine is for turning, side milling & drilling.

3.Y-axis has 4 lateral & endface living tools(or 5+5 optional)

4. Japan gear, low souds, high precision.

5.Max.living tool speed up to 4500rpm.

Technical parameter of cnc lathe machine tool B8D/ B10D

| Item | B6D | B8D |

controller | Optional system | Syntec/Fanuc | Syntec/Fanuc |

Spindle | Spindle bearing | NSK17016/ NSK17014 serie | NSK17016/ NSK17014 serie |

Spindle taper | Morse 6# | Morse 6# | |

Spindle nose type | A2-5 | A2-5 | |

Capacity | Spindle bore | ¢56 mm | ¢56 mm |

Max. material diameter | ¢45 mm | ¢45 mm | |

Max. machining diameter | ¢350 mm | ¢350 mm | |

Max. length of machining | 230 mm | 230 mm | |

Max. travel of x-axis | 725 mm | 725 mm | |

Max. travel of Y-axis | 340 mm | 340 mm | |

Max. travel of z-axis | 230 mm | 230 mm | |

X/Y/Z -axis fast moving | 36 /36/20mm | 36 /36/20mm | |

Positional accuracy | 7 um | 7 um | |

Reposition accuracy | 7 um | 7 um | |

Machining accuracy | 10 um | 10 um | |

Repeat machining accuracy | 10 um | 10 um | |

Motor | Spindle servo motor | JAPAN YASKAWA 4.4KW/SHENZHEN INOVANCE 5.5KW | JAPAN YASKAWA 4.4KW/SHENZHEN INOVANCE 5.5KW |

Spindle speed | 3000r/min (5000r/min) | ||

X-axis servo motor | JAPAN YASKAWA 1800W | JAPAN YASKAWA 1800W | |

Y-axis servo motor | JAPAN YASKAWA 1800W | JAPAN YASKAWA 1800W | |

Z-axis servo motor | JAPAN YASKAWA 850W | JAPAN YASKAWA 850W | |

Living tool servo motor | JAPAN YASKAWA 750W | JAPAN YASKAWA 750W | |

Tool | Turret tools | 8 | 8 |

Living tools | 3 lateral & endface living tools | 4 lateral & endface living tools | |

Others | Power unit tool holder | ER25 | ER25 |

Lubricant volume | 2L | 2L | |

Lubricant oil type | 32# | 32# | |

Hydraulic power unit volume | 70L | 70L | |

Hydraulic oil type | 46# | 46# | |

Table to spindle center height | 63mm | 63mm | |

Lathe bed | 30° slant bed | 30° slant bed | |

Total installed capacity | 4.4KW | 4.4KW | |

N.W | 3700KG | 3750KG | |

SIZE | 2400×2050×2090mm | 2400×2050×2090mm |

Detailed Images

Plumbing,Hardware,Furniture,Medical Instruments,Watch,Ornaments,E-cigarette and so on.

Our Service

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in front

in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,

2-3 tools on table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,

We can also according to your need to change the configuration. Thus pls provide us your

machining drawing, we are very glad to design a specific process solution for you and

recommend you a proper cnc machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and

strong machine tool research and development capability. We are very willing to offer you

customized highly-efficient equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more

quickly and efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy

all the Equipments for your market ,at the mean time the customers can enjoy the long-term

technical advisory services in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements

of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term service

to out customers.

Welcome to contact us if need any more information.

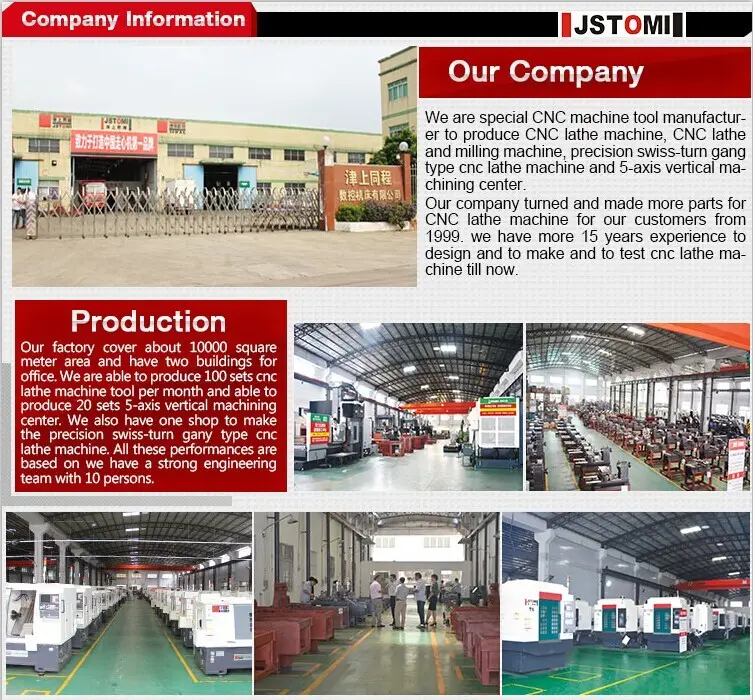

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. , a manufacturer and supplier of , has been regarded as a credible and competent market player in China.

2. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. 's technical products enjoy a high reputation among clients.

3. Customer satisfaction is the ultimate pursuit of JSTOMI CNC Machine. JSWAY has been sticking to the principle of customer first. Call now! JSWAY will do our best for each product. Call now! Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has always been committed to technology innovation and quality improvement for . Call now!

Producing Flowchart

How to make Briquettes?

Briquetting is a process where some type of raw material is compressed under high pressure to form a round or square briquette that can be used for heating purpose.

If the raw material is wood waste or agro waste, the lignin content is liberated under this very high pressure thus binding the material into a briquette with high density.

During the compression of the material, temperatures rise sufficiently to make the raw material liberate various adhesives that will assist in keeping the particles together in the compressed shape. However, to make this process successful, the moisture content of the raw material must be in the range 6 - 16 %.

The high temperature also causes the moisture in the raw material to evaporate. At a very high moisture contents, steam pockets may build up during the process thus leading to expansion which will demolish the briquette.

As the optimum moisture content for briquetting purposes varies with the raw material, we know from experience that the recommended water content is from min. 6% to max. 16%. The ideal moisture content for most wood based material is 10-12%.

Volume Reduction and Other Advantages

Briquetting often leads to a volume reduction of more than 10 times. Wood shavings will go from less than 100 kg/m3 to typical 1000 to 1100 kg/m3, which simplifies storage and transportation problems considerably.

For flammable dust, briquetting is also an effective way to reduce the risk of explosions and fires.

Generally we meet 3 types of briquetting presses:

• Mechanical Presses

• Hydraulic Presses

• Screw Presses

Features of the Briquette Machine

(1) NO binder needed during production to make clean & green fuel briquette.

(2) Quantity of heat of final product is 500-1000Kcal higher than raw material.

(3) Can replace firewood and liquefaction gas, with less investment.

(4) Small cubage and easy for transport.

Model | XNY-500A |

Capacity | 500kg/h |

Power | Total power 35kw, main power 22kw |

Diameter of briquettes | 50mm |

Density of briquettes | 1-1.4g/cm³ |

Moisture of raw material | Below 15% |

Moisture of briquettes | About 10% |

Max.size of raw material | 30mm |

Power consumption | 50KWH/ton |

Floor space | 60m² |

color | To order |

The set of production line is customized product. It can be customized according to the actual requirements of different customers.