JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY WU800 6 Axes Interpolate Y-Axis Dual Electric Spindle Dual Upper Power Turret Machine173

-

v s

1. Design result showed that the framed structure of has characters of handsome appearance.

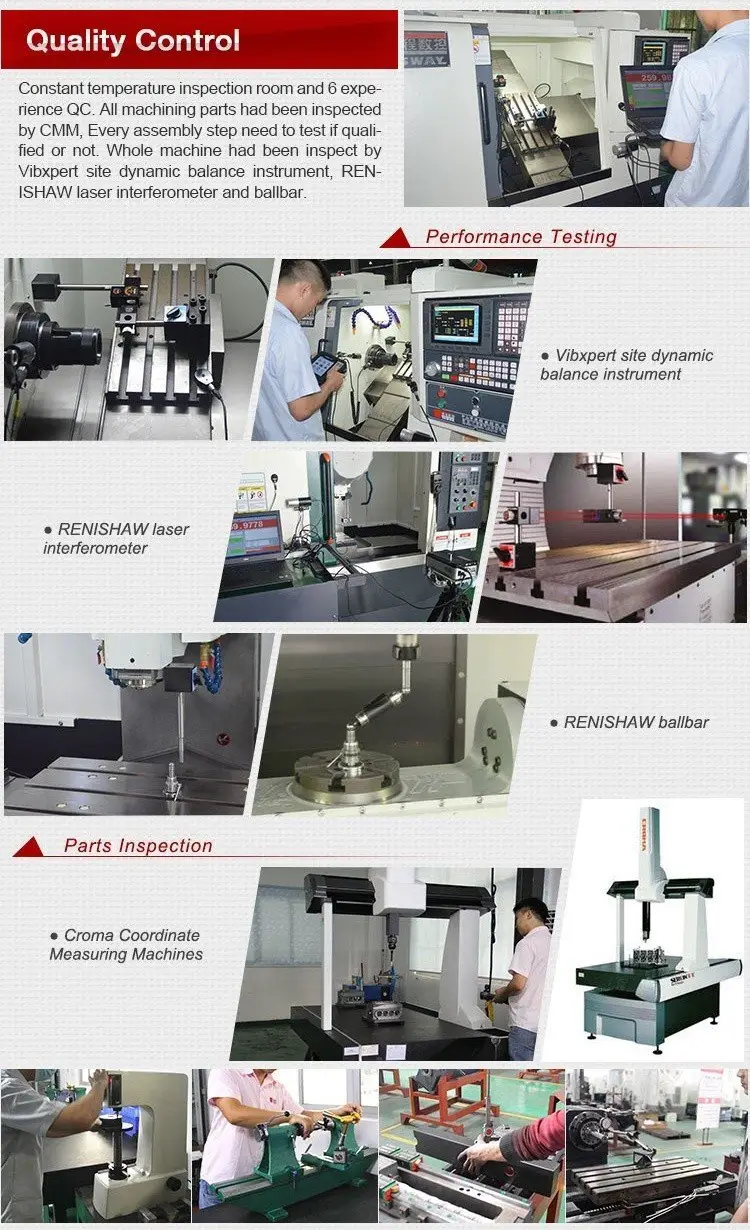

2. The high quality assurance of this product refers to the profession of our QC team.

3. This product is practical and economical and thus has been accepted by many customers.

New Horizontal Low Price Desktop Small CNC Lathe For Sale

Features of 5-axis y-axis cnc lathe machine tool CZG46Y2:

1. Y axis have engraving function.

2. This model is for turning, side milling and drilling.

3. Big space for machining, Z/X axis travel is long.

4. Y axis have 2 living tools; X axis can install 3-5 gang tools.

5. Japan gear, low sounds, high precision for Y axis living tool.

6. Spindle with C-axis indexing function.

7. living tool max speed is 4500rpm.

Technical parameter for 5-axis y-axis cnc lathe machine tool CZG46Y2;

NC | TAIWAN/GUANGZHOU | LNC/SYNTEC/GSK |

Spindle | TaiWan Posa | A2-5/46 spindle |

X.Z axis servo motor | Japan YASKAWA | 1300 W |

Y axis servo motor | Japan YASKAWA | 750W |

Spindle servo motor | Japan YASKAWA | 4.4 KW |

Spindle servo pack | Japan YASKAWA | 5.5 KW |

Lead screw/lead rail | TaiWan HIWIN/PMI | C3 , level two |

Bearing | Japan NSK,Germany FAG | P4 level |

Coupler for lead Screw | From Germany | high Precision |

Parameter | ||

Capacity | Spindle bore | ¢56 mm |

Max. material diameter | ¢45 mm | |

Max. machining diameter | ¢350 mm | |

Max. length of machining | 200 mm | |

Max. travel of x-axis | 720 mm | |

Max. travel of z-axis | 280 mm | |

Max. travel of Y-axis | 155 mm | |

Rapid speed (x-axis/z-axis) | 36/36/20 m/min | |

Reposition accuracy | 0.005 mm | |

Motor | Spindle servo motor | 4.4 KW |

Spindle speed | 3000 rpm | |

X/Z-axis servo motor | 1300 W | |

Y-axis servo motor | 750 W | |

Servo motor for power unit | 750 W | |

Tools | Gang type tools | 3--5 |

Total living power tool unit | 2 | |

Living tool holder size | ER20/25 | |

Other | Total power | 7KW |

Size( L x W x H ) | 2025*1385*1910 | |

N.W. | 2900 KGS |

Our Service

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in

front in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy

the long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements

of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools

on table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,We can

also according to your need to change the configuration. Thus pls provide us your machining

drawing, we are very glad to design a specific process solution for you and recommend you a

proper cnc machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and

strong machine tool research and development capability. We are very willing to offer you

customized highly-efficient equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more

quickly and efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy

all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the

requirements of guests.Our Advantages and quick delivery, Competitive price ,high

quality and long term service to out customers.

Welcome to contact us if need any more information.

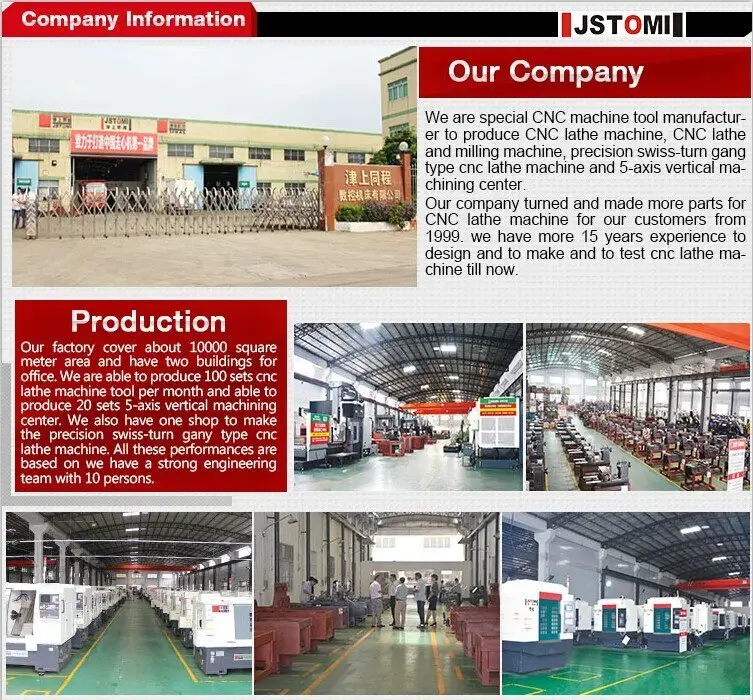

Company Features

1. Engaged in the production of for years, Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is professional and reliable.

2. JSWAY realized that the bottleneck of manufacturing needs to be broken by implementing new technology.

3. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. provide reliable scheme with . Check it! is eternal tenets that Zhongshan JSTOMI CNC Machine Tool Co., Ltd. pursue. Check it!

Earth moving machinery parts Wheel Loader part Bucket with high quality bucket tooth

The excavator bucket is a kind of bucket used to dig soil, sand, stones and other loose materials such as construction waste etc. It is made of base plate, wall plate, ear hanging plate, ear plate, teeth plate, side plate, bucket teeth, side teeth and other parts. It is a kind of working device installed on the excavator for mining work.

The bottom of the bucket is adopted with thick plate and added with the reinforcement plate. Its side plate has also been strengthened. The bucket tooth base, tooth plate and side blade plate have been adopted with high-quality wear-resistant plates, thus has strong abrasion resistance, bending capacity and long service life. It is more suitable for the working environments of digging and loading of the hard soil mixed with hard broken stone, rock, weathered granite or stone and ores after bursting, etc.

1.

2.our production site:

3. Earth moving machinery parts Wheel Loader part Bucket with high quality bucket tooth details:

4. Earth moving machinery parts Wheel Loader part Bucket with high quality bucket tooth specification:

5.Packaging & Delivery

6.Our exhibition show:

We can design and produce different products according to the customer's

requirements.

If you have any require ,pls do not hesitate to contact with me .

Our Service

1.Calling us to get telephonic advice freely, or Chatting live with us to get online help.

2."Time is gold" for you and for us, ensure providing complete equipment and it's accessories on time.

3.We have nearly 300 service peoples and have professional team for you to solvent question any time.

4.Ensure the installation and adjustment are once accepted,and provide professional design for your Project.

5.We are a 40 years old enterprise have rich experience and we can ensure providing high- quality equipments with competitive price, thit's our advantage.

6.Engineers will provide professional guidance for you and during the installation process we have professional installation team.

Our customer to visite our factory: