JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY WU800 6 Axes Interpolate Y-Axis Dual Electric Spindle Dual Upper Power Turret Machine151

-

v s

1. JSWAY become more famous mainly for its independent designs.

2. With features, has a good application prospect.

3. The exceptional performance of this product helps meet the evolving application needs.

4. It could have limitless applications with all these features.

Hard Guideway Slant Bed cnc-lathe-machine-price,CNC Automatic

Lathe,Cheap CNC Lathe Machine

Features of 5-Axis y-axis cnc lathe machine tool CZG46Y2+2:

1. Y axis have engraving function.

2. This model is for turning, side milling and drilling.

3. Big space for machining, Z/X axis travel is long.

4. Y axis and X axis have 2 living tooleach; X axis can install 3-5 gang tools.

5. Japan gear, low sounds, high precision for Y axis living tool.

6. Spindle with C-axis indexing function.

7. Base and the slanting bed is one piece.

8. living tool max speed is 4500rpm.

Technical parameter for 5-axis y-axis cnc lathe machine tool CZG46Y2+2;

NC | TAIWAN/GUANGZHOU | LNC/SYNTEC/GSK |

spindle | TaiWan Posa | A2-5/46 spindle |

X.Z axis servo motor | Japan YASKAWA | 1300 W |

Y axis servo motor | Japan YASKAWA | 750W |

spindle servo motor | Japan YASKAWA | 4.4 KW |

spindle servo pack | Japan YASKAWA | 5.5 KW |

lead screw/lead rail | TaiWan HIWIN/PMI | C3 , level two |

bearing | Japan NSK,Germany FAG | P4 level |

coupler for lead Screw | from Germany | high Precision |

Parameter | ||

Capacity | spindle bore | ¢56 mm |

Max. material diameter | ¢45 mm | |

Max. machining diameter | ¢350 mm | |

Max. length of machining | 200 mm | |

Max. travel of x-axis | 720 mm | |

Max. travel of z-axis | 280 mm | |

Max. travel of Y-axis | 155 mm | |

rapid speed (x-axis/z-axis/y -axis) | 36/36/20 m/min | |

reposition accuracy | 0.005 mm | |

Motor | spindle servo motor | 4.4 KW |

spindle speed | 3000 rpm | |

X/Z-axis servo motor | 1300 W | |

Y-axis servo motor | 750 W | |

servo motor for power unit | 750 W | |

Tools | gang type tools | 3--5 |

total living power tools unit | 4 | |

living tool holder size | ER20/25 | |

Other | total power | 7KW |

size( L x W x H ) | 2025*1385*1910 | |

N.W. | 2900 KGS |

Our Service

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in front

in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements

of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools on

table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,We can also

according to your need to change the configuration. Thus pls provide us your machining drawing,

we are very glad to design a specific process solution for you and recommend you a proper cnc

machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and strong

machine tool research and development capability. We are very willing to offer you customized

highly-efficient equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more quickly

and efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy all the

Equipments for your market ,at the mean time the customers can enjoy the long-term technical

advisory services in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements

of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term

service to out customers.

Welcome to contact us if need any more information.

Company Features

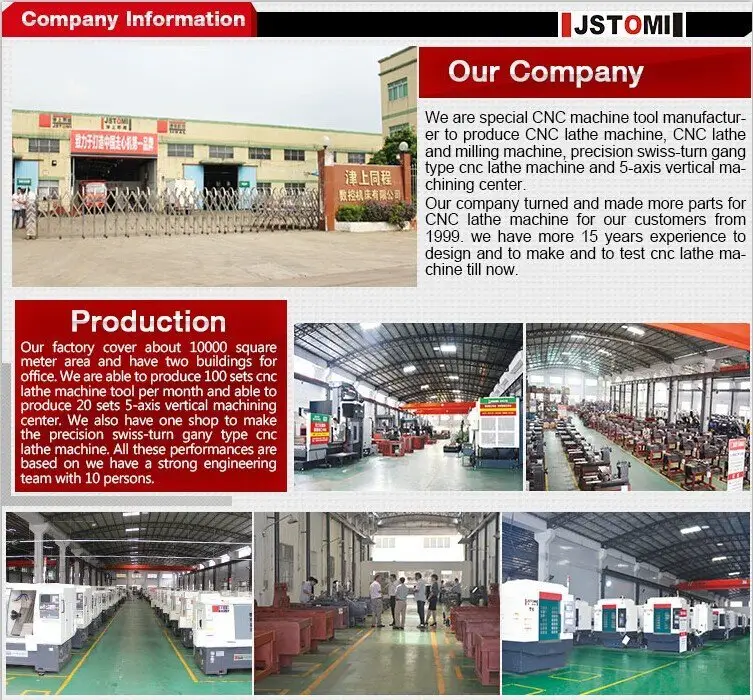

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. now plays a leading role in the industry.

2. With the unique technology and stable quality, our win a wider and wider market gradually.

3. Uphold the idea of to serve JSWAY to be the best. Get price! Taking as the fundamental value orientation is essential for JSWAY. Get price! Bearing the mission of keeps us passionate everyday. Get price!

Main Application:

Raw material is fed into the machine from the inlet and moves forward continuously along with the level of fluidizedbed under the action of vibration.The hot airpasses through fiuidi-zed-bed and carries out heat exchange with damp raw material. Then the damp air is exhausted out through cyclone separator and duster and the dry raw material is discharged through discharge outlet.

Features:

Raw material is heated evenly and heat exchange is fully used and dry capacity is high. Compared with ordinary drier, the energy can be saved about 30%.

The vibration is created by motor. It is stable in operation and convenient in maintenance, iow noise and long life;

The fluidize state is stable and no dead angle and phenomenon of broken out;

It is good in regulation and wide in suitablility. The thickness of raw material layer and movable speed inside the machine and the amplitude can be adjustde through continuos variable speed;

It is small for damaging the surface of raw material. The equipment can be used for drying raw materials that are easy broken. The drying effect can not be affected even if raw materials have anom shape;

It is effecting to prevent from cross pollution between raw material and air because the equipment adapts fully closed structure. The environment of operation is good.

Working Principle:

Pharmaceutical and chemical industries: all kinds of press tablet and granule, boric acid, borax, dihydroxybenzene, malic acid. maleic acid and so on;

Foodstuff and construction material industries: monosodium glutamate, edible sugar, edible salt, mine residue, bean, seeds and so on ;

It can also used for raw materials to add damp or cooling and so on .

Structure schematic

Technical Parameters:

Model | Area of | Temperature | Temperature | Capacity of | Vibration motor | |

Model | Power | |||||

ZLG3×0.30 | 0.9m2 | 70-140°C | 40-70°C | 20~35kg/h | ZDS31-6 | 0.8×2kw |

ZLG4.5×0.30 | 1.35m2 | 70-140°C | 40-70°C | 35~50kg/h | ZDS31-6 | 0.8×2kw |

ZLG4.5×0.45 | 2.025m2 | 70-140°C | 40-70°C | 50~70kg/h | ZDS32-6 | 1.1×2kw |

ZLG4.5×0.60 | 2.7m2 | 70-140°C | 40-70°C | 70~90kg/h | ZDS32-6 | 1.1×2kw |

ZLG6X0.45 | 2.7m2 | 70-140°C | 40-70°C | 80~100kg/h | ZDS41-6 | 1.5×2kw |

ZLG6×0.60 | 3.6m2 | 70-140°C | 40-70°C | 100~130kg/h | ZDS41-6 | 1.5×2kw |

ZLG6×0.75 | 4.5m2 | 70-140°C | 40-70°C | 120~140kg/h | ZDS42-6 | 2.2×2kw |

ZLG6×0.9 | 5.4m2 | 70-140°C | 40-70°C | 140~170kg/h | ZDS42-6 | 2.2×2kw |

ZLG7.5×6.0 | 4.5m2 | 70-140°C | 40-70°C | 130~150kg/h | ZDS42-6 | 2.2×2kw |

ZLG7.5×0.75 | 5.625m2 | 70-140°C | 40-70°C | 150~180kg/h | ZDS51-6 | 3.0×2kw |

ZLG7.5×0.9 | 6.72m2 | 70-140°C | 40-70°C | 160~210kg/h | ZDS51-6 | 3.0×2kw |

ZLG7.5×1.2 | 9m2 | 70-140°C | 40-70°C | 200~260kg/h | ZDS51-6 | 3.0×2kw |