JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY WU800 6 Axes Interpolate Y-Axis Dual Electric Spindle Dual Upper Power Turret Machine149

- Customers' needs are the foundation for JSTOMI to achieve long-term development. In order to better serve customers and further meet their needs, we run a comprehensive after-sales service system to solve their problems. We sincerely and patiently provide services including information consultation, technical training, and product maintenance and so on.

1. JSWAY is offered in various designed styles in order to meet different requirements.

2. It is recognized for strong durability and relatively long service life.

3. The product is featured by the first - class quality and stable performance.

4. The product is more competitive in the commercial market and has a promising market prospect.

5. The product meets customer's expectation and now is rather popular in the industry and has a broad market prospect.

Features of 5-axis y-axis cnc lathe machine tool CFG46Y2:

1. Y axis have engraving function.

2. This model is for turning, side milling and drilling.

3. Big space for machining, Z/X axis travel is long.

4. Y axis have 2 living tools; X axis can install 5-7 gang tools.

5. Japan gear, low sounds, high precision for Y axis living tool.

6. Spindle with C-axis indexing function.

Technical parameter for 5-axis y-axis cnc lathe machine tool CFG46Y2

| NC | TAIWAN/GUANGZHOU | LNC/SYNTEC/GSK |

| Spindle | TaiWan Posa | A2-5/46 spindle |

| X.Z axis servo motor | Japan YASKAWA | 1300 W |

| Y axis servo motor | Japan YASKAWA | 750W |

| Spindle servo motor | Japan YASKAWA | 4.4 KW |

| Spindle servo pack | Japan YASKAWA | 5.5 KW |

| Lead screw/lead rail | TaiWan HIWIN/PMI | C3 , level two |

| Bearing | Japan NSK,Germany FAG | P4 level |

| Coupler for lead Screw | From Germany | high Precision |

| Parameter | ||

| Capacity | Spindle bore | ¢56 mm |

| Max. material diameter | ¢45 mm | |

| Max. machining diameter | ¢350 mm | |

| Max. length of machining | 180 mm | |

| Max. travel of x-axis | 720 mm | |

| Max. travel of z-axis | 280 mm | |

| Max. travel of Y-axis | 100 mm | |

| Rapid speed (x-axis/z-axis) | 36 m/min | |

| Reposition accuracy | 0.005 mm | |

| Motor | Spindle servo motor | 4.4 KW |

| Spindle speed | 3000 rpm | |

| X/Z-axis servo motor | 1300 W | |

| Y-axis servo motor | 750 W | |

| Servo motor for power unit | 750 W | |

| Tools | Gang type tools | 3--5 |

| Total living power tool unit | 2 | |

| Living tool holder size | ER20/25 | |

| Other | Total power | 7KW |

| Size( L x W x H ) | 2070*1580*1870 | |

| N.W. | 2550 KGS |

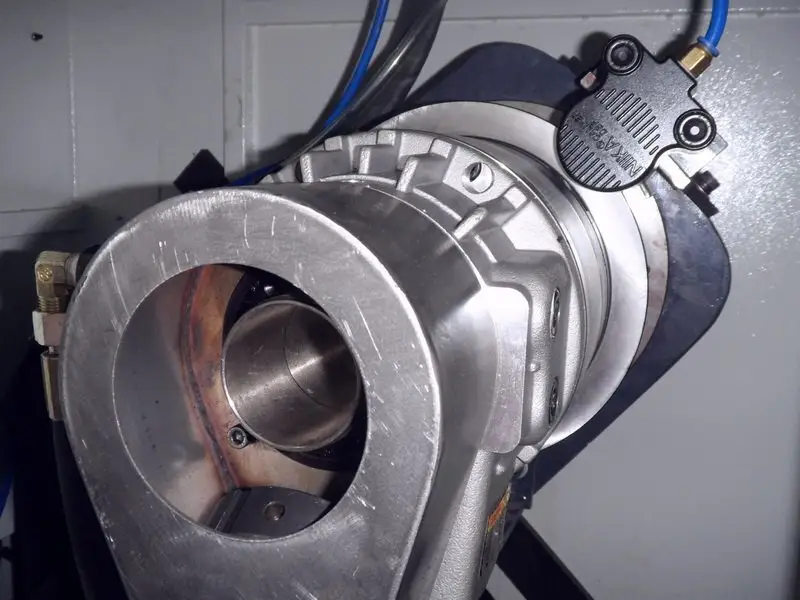

(1)the A2-4 spindle is from Taiwan

(2) use the P4 level NSK bearing from Japan

(3) the high speed up to 6000 rpm.

(4) the max. through bar material diameter is 35mm.

(5) can instal 5 inches maual chuck

(6) can instal 5 inches hydraumatic 3-jaw lathe chuck

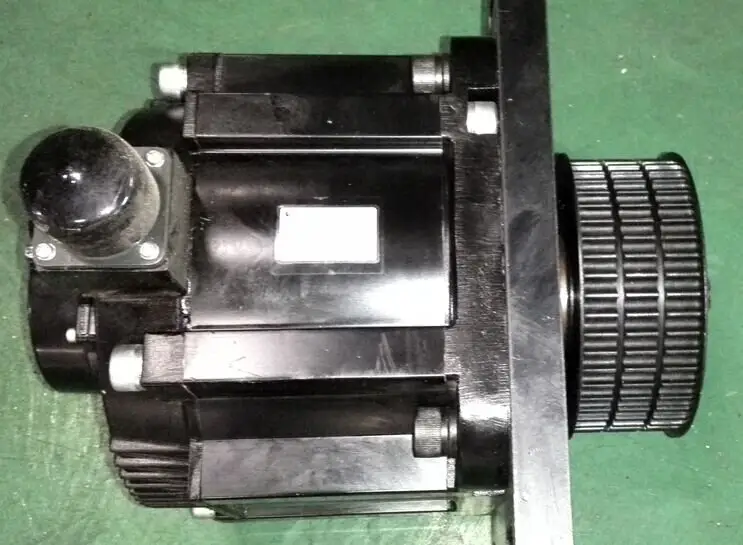

(1)the spindle motor is from Yaskawa

(2) 4.4KW spindle motor

(3) the high speed up to 4500 rpm.

(4) the servo motor can get the bigger torque when low turning

X/Z axis servo motor and servo pack

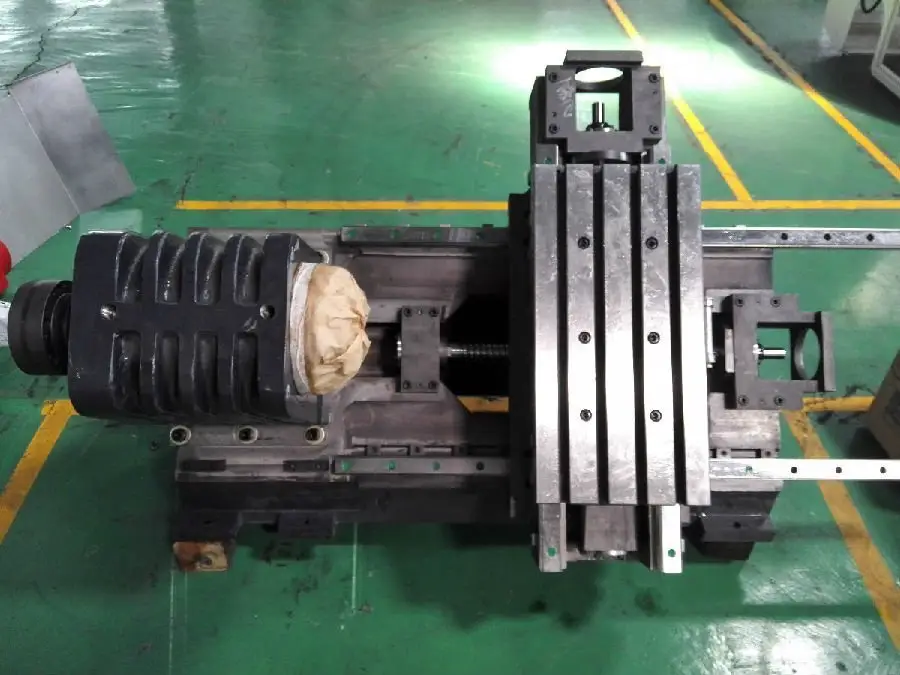

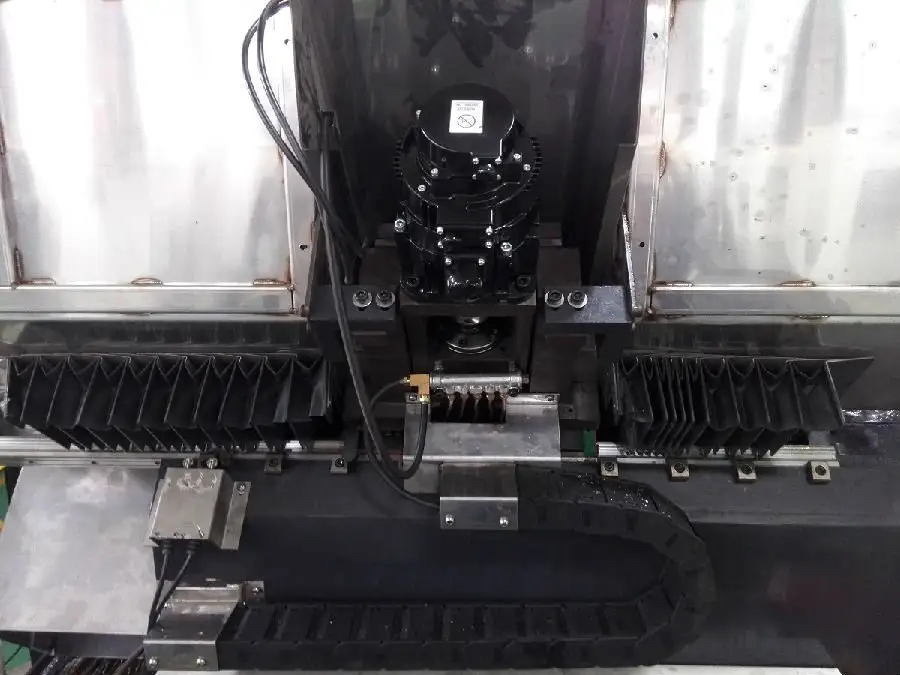

(1) gang type cnc lathe machine body.

(2)X-axis and Z-axis assembly

Linear Guide and BallScrew

NSK bearing

P4 level

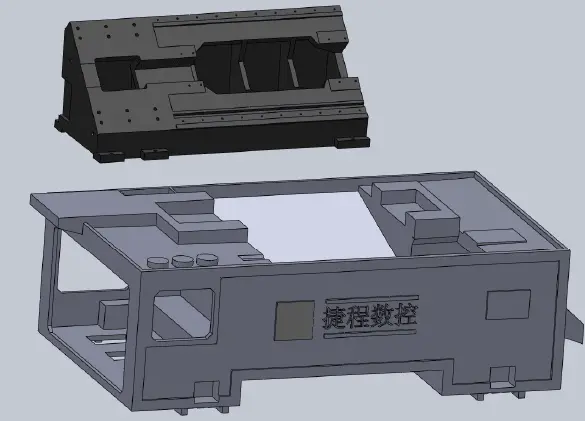

(1) gang type cnc lathe machine body.

(2) X-axis and Z-axis assembly.

(3) slanting bed for gang type.

(4) HIWIN lead screw and couple

(5) NSK bearing.

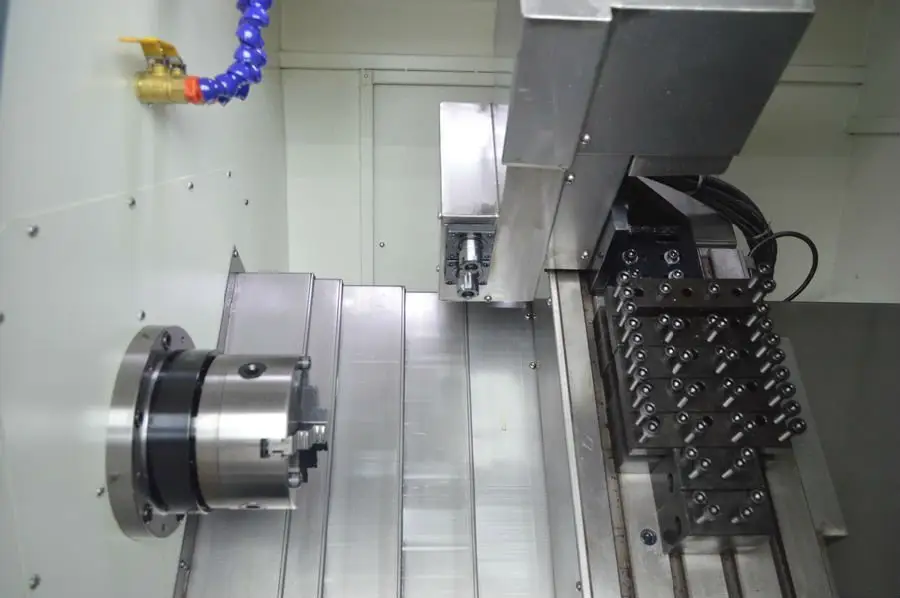

(1) full cover for gang type cnc lathe machine CFG46Y2 model.

(2) stainless steel for cover.

(3) gang type can instal 6 to 7 tools.

(4) free provide 2 long and 2 short tool holders

(5) Y axis living tool size is ER25, tools diameter is 1~16mm

(1) 13000W YASKAWA servo motor for X-axis

(2) 1300W YASKAWA servo motor for Z-axis

(3)850W YASKAWA servo motor for Y-axis

(4) 1300W YASKAWA servo motor for living tool

(5) 36 m/min for travel speed

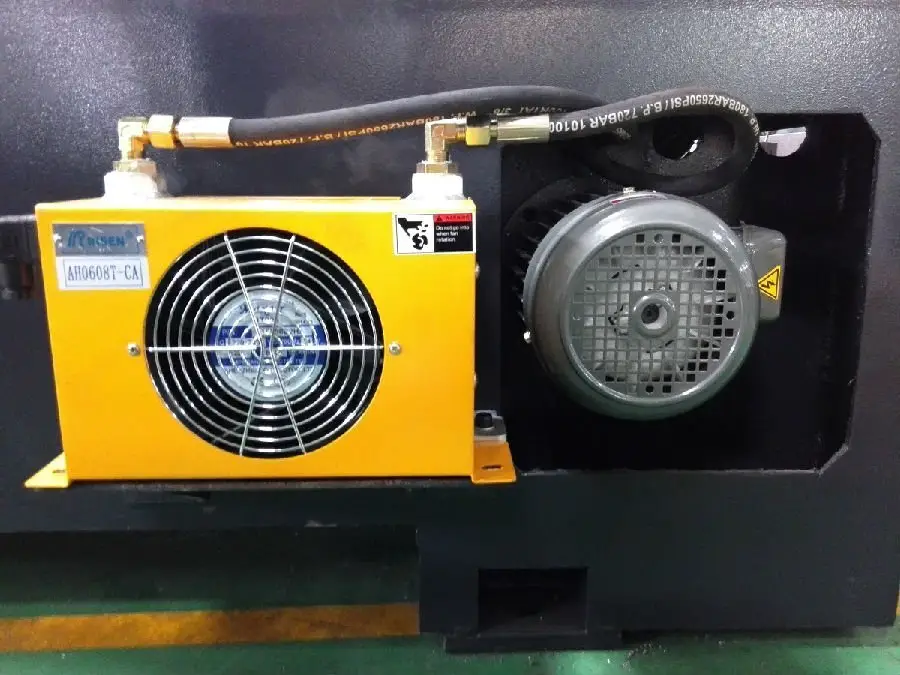

1) hydraulic cylinders from TAIWAN.

(1) hydraulic cooler

(2) hydraulic pump motor use 2 hp

(1) electrical cabinets for4 axis type cnc lathe machine

(2)YASKAWA servo pack for spindle motor

(3) servo motor driver from YASKAWA for X-axis and Y-axis motor

(4) Schneider switch

(1) controller panel

(2) controller can be change for SYNTEC,GSK and so on

(3) controller can be set in English

(4) we have JSTOMI and JSWAY two logos.

pressure gate

(1) all cnc lathe machine tool with HTS CE certificate

(2) all cnc lathe machine tool with ECM CE certificate

PACKING AS BELOW

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. enjoys a high reputation in market.

2. JSWAY is a famous brand which has advanced production technologies.

3. We take full responsibility for our impact on the environment, and therefore not only do we constantly strive to reduce any such impact in the course of our operations but also consistently adhere to the legal regulations governing environmental protection. Contact! We are committed to improving our brand recognization. By demonstrating a positive image to clients and partners, we actively partake in various business activities to make our brand known more by people. We think sustainability is an important part of our business. We’re dedicated to promoting environmentally sound production practices that help minimize waste and reduce harmful emissions to the air, water and land. The company undertakes its social responsibility through a series of business or communities actions. We are active in protecting the local mother river, planting trees, or cleaning the streets. Contact!

MJ series sliding table panel saw MJ-45M

Dimension of sliding table | 1600x375mm |

Gross cut of capacity | 1600mm |

Tilting saw blade | 45 degree |

Maximum height of cut | 70mm/50mm |

Maximum main saw blade size | 305x30mm |

Scoring saw diameter | 120x20mm |

Main power /Scoring power | 3.0KW/0.75KW |

Speed of main saw spindle | 4500/5500rpm |

Speed of scoring saw blade | 8300rpm |

Net weight/Gross weight | 400kgs/500kgs |

Table height | 840mm |

Package size | 1100*1070*980mm/1900*450*310mm |

Pre-sale service support:

According to each customer's demand and budget, we offer you the professional solution, process flow design and production equipment. More importantly, we welcome every customer to visit our factory and working machine in the site before placing the order. We will arrange cars, hotels and translators for the visiting customers.

During-sale service support:

Assist clients to finish the factory planning. Before delivery equipment to customer s, complete debugging and checking. Provide a full instruction manual for the whole system. Provide technical guidance for the installation and use of the unit, including installation advice and electrical connection. Provide unit debugging and training for the operation of the machine on the working site and coordinate the customers with check and acceptance of the unit.

After-sale service support:

Send technicians to installation site for the guidance, equipment adjustment and training. Provide high-quality spare parts throughout the year, and the maintenance technicians are always ready to provide technical help.