JSWAY | Leading CNC Lathe Manufacturer Since 2007

JSWAY WU800 6 Axes Interpolate Y-Axis Dual Electric Spindle Dual Upper Power Turret Machine138

- JSTOMI adheres to the 'customer first' principle to provide quality services for customers.

1. JSWAY is manufactured in accordance with set quality norms.

2. The product quality has been strictly controlled by professional QC team.

3. Thanks to its fuel efficiency, the product greatly helps companies reduce CO2 emissions during operation and increase greener footprint in the long run.

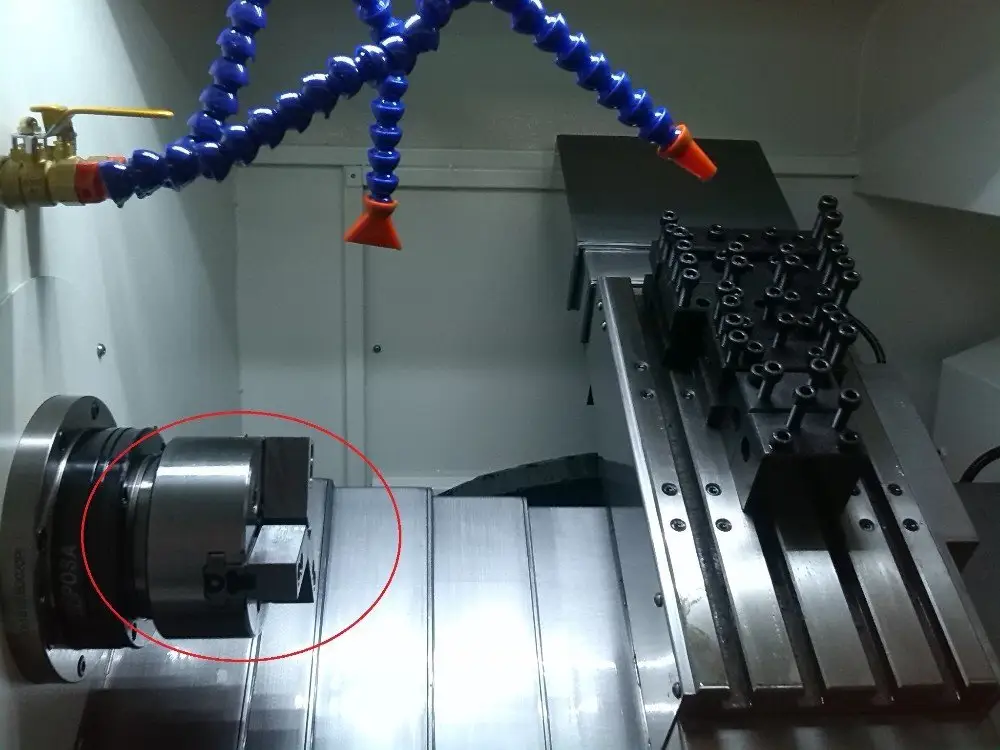

Easy To Install High Speed and Long Service Life 3 Jaw

Power Chuck

Features

1. Patented product, cylindrical form of connection, easy to install, in line with industry

standards.

2. With a large through-hole, high speed and long service life, the chuck equipped with a

standard soft jaw can be used for high-precision machining of clamp and rod parts.

3. It is applicable to all kinds of CNC lathes and automatic feed processing equipment,

(it is available for hollow three-jaw power chuck with rear through-hole structure, and the

connection method is the same as solid pneumatic chuck).

| Model | OP-204 (-) | OP-205 A24 | OP-206 A25 | OP-208 A26 | OP-210 A28 |

| Plunger stroke mm | 10 | 10 | 12 | 16 | 19 |

| Jaw stroke (diameter) mm | 5.4 | 5.4 | 5.5 | 7.4 | 8.8 |

| Max. pull force(kgf) | 14 (1428) | 17 (1730) | 21 (2140) | 33 (3360) | 42 (4280) |

| Max. gripping force (kgf) | 28 (2850) | 35 (3570) | 56 (5710) | 82 (8360) | 108 (11010) |

| Max. hydr. Pressure (kgf/cm²) | 2.3 (23.5) | 2.8 (29) | 2.7 (28) | 2.5 (26) | 2.6 (27) |

| Max. speed (r.p.m.) min-1 | 8000 | 7000 | 6000 | 5000 | 4200 |

| Thru-hole (diameter) mm | 26 | 33 | 45 | 52 | 75 |

| Standard soft jaw height mm | 23 | 30 | 36 | 38 | 42 |

| Gripping range mm | Φ7-Φ110 | Φ10-Φ135 | Φ13-Φ169 | Φ13-Φ210 | Φ30-Φ254 |

| (with standard soft jaws) kg | 3.8 | 6.1 | 12.5 | 21.9 | 33.7 |

| Matching cylinder | P0928 | P1036 | P1246 F1246S | P1552 F1552S | P1875 F1875S |

DRAWING

1. We are a manufacturer of slant bed cnc lathe machine for 10 years ,Technology in the industry is come

out in front.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Our Advantages and quick delivery, Competitive price ,high quality and long term service to out

customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements

of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools

on table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,We can

also according to your need to change the configuration. Thus pls provide us your machining

drawing, we are very glad to design a specific process solution for you and recommend you a

proper cnc machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and strong

machine tool research and development capability. We are very willing to offer you customized

highly-efficient equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more quickly

and efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy all the

Equipments for your market ,at the mean time the customers can enjoy the long-term technical

advisory services in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements

of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term

service to out customers.

Welcome to contact us if need any more information.

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is a specialty provides high quality .

2. Our products have been widely sold to Europe, America, the Middle East, and South-Eastern Asia. Most of our products are produced based on market trends which exactly cater to customers' needs.

3. We understand that our company's social responsibilities go beyond our status as just a manufacturer – our employees, customers, and the wider community look to us to lead the way and set an example. We will not live up to them. We are responsible for the environment. We partner with a range of organizations that are creating meaningful change for the environment. We put sustainable development as our top priority. Under this task, we will invest more in introducing green and sustainable manufacturing machines which generate less carbon footprint.

Raymond Mill/gypsum powder line/gypsum powder machine

Raymond mill is a common use grinding equipment, it is mainly applicable for high fine milling of non-flammable and non-combustible chemical materials in mining, chemical, construction industry whose Moh’s hardness is under 9.3 and humidity is under 6%.

Technical Parameters of Raymond Mill

| Model | 4525 | 4119 |

| Feeding Size(mm) | ≤30 | ≤25 |

| Szie of Finished Product(mm) | 0.173-0.044 | 0.173-0.044 |

| Shift Output of Different Material Finesee(t) | 16-176 | 8-78 |

| Rotate Speed of Central Shaft(r/min) | 82 | 105 |

| Diameter of Pulverizing Ring(mm) | 1770 | 1400 |

| Diameter of Pulverizing Roller(mm) | 450 | 410 |

| Height of Pulverizing Roller(mm) | 250 | 190 |

| Main Motor | Y315M-4-132 | Y280S-4-75 |

| Fan Motor | Y315M-4-132 | Y280S-4-75 |

| Analyzer Motor | YCT250-4A-18.5 | YCT200-4B-7.5 |

Working Principle of Raymond Mill

The grind roller rolls on the grind ring under the effect of centrifugal force, the materials scooped up by the relieving tool are sent in the middle of roller and ring, they will be ground into fine powder under the effect of ground pressure, and then send the powder like materials into the analytical engine. The materials whose fineness meets the requirements will pass the engine, while those whose are not meet the requirements will be back to the grinding chamber being ground.

Features of Raymond Mill

- The Raymond mill has a stereochemical structure, which needs small floor space.

- Uniform fineness of final products, 99% screening rate.

- The main engine of the mill drives smoothly and stably because the transmission gear adopts sealed gear case and belt wheel.

- The main parts of the Raymond mill are made of high quality rolled steel, the wear-resistant parts adopt high-performance wear-resistant materials, so it has high wear-resistant property.

- Easy maintenance.

The raymond mill will start delivery in 30 days after payment. It will be packed in export standard container, it's main motor and spare parts will be put in the sealed and water-proof wooden case.

We promise the raymond mill will be shipped to you timely and safely.