JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY WU800 6 Axes Interpolate Y-Axis Dual Electric Spindle Dual Upper Power Turret Machine116

- JSTOMI abides by the service principle of 'customers from afar should be treated as distinguished guests'. We continuously improve the service model to provide quality services for customers.

1. The design of JSWAY is carried out using CAD technology. The design is done by CAD technicians who can create a 3D bathroom scene where the product is placed in.

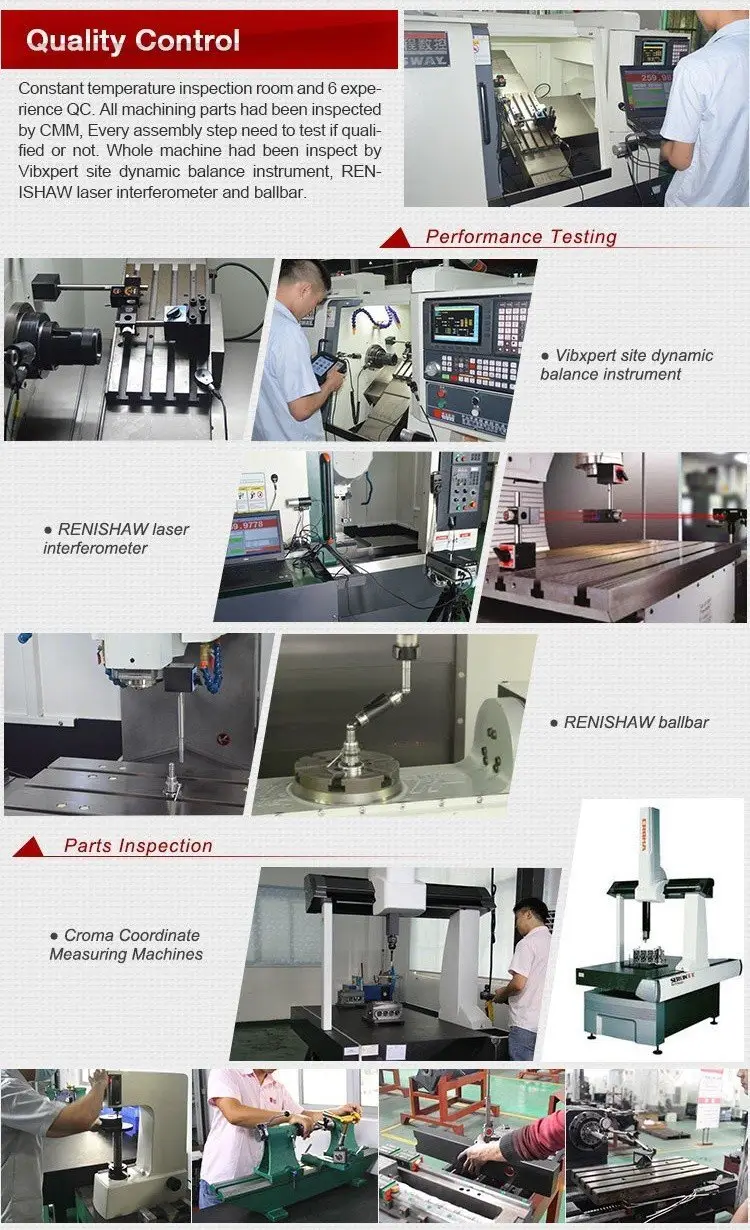

2. The product has been rigorously tested on various aspects and its quality has been recognized by professional QC team.

3. Its quality will be checked out with 100% attention by our QC team.

4. The product is available at competitive prices and is widely used in the market.

5. The product, used by an increasing number of people, has an extensive application prospect.

5-Axis Y-Axis CNC Multi-Purpose Mini Hobby Metal Lathe

Machine CFG46Y3+2

Features of 5-Axis y-axis cnc lathe machine tool CFG46Y3+2:

1. Y axis have engraving function.

2. This model is for turning, side milling and drilling.

3. Big space for machining, Z/X axis travel is long.

4. Y-axis have 3 living tool and X-axis with 2 tools.

5. Japan gear, low sounds, high precision for Y axis living tool.

6. Y axis living tool max speed is 4500rpm .

Technical Parameter for 5-Axis y-axis cnc lathe machine tool CFG46Y3+2;

NC | TAIWAN/GUANGZHOU | LNC/SYNTEC/GSK |

Spindle | TaiWan Posa | A2-5/46 spindle |

X.Z axis servo motor | Japan YASKAWA | 1300 W |

Y axis servo motor | Japan YASKAWA | 750 W |

Spindle servo motor | Japan YASKAWA | 4.4 KW |

Spindle servo pack | Japan YASKAWA | 5.5 KW |

Lead screw/lead rail | TaiWan HIWIN/PMI | C3 , level two |

Bearing | Japan NSK,Germany FAG | P4 level |

Coupler for lead Screw | From Germany | high Precision |

Parameter | ||

Capacity | Spindle bore | ¢56 mm |

Max.material diameter | ¢45 mm | |

Max.machining diameter | ¢350 mm | |

Max.lenght of machining | 200 mm | |

Max. travel of x-axis | 720 mm | |

Max. travel of z-axis | 280 mm | |

Max. travel of Y-axis | 155 mm | |

Rapid speed (x-axis/z-axis) | 36/36/20 m/min | |

Reposition accuracy | 0.005 mm | |

Motor | Spindle servo motor | 4.4 KW |

Spindle speed | 3000 rpm | |

X/Z-axis servo motor | 1300 W | |

Y-axis servo motor | 750 W | |

Servo motor for power unit | 750 W/850 W | |

Tools | Gang type tools | 3--5 |

Total living power tools unit | side 3/side 2 | |

Living tool holder size | ER20/25 | |

Other | Total power | 7KW |

Size( L x W x H ) | 2025*1385*1910 | |

N.W. | 2900 KGS |

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in front

in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements

of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,

2-3 tools on table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,

We can also according to your need to change the configuration. Thus pls provide us your

machining drawing, we are very glad to design a specific process solution for you and

recommend you a proper cnc machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and

strong machine tool research and development capability. We are very willing to offer

you customized highly-efficient equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more

quickly and efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy

all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the

requirements of guests.Our Advantages and quick delivery, Competitive price ,high

quality and long term service to out customers.

Welcome to contact us if need any more information.

Company Features

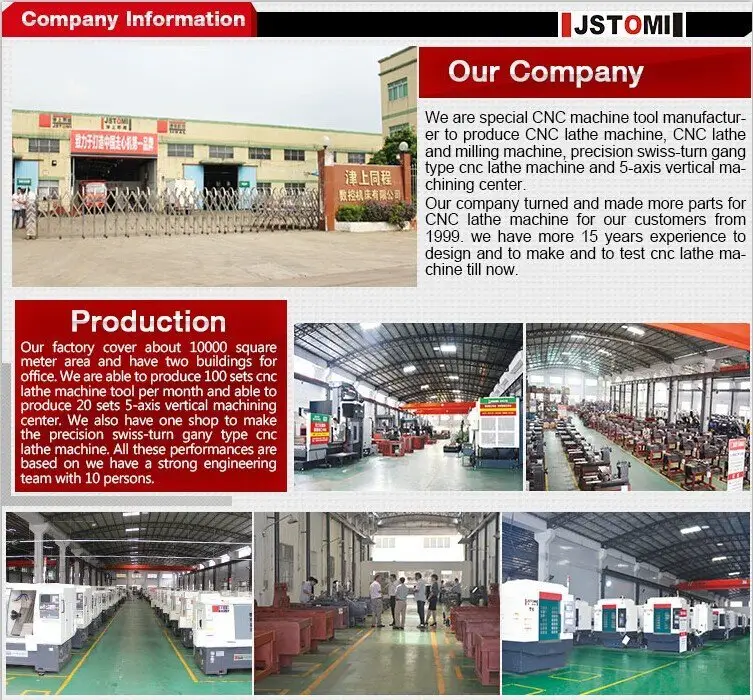

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is a world market leader in .

2. To increase its competence in the market, JSWAY largely invested into optimizing the technology to produce .

3. We’re constantly striving to improve the products we supply, the services we deliver and the positive impact we make. Our mission is not just to succeed in this market. We aim to lead it towards a more ethical future. Contact! JSTOMI CNC Machine will continue to develop to meet rapidly changing customer demands. Contact! We always adhere to the principle of 'quality first'. Good quality products will help us win more customer. Hence, we will conduct specialized education and technical training to the workers, and work together to improve product quality. We are committed to environmental protection and resource conservation. We prevent or reduce pollution and develop energy-efficient products to maximize our sustainability.

Our company can supply complete production lines and machines according to your requirement. We supply many different sizes of C Purlin Machine with our auxiliary equipment. We have gained a good evaluation from users because of advanced technology, perfect quality and after-sale service.

Machine Details:

1. Suitable Plate Material: thickness 1.5-2.0mm, Galvanized steel or blank steel

2. Working Speed: 12-15 meters / min

3. Forming Steps: 19 stations, drive by gear boxes

4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5. Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining

6. Driven system: Chain Driven 1.5 inches 20A double chain with longer shafts

7. Main Power with reducer: 22KW WH Chinese Famous

8. Cutting: Hydraulic Cutting Cr12mov

9. Material of Cutting Knife: Cr12Mov, Quench HRC58-62

10. Hydraulic Station Power: 4KW Wuxi Wanshen Famous Chinese Brand

11. The whole machine is controlled by industry computer-PLC.

12 PLC--Panasonic, Japan English and Chinese Language

13 Touch Screen--Panasonic Japan

14 Encoder--Omron, Japan

Machine Loading:

1) FOB Tianjin

2) Payment: 30% T/T deposit, and pay the balance before shipping.

3) Delivery time: 60 working days.

4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer.

5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc.

6) Installation and training:

1. If buyers visit our factory and check the machine, we will teach you how to install and us the machine, and also train your workers/technician face to face.

2. Without visiting, we will send you user manual and CD to teach you to install and operate.

3. COST OF INSTALLATION:

The buyer should pay the installation charges (USD 100 one man one day). To the seller’s appointed account by T/T before the seller’s technicians go to the buyer’s factory. The buyer pays the seller’s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

1. Q: What is the productivity of concrete mixer and concrete batching plant?

A: The productivity of concrete mixer ranges from 6m3/h to 100m3/h.

The productivity of concrete batching plant ranges from 25m3/h to 180m3/h.

2. Q: Warranty period your company giving for PLC/MOTORS?

A: 12 months after installation.

3. Q: Operating system warranty and any extra unit giving with plant?

A: Operating system and any extra unit warranty: 12 months after installation

4. Q: Computer warranty?

A: 12 months after installation.

Thanks for your time!